After installing windows in a house made of timber or logs, mounting and expansion gaps remain in sight. In addition, the ends of the logs remain visible, which rarely look attractive. Platbands hide these details and extend the life of the windows.

Why do we need platbands on windows in a wooden house

Platband is an architectural element, framing a door or window opening. The design is extremely simple - these are 4 boards or 4 fragments of a different profile, which cover the gap between the casing or the slope of the log house.

Functions:

- Hides the gap between the window frame and the wall. This prevents moisture and snow from entering the wall.

- The framing is used to highlight the window opening. It is important for the appearance of a building that windows and doors create a certain rhythmic structure.

- Serve as a window decoration and emphasize the style.

The gaps between the window structure and the wall are foamed with polyurethane foam. However, this material also does not look very aesthetically pleasing and deteriorates under the influence of moisture and frost. The platband protects the filler.

Varieties of window trims

At the place of installation, platbands are distinguished:

- External - placed on the side of the facade. Materials for them must be resistant to rain, frost, sun, snow. The exterior is matched to the style of the building.

- Internal - made of composite lightweight materials like MDF, glued board, plywood. When installing, they must be connected to the slopes. It is not uncommon to play the role of addons.

- Special - accessory of plastic windows. They are characterized by a complete set of all devices, including fasteners: corners, clamps, clips.

The purpose of the platbands affects the design and type. On the first basis, they are divided overhead and telescopic.

Overhead

A simple and popular option. In fact, this is a rail cut along the length of the opening. The platband is fixed to the wall with nails, screws, glue. They are very popular due to their low cost and ease of installation.

Overhead models are fixed over the window frame and facade.

Telescopic

A more complex design, including inner and outer framing. L-shaped strips fit tightly to the slopes and close with the groove of the window frame. The inner part of the casing can be supplemented with a second plank of any size. This allows them to be installed in a window opening of any depth.

The advantage of the telescopic model is the ability to mask additional and uneven gaps arising from curved walls and alignment of the window structure. Mounting and dismounting the bezel is equally simple.

No fasteners are required to install telescopic platbands.

Requirements and Recommendations

Cashing on windows is a very undemanding design. Wooden linings are quite compatible with metal-plastic ones, MDF models are combined with wooden ones.

The recommendations for choosing are the simplest:

- The material and construction are rigidly dependent on the device of the window only if they are components of the complete set. It is necessary to consider how such platbands will affect the facade.

- When choosing a fastening system, take into account that open nail heads rust quickly and can leave ugly drips that are difficult to remove.

- The platband cannot be fixed directly to the frame - this is the only limitation. The house shrinks; both the window and the platband can warp.

- Do-it-yourself platbands on windows in a wooden house are better made of the same wood as the walls. In this case, the shrinkage factor will be the same.

If the house is decorated with a carved frame of complex shape, soft rocks are taken for it: alder, linden, aspen. It lends itself to processing, holds the thread well.

Selection of materials

Carved or simple platbands can be made from many materials. In fact, the choice is limited by practicality, durability, cost. An important criterion is compliance with the stylistic design of the building.

Wood

A platband made of wood is the best option for a log house. It is not a matter of shrinkage or other characteristics of the product, but of decorativeness. Only wood can be used to make truly unique, beautiful things.

When choosing a material and design, consider the following:

- Power frames on the outside are made of rocks resistant to water and cold. These are oak, larch, ash, which only become stronger under the influence of moisture.

- Carved decorative overlays are cut out of soft wood - alder, linden. Since such material is poorly resistant to changes in humidity and cold, they are treated with stabilizing impregnations.

- For a patterned casing without overlays, simple patterns in a slotted style are selected. Hardwood is difficult to process, and a special tool is required for carving.

- All elements of the external window structure are carefully treated with waterproof compounds.

Oil impregnation is often used to protect wood decor. The product changes the color of the wood, while maintaining the structure. This feature must be taken into account.

Plastic

A plastic cashier is not the best option. The technical characteristics meet the requirements, but the decorative qualities are not satisfactory. Even when reproducing a tree species, this imitation looks cheap and unconvincing.

Plastic overlays are used in frame buildings made in the style of constructivism, techno, and Canadian. Here, they are not required of beauty or originality. Another option is imitation carved elements made of polyurethane or other hard plastics.

Plastic platbands are attractive due to their low price and long service life. It is not necessary to look after them like wooden ones.

MDF

High density particle board. The main advantage of the material is its low sensitivity to the action of water: MDF does not swell and does not shrink, does not change its size and configuration over time. It perfectly imitates wood, repeating color and texture.

Internal platbands are made of MDF. This is the best material for telescopic models. External MDF elements may only be installed in dry regions. Chipboard cannot withstand direct contact with water, snow and cold.

DIY preparation and installation of platbands

It is not so difficult to make simple or carved platbands.

Advice:

- Before making or buying, window structures are carefully measured. The slats must be wide enough to completely cover the contour of the frame.

- The elements of the installation, if they are not plastic models, are treated with antiseptics to protect the material from fungus and insects.

- The joints between the window structure and the wall are waterproofed.

- The installation must not be carried out in frosts below -15 C, in heavy rain or snowstorm.

The principles of installation of carved and simple platbands are the same.

Cash production

A simple model performs a technical function, therefore, they take hardwood or conifers for it - pine, larch.The design includes 4 harness boards, 2 canopy supports and a canopy. The width of the strapping boards is from 90 to 145 mm, and the casting board is 175 mm.

- Cut the props with a jigsaw.

- Saw out the side boards. The length of the rack exceeds the opening by 2 widths of the rail. The length of the top board is equal to the low tide. All boards are beveled at 45 degrees for corner joining.

- The visor is made beveled at the edges, and a chamfer is cut out in front for an ebb.

The installation of the frame is performed on the casing or frame. Fixation is allowed only on a wooden spike.

Manufacturing of carved platbands

With their own hands, they often make slotted platbands and overhead. In the latter case, the details of the ornament are made separately, and then glued to the board. For the first option, you will need a board up to 30 mm thick, and for the invoice - up to 10 mm.

- A drawing is applied to the surface of the treated board. Consider that the patterns should be mirror-opposite.

- The internal cuts are made according to the drawing with a jigsaw. Then the pattern is cut along the outer lines.

- The edges are smoothed and sanded using rasps and sandpaper.

It is better to put overlay elements on glue, as self-tapping screws provoke cracks.

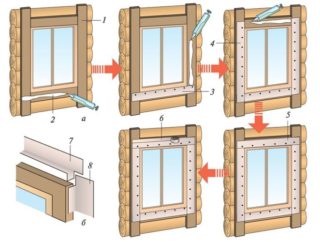

Installation of platbands

Installation is carried out on wooden pins. Such fasteners change volume along with the material and do not slip out of it when the wood dries. The scheme is simple.

- Assemble parts into one piece on a thorn. Fastening is duplicated with glue.

- Distinguish between blind or through fasteners. In the first case, holes are drilled for the projections in the platbands and the frame. In the second, the frame is immediately applied to the casing, holes are drilled for nails and pins on the glue are hammered into them.

- For deep fastening, first on the frame and frame mark the installation locations of the spikes and make holes for them.

- The pins are made of hard wood. The diameter of the spike is 0.5 mm larger than the diameter of the holes: this is how a tight joint is achieved.

- The pins are preliminarily greased with glue.

To protect the platbands from the action of water and the sun, they are varnished, painted, treated with stains or oils. The coverage needs to be updated periodically.