The top covering protects the room from rain, snow and wind; its structure must be durable, lightweight, economical in construction and operation. The roofing device is performed in different versions, taking into account the purpose of the building, climatic conditions in the area, flooring material. The functionality is increased with the help of an additional insulating layer, insulation from steam and moisture.

- Roof types

- By construction type

- Depending on the material

- By the method of laying the roofing

- Roof structure and its main components

- Features of the roof device

- Soft roof

- From shingles

- From corrugated board

- Polycarbonate

- From bituminous corrugated sheets

- Seam roof

- Roof insulation at the stage of construction

- Correct installation of the roof

- The choice of roofing material

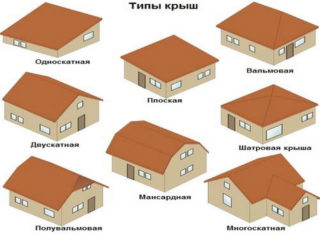

Roof types

The type of construction, material and method of laying the coating are chosen so that the layer withstands wind forces, snow load, and it is possible to clear it of precipitation.

In a general sense, surfaces are divided into two types:

- flat;

- pitched.

The first type is the simplest, the slope is 5 - 15 °, in the cold season such an angle does not provide self-cleaning. Flat roofs are used in the industrial sector and apartment buildings. To build a private mansion, a terrace, an attic, a pitched roof device is required. A frame roof with an attic will require additional funds, but the owner will receive a room for work or rest.

By construction type

Roofs are:

- Multi-stage and single-stage. The second type is distinguished by the absence of complex forms and is a budget alternative. Multistage ones have a complicated structure and lead to overconsumption of materials.

- Sloping and steep. The angle of inclination of the slope to the horizon shows the possibility of self-removal of the snow mass. On sloping planes, material consumption decreases, but its thickness increases. The steep roofing scheme increases the squaring, but allows for rare lathing.

- Hip and semi-hip. There are four slopes in the design, two of which are trapezoidal, the second two are triangular in shape. For such a structure, it is irrational to use metal tiles, corrugated board due to the large amount of waste.

Dome-shaped buildings and hipped roofs are rarely used due to the complexity of the construction site and the cost overrun of materials.

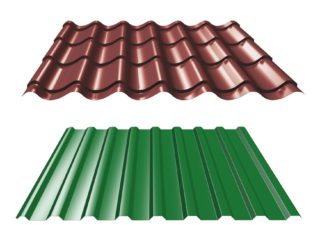

Depending on the material

There are hard and soft roofs. Tiles, metal sheets, profiled sheet, slate, wood are considered solid. The category of soft coatings includes roll materials, mastic coatings, individual bitumen piece elements.

Metal sheets are used smooth or profiled, with a galvanized and polymer layer. Wood coverings are suitable in areas with inexpensive local wood. Roofing material is used for the top layer in the roof structure and as a waterproofing layer.

By the method of laying the roofing

The choice of application method depends on the design, slope and type of material. The sheet material is mounted using a crate, which is nailed to the rafters. In the process, insulation and moisture insulation are installed.

Roll materials, for example, euroruberoid, roofing felt, glassine are glued on bituminous mastics, which are preliminarily applied to a solid base of chipboard sheets, moisture-resistant plywood.There are carpets with an adhesive layer applied from the bottom - they are heated before being pressed.

Mastic coatings are assembled in several layers, which are applied to the surface of concrete, wood, metal using distribution nozzles.

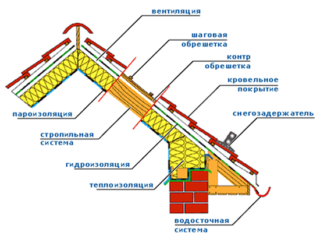

Roof structure and its main components

The roof structure for a private house consists of the elements:

- Mauerlat timber is placed along the perimeter of the wall fence;

- rafters are distinguished by type (diagonally, upright, folded);

- skate run;

- struts, racks, stretch marks, headstock;

- wind boards, filly.

A continuous surface is made along the rafters for a roll roofing device or a slatted sheathing.

Features of the roof device

It includes:

- vapor barrier film;

- waterproofing;

- insulation;

- roofing flooring.

Features of the coating device and the complexity of the work depend on the material and the steepness of the slopes.

Soft roof

Roll roofing is glued or fused to the base. Strips with a width of 1.5 - 2 m are used, which have a multilayer composition, a protective dressing in the form of mineral chips or a film. Soft materials are used when arranging a roof with a slight slope of up to 12 °. For heating, gas burners are used, in which there is a regulation of the flame force so as not to burn through the material.

The membrane type is assembled from weather-resistant PVC sheets. The sizes of the slabs are different, so there is a possibility of savings. Membrane coatings are considered expensive types, but such a roofing technology allows you to operate the roof for a long time without repair.

