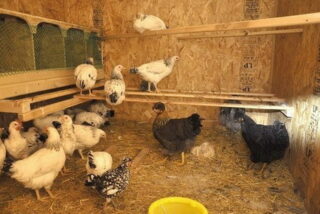

The productivity of poultry decreases sharply with the onset of cold weather and a decrease in the length of daylight hours. Warming the chicken coop allows you to partially solve the problem of deteriorating egg production and prevent massive infection of the bird with colds. The work is carried out on their own using improvised or purchased materials.

Chicken coop temperature

In order to prevent a sharp decrease or complete cessation of egg production, the average daily temperature in the hen house should be maintained at about + 15 ° C. The physiology of poultry is arranged in such a way that, when indicators are below normal, the body begins to use feed for the accumulation of fat and the formation of a feather, which serves to preserve heat. The hormonal background is rebuilt, productivity drops.

On short walks, the bird can easily withstand frost down to -20 ° C, but the risk of frostbite on the scallops and paws significantly increases.

Some owners use greenhouses for wintering chickens. This is permissible in the southern regions; heating is required in the Middle Strip. In any case, there is no need to wait for eggs in such conditions.

Modern