Decorative panels for finishing a doorway are chosen according to the option of installing the box, the material of the canvas and the requirement for appearance. Installation of platbands on interior doors is carried out using hardware or liquid nails, but the finishing element always performs special functions. The framing masks the gap between the patch and the vertical wall, hides the wiring when needed and gives the aisle a nice look.

- Varieties of platbands for interior doors

- Wooden

- Made of MDF

- Metallic

- Veneered

- Laminated

- Mounting methods

- Liquid nails

- With finishing nails

- With self-tapping screws

- Beak fastening

- Necessary tools for the job

- Docking rules

- 45 degree angle

- 90 degree angle

- Telescopic platbands

- DIY installation instructions

- Dismantling of platbands

Varieties of platbands for interior doors

Monolithic strips and models with channels inside the structure are produced. Electric wires are laid in the grooves.

The platbands are divided according to the appearance of the front side:

- Smooth. A simple and demanded form is distinguished by its versatility and low price.

- Semicircular. They have rounding of various radii along their entire length. Barely noticeable or pronounced curvature is chosen depending on the preferences of the owner.

- Embossed. They have a variety of convex shapes on the surface. Drawings are made on specialized equipment, which adds value when sold on the market.

By color, platbands are selected to match the door block or made contrasting, while taking into account the type of wall decoration.

Wooden

Eco-friendly products that remain durable and attractive throughout the life of the work, fit almost any interior, door style. Straight, embossed varieties of door frames are made of wood.

In damp rooms, you can fix hardwood trims such as oak, maple with an extra layer of veneer or laminate. Wood without a topcoat is treated with paint or varnish. Carved casing will effectively accentuate the interior of the aisle in the style of classic or antique decoration.

Made of MDF

The budget option is cheaper than wooden planks, but the performance is almost the same, and sometimes even better. The material does not rot, so its service life is increased. Externally, MDF planks do not differ from natural wood, production designers successfully select the texture and pattern of products.

Disadvantages include the ability to absorb moisture, which causes the planks to swell. MDF is not used in the bathroom, sauna or steam bath. A natural wood veneer is placed on the front surface, a laminating layer of their PVC film, sometimes the products are painted.

Metallic

It is customary to use the option of a metal frame for the entrance group, but indoors such elements also look advantageous. The advantage is moisture resistance and durability. Metal strips are suitable for loft style, high-tech, minimalism, they are placed on interior door blocks made of plastic.

In production, metal (stainless steel, aluminum) is coated with a layer of epoxy-based powder paint, which is then fixed in heating chambers. The cladding serves for a long time and does not deteriorate under the influence of negative factors.

Veneered

A thin coating of high quality wood called veneer is applied to the surface of the trims.The thickness is 0.1 - 1.0 mm, and the main body of the product is made of pressed natural fibers.

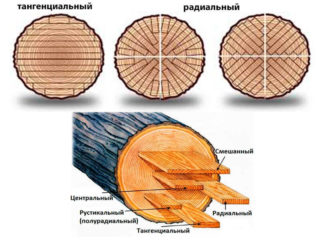

Veneer can be:

- shelled - wood chips obtained on machine tools;

- planed - made during the planing process;

- sawn - sawn solid wood into thin layers.

The veneer layer is made natural with special impregnations, such products convey the correct structure of the wood. The second option is a dyed or stained layer, while it is possible to expand the range of colors.

Laminated

The difference from the veneered cassette with a laminate is that a film is applied to the surface, and not a thin veneer.

The design of the laminated platband includes layers:

- the lower layer for stabilization increases rigidity, sometimes a substrate is glued to it for sound insulation;

- the base or bearing layer consists of durable fiberboard with moisture-resistant impregnations, a fastening lock is cut out in it;

- the decorative outer layer is paper with an appropriate texture pattern.

They cover everything with a polyvinyl chloride film that protects against moisture, shock, abrasion. The class of wear resistance depends on its thickness and qualities.

Mounting methods

Platbands of various shapes and materials differ in installation and the specifics of the design of the ends. The fastening is determined depending on the method of installing the patch and the type of framing strip.

There are fixation methods:

- liquid Nails;

- various finishing hardware;

- self-tapping screws;

- special beaks.

Some fastening methods require the preparation of parts, for example, holes for nails are cut out in MDF platbands or for drowning hats. Use a wax based camouflage stick.

The self-tapping method is common, as platbands are attached most often.

Liquid nails

The composition makes installation of platbands on interior doors without nails. You can put the frame so that the place of fixation will not be determined. The disadvantages include weak strength and inconvenience when removing the platband, if you need to keep it intact. Liquid nails are taken to set the casing on a flat wall.

The glue is produced in tubes. The composition is spread on the back of the bar. For gluing, it is enough to press the element and hold for a minute.

With finishing nails

They choose hardware with a length of 4 cm, but the size should take into account the thickness of the part. The nail goes through the bar and sinks 2 cm into the tray.

Options for the design of hats:

- painted with a wax rod;

- immersed in the body of the clypeus, for this, a hole is pre-drilled to a depth of 3 mm along the cross-section of the size of the nail head;

- cut off the top of the nail with side cutters.

Fixation points are marked on the cashing with a uniform step, a distance of 50 cm is taken as standard. Holes are drilled along the thickness of the hardware so that there are no chips when hammering. The holes are filled with special paste or suitable pieces of wood.

With self-tapping screws

The outdoor attachment method is popular for its ease of use. Before making the platbands on the door, you need to pick up the caps in the form of flat circles, which are put on the top of the screws. They are sold in hardware stores, while there is a large selection of colors.

When fixing internally with self-tapping screws, you need to attach the platband from the back to a professional fixture. The structure is not broken, the cash remains intact. Sometimes a combined method is used using hardware and liquid nails.

Beak fastening

The method is based on the use of a lock that resembles a beak. The casing has a ledge along its entire length, and the box is equipped with a mating groove. To install, you need to press the bar until you hear a click. The enclosure is attached quickly and easily, while self-tapping screws and nails are excluded.

Sometimes, during dismantling, the beak-shaped MDF strip fastener is stratified, which leads to relaxation during subsequent installation and operation. Spontaneous loosening is prevented by applying glue to the joint so that the joint is strong.

Necessary tools for the job

The platbands are cut to size using an electric jigsaw or a hacksaw. With the help of tools, adjust the desired angle or make a cross section.

Installation tools:

- electric drill with several sizes of wood drills, lightweight screwdriver;

- Phillips screwdriver, small hammer, side cutters;

- tape measure, pencil, construction square.

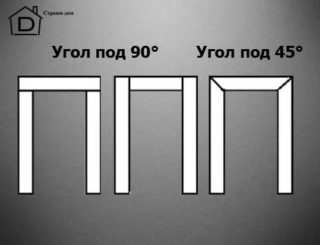

Installation is done exactly at an angle of 90 or 45 °. To withstand the degrees, a miter box is used, while the saw blade is placed exactly along the opposite cuts in the tool. The miter box is made of metal, plastic, wood, sometimes it is combined with a turntable on which the saw can be mounted.

Docking rules

Types of cladding are produced:

- external, the corners of which are cut at 45 or 90 °;

- internal or telescopic - in the form of the letter G.

The width of the cashing is taken according to the size of the slot that needs to be closed, more often they put elements 6 - 12 cm.For small rooms, it is preferable to put narrow strips, and in large rooms wide embossed varieties look beautiful.

45 degree angle

Such a connection looks organic and is used most often, platbands fit with any form of the front surface. Use a miter box, and if not, use a protractor. To determine the corner point, a vertical bar is attached and a line is drawn along the outer side. Then they also do with a horizontal lining and make a line on the upper side to intersect with the vertical one.

The height is measured from the floor to the point of intersection of the lines. Provide recesses in the body of the clypeus if it stands on the side of the hinges. A workpiece is placed in the miter box, and an angle is cut off at 45 °. The elements are baited onto the box and check the coincidence of the lines. Fasten in the chosen way.

90 degree angle

A right angle connection is used for flat strips or with very small rounding elements on the sides.

There are two options for joining:

- top - the horizontal casing is located between the vertical parts, the cut end is closed with side posts;

- lateral - when the top bar covers the standing panels, while the end is visible from the side.

The second method is almost never used, since you need to decorate the cut off part. Acrylic-based paints and varnishes are used for camouflage.

Telescopic platbands

L-shaped panels are fixed in a ledge-groove method. Installing telescopic platbands requires care to get an accurate connection. If the box is narrow and the wall is thick, addons are acquired. In this case, make sure that there are special grooves in the design of additional elements. More often the size of the telescopic platbands is enough so as not to use extensions.

Telescopic models dock at 45 °, which adds complexity, but looks aesthetically pleasing. Can be connected in a rectangular manner if appearance is not important. Glue is not used, since the elements are fastened by snapping.

DIY installation instructions

The first is the plank on the hinge side. Next, mount the second vertical rack. The upper platband is placed last. At first, all the details of the strapping are fixed to a minimum in order to be able to fit.

The final fixation is done in the chosen way. Glue is applied to the back side, cashing is nailed, self-tapping screws are screwed or locks are latched.Pay attention to the sealing of joints and holes of hardware, process the visible ends.

Holes from the installation of nails and screws remain on the front surface. They need to be sealed with a colored sealant to match the main color scheme. Wooden platbands are varnished, and laminated, veneered ones are left as they are.

Loose joints are treated, into which an acrylic-based sealant is placed. Subsequently, such places are tinted with acrylic paints. Silicone sealants are not used, since paint does not adhere to the surface. If there are under-screwed screws or protruding nails, they are installed to the installation depth.

Dismantling of platbands

Determine the method of initial fastening and, depending on this, unscrew the hardware. The platbands on the nails are carefully pry off with the edge of an ax and pulled away from the box along the entire perimeter. The removable ones on the beaks are snapped open, while trying not to damage the lock.

If the strips are removed for replacement, they do not worry about safety, but they do the work carefully so as not to damage the box.

Yes, it will take a long time to catch corners