Soft roofing is a collective definition of roof covering materials with optimum performance characteristics. It can be rolled or piece. The product is lightweight and easy to cut. Installation of a soft roof can be done independently.

Materials for arranging a soft roof

The choice of roofing material depends on the type of building and its operating conditions. It can be fixed with mechanical fasteners, glue, or fused-on varieties.

Rubemast

Rubemast is a material based on fiberglass, thick construction cardboard and bitumen. To improve its properties, plasticizers are introduced into the composition. The product is weldable, and the face layer is a mineral filling of fine or coarse fraction. Dust-sprayed rubemast is used as a lining for other roofing materials. If large elements are used for the front layer, the product is used for finishing.

Rubemast should not be used in a harsh climate. At a temperature of -15 degrees, it becomes brittle and can crack. The service life of the product does not exceed 15 years. The material is resistant to heating by the sun's rays and is silent.

Roofing material

Roofing material is a long-known material for soft roofing. The coating is light, does not lend itself to temperature extremes, and is resistant to moisture. However, the material is easy to damage, so you need to lay it carefully. Roofing material is a kind of surfaced roofing. You can put it at any time. The main condition is that the air temperature is not below zero.

Bituminous shingles

Bituminous shingles are a piece material of small sizes. The shape of the product can be different: hexagon, rectangle or rhombus. The advantage of the material lies in the breadth of the color palette and textures, the possibility of using it in the construction of complex hipped roofs. The coating is suitable for any style of building decoration. It reliably protects from atmospheric phenomena and decorates the house.

The shingles have a service life of about 20 years. The slope of the slope for its use should not be less than 10 degrees. Despite the type of roofing structure, this product does not lose its technical characteristics.

Uniflex

Uniflex is a weldable material containing bitumen and polymers. The basis of the product is fiberglass or polyester. It has a high tensile strength, resistant to mechanical damage, resistant to biological factors, direct sunlight. The flexibility of the web does not change even at negative temperatures.

Protective dressing increases the service life of the material. On the seamy side of the product, you can see an indicator that shows how well Uniflex is warmed up for styling. The canvas is used for the installation of the roof and for its repair. There are several types of product:

- Uniflex P. The variety is applicable for waterproofing a structure or as a bedding under another roofing material.There is a polymer film on the seamy side and front side, which prevents the product from sticking during transportation or storage.

- Uniflex K. It is suitable for covering the roof. The top layer consists of coarse shale. Thanks to this, the product is protected from the influence of ultraviolet radiation.

The characteristics of the material do not change at temperatures from -20 to +90 degrees. It is practically vapor-tight. There are about 3.5 kg of the product per 1 m², so it makes the structure heavier. If the installation technology is followed, the roof will last up to 25 years.

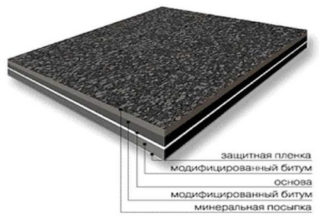

Technoelast

Technoelast is a modified build-up material used for roofing and waterproofing. It has high strength, suitable for flat and pitched roofs. The product performs well in harsh climatic conditions.

The basis of the canvas is fiberglass or polyester. Bitumen and polymers are applied to it, which improve the binding properties. A fine-grained or coarse-grained mineral dressing serves as a protective layer. The product is resistant to biological factors. Daily water absorption does not exceed 1%. The properties of the binders are reduced at temperatures below -35 degrees.

Soft roof device

Before installing a roof made of soft tiles, you need to consider the general structure of the structure. Layer order:

- rafter system;

- vapor barrier film and insulation;

- superdiffusion membrane;

- counter lattice made of bars;

- step crate, consisting of wooden boards;

- solid crate (for its manufacture, moisture-resistant plywood or OSB boards are used);

- lining material;

- soft roof.

This "pie" is intended for the construction of residential buildings. If you need to lay the material on an outbuilding, vapor barrier and insulation are optional.

Varieties of materials

The choice of a soft roof depends on its type and technical characteristics. The components from which the product is made are of great importance.

Rolled bitumen

The group of roll materials includes roofing material, uniflex, polymer membrane. You need to lay the product in strips. Bituminous types of canvases are fixed by fusion. It is necessary to heat the bottom layer of the product and press it against the prepared base. It is better to fix polymer membranes with glue. This group of materials is suitable for flat and pitched structures, the slope of which does not exceed 9 degrees.

Mastic or bulk roofs

There are roofing products that are applied to the substrate in a liquid form. After drying, a durable layer is formed that can withstand heavy loads. You can use one- or two-component formulations. A spatula or roller is used to apply them. There are options for a spray bottle. To make a reliable roof, you need to fill it in 3-4 layers.

Materials have the following advantages:

- absolute tightness due to the absence of joints;

- application on structures of any complexity;

- good adhesion to different types of substrates;

- resistance to atmospheric phenomena;

- wide temperature range for application: from -20 to +35 degrees.

Liquid formulations can be tinted. With proper installation and operation, such a roof will last more than 20 years.

Rolled polymer membranes

Membranes based on polymers are characterized by good resistance to external influences and high strength and protective qualities. There are such types of products:

- PVC. The material is made from a polyester mesh on which a polymer with a plasticizer is applied. The product is fixed by cold gluing with mastic. Hot air welding is used to join individual pieces.

- EPDM. A membrane of this type is also made from a polyester mesh, on which rubber (synthetic) is applied on both sides.To fix the canvas on the base, you need glue.

- TPO. The product is made of fiberglass and thermoplastic olefins.

The first option is the most common, since the PVC membrane is simultaneously a waterproofing agent and a roofing material.

Piece bitumen shingles

The shingles are made on the basis of fiberglass, which is impregnated with bitumen. Mineral chips of different fractions are applied to the front layer. The length of the fragments is about 1 m, and its width ranges from 30-45 cm.

Soft roof manufacturers

A feature of a soft roof is its ease of installation. However, when choosing, an important parameter is considered not only the technical characteristics, but also the manufacturer.

The following grades of material are in demand:

- Onduvilla. A modern product characterized by durability and visual appeal. The shingles have a cellulose base impregnated with bitumen. The finishing layer is mineral dressing. The roof is suitable for any climate. Due to its low weight, the load on the roof structure is negligible. The disadvantage of the material is its weak fracture strength.

- TechnoNIKOL Shinglas Classic. Domestic brand that meets international quality standards. The product is made from environmentally friendly raw materials. The advantage of the roof is the variety of colors, low weight, the possibility of fixing in a horizontal or vertical direction. Since the material contains oxidized bitumen, it is not recommended to use it in cold regions.

- Ruflex Runa. The product is used for covering roofs of any structure. It is resistant to temperature extremes, direct sunlight. The roof is not hazardous to human health or the environment. The material is characterized by an abundance of shades: terracotta, golden sand, blue, granite, ripe chestnut. The manufacturer offers a texture of scales, wave or brick.

Icopal products are distinguished by their good qualities. It is used to equip the most geometrically complex structures.

DIY styling instructions

The laying technology provides for surface preparation. If the base is a concrete screed, it is necessary to seal up cracks and chips with cement mortar, and then prime it. The rolled product is laid out on the roof for leveling, and then removed. It is better to carry out work at an air temperature of at least +5 degrees in dry weather.

Step by step process:

- Applying mastic and fixing the material. These manipulations are carried out almost simultaneously. The roofing material is heated and pressed against the base. Each new strip must be overlapped.

- Applying subsequent layers using the same technology. At the joints with adjacent surfaces, the material must be mounted with an overlap of at least 15 cm.

If the product is laid on a pitched roof, the installation pattern is slightly different:

- Laying the backing film on a continuous crate. Lay it from the bottom up with an overlap. A construction stapler and nails (at the bottom) are used for fixation.

- Installation of eaves.

- Installation of soft tiles. The first row is attached from below along the eaves. Elements are nailed. Each next row should close the caps. Cold bitumen mastic is used for additional fixation. It is applied to the degreased surface of the roofing material with a spatula.

- Installation of ridge elements. The elements should overlap the fasteners of the top row of tiles.

In places where chimneys, ventilation pipes, antennas come out, pass-through parts are installed - silicone seals. If the material is made with an adhesive base, no mastic is needed. Work is performed in protective clothing, glasses and gloves. A tarpaulin apron is required when using fire.

Repair and dismantling

The roof is not insured against mechanical damage from construction waste, strong wind, hail, branches.If the coating is badly damaged, it must be replaced.

Dismantle old material. To do this, use an ax or spatula. The base is cleaned, and the new canvas is laid. It is better to remove the old layer at a temperature that does not exceed 20 degrees. Work starts from the highest point. If the roof is badly damaged, you will have to disassemble it completely.

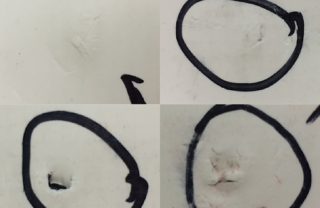

If the damage is localized, it can be repaired:

- Cracks and small holes are repaired with patches. A cruciform incision is made on the torn site. Mastic is poured under the old roof and a new fragment is laid. The edges of the canvas are wrapped, another patch is glued in their place.

- When the material is swollen, the bubble is punctured to eliminate air. The puncture site is filled with mastic.

- If the joints are parted, the edges must be turned off, treated with an adhesive, pressed to the base and smoothed.

After repair work, it is required to restore the upper protective layer by sprinkling the surface with sifted coarse river sand. Its remnants will eventually be washed away by rain or blown away by the wind.