From shingles

Natural shingles are obtained by firing clay, the material lasts up to 120 years, subject to the technology of correct installation of the roof. The coating differs in quality characteristics, but it has a lot of weight, therefore it requires a reinforced supporting frame. The second disadvantage is the high cost of coverage.

Cement-sand tiles have become an analogue of natural ceramics, they are used for cladding private roofs. The material lasts up to 100 years and almost does not differ in appearance. The coating will also differ in a large mass, but the cost is inferior, so there are more buyers. Both species are placed on slopes with a slope of 20 - 60 °.

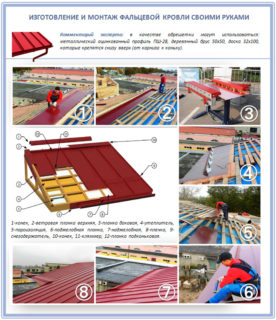

From corrugated board

At the base, galvanized sheets (0.5 - 1.0 mm) are used with a polymer coating on both sides. The strips are rolled on a forming equipment and a corrugated surface is obtained. The metal tile is a kind of profiled sheet, it is additionally stamped to shape it in the form of individual tile tiles.

The corrugated board is attached to the crate, nails are hammered into the crest of the wave. The sheets overlap each other by the width of the corrugation, and the length of the overlap is 7 - 10 mm. (depends on the slope). For insulated structures, an additional layer is placed - a counter-lattice, so that the layer does not come into contact with the waterproofing and condensation does not appear on it.

Polycarbonate

The material conducts light, so it is used to cover greenhouses and production hangars. In a private courtyard, greenhouses are covered with polycarbonate, gazebos canopies, and winter garden roofs are made. Its flexibility allows it to be used for arched structures.

The base is metal profiles, wooden bars. It is taken into account that polycarbonate expands when heated by about 4 mm by 1 p / m, therefore, they give the necessary freedom. Lightweight sheets are installed without lifters and cranes. Durable polycarbonate, thanks to the transverse bridges in the structure, does not transmit ultraviolet light. Fire-resistant material self-extinguishes in case of fire and does not emit harmful substances.

From bituminous corrugated sheets

Ondulin outwardly resembles asbestos slate, but differs from it in properties. Sheets are made on the basis of compressed cellulose pulp (3 mm), which is subsequently corrugated and impregnated with bitumen components. The composition includes antifreeze, fire-resistant additives, additives increase moisture resistance.

Bituminous sheets are often placed on a solid crate, and the rack frame is used only on steep roofs (45 - 60 °). The overlap in width is performed by one wave, which must be taken into account when calculating the material. Ondulin is lightweight and does not overload the load-bearing elements of the roof, so savings on wood are possible.

Seam roof

The coating is made of smooth metal sheets based on galvanized metal with or without a double-sided layer of polymer protection. The strips are fastened together by means of special protrusions along the edges of the product, which serve as locks and are called folds. There are single, double, recumbent, standing types of joints.

For crimping, machines are used that fix the joint. The coverage map is assembled in parts, which are placed on the ground, then raised to the installation position. For fastening to the crate, clamps (narrow metal strips) are used. If the slope of the slopes is less than 14 °, a solid base is made, and when installing a pitched roof of greater steepness, a standard crate is installed.

Roof insulation at the stage of construction

Moisture resistant types are used:

- Styrofoam;

- extruded polystyrene foam;

- foamed foam materials.

You can use mineral wool, natural types, for example, when installing a wooden roof. The materials are highly hydrophobic; when moistened, they lose their insulating properties. Therefore, during installation, an air gap is created in the flooring structure for circulation of flows and drying.

Correct installation of the roof

For the lathing, take dry bars (50 x 50 or 40 x 50), which are leveled in one plane so that there are no protrusions and depressions. They are fastened to the rafters with self-tapping screws, the joints are performed on the support in a checkerboard pattern. For fastening the metal coating, ondulin, roofing nails with a shock-absorbing pad are used. The instruction for the installation of the roof involves the production of a preliminary drawing with dimensions and a roof plan.

The choice of roofing material

The type of flooring is chosen depending on the preferences of the owner, his material capabilities and the technical characteristics of the coating. Take into account the effect of wind and the estimated height of snow cover in the area. Used in the calculation of construction reference books, where there are special tables. The documents indicate the pressure on the roof depending on the thickness of the sediment and provide the calculated indicators of precipitation and wind loads.

Each material has compressive and tensile strength indicators, which are also taken into account when choosing. Pay attention to durability, the possibility of maintenance and repair, the purpose of the building.

For a residential building, appearance, performance plays a role, and economical types of flooring are used on farm buildings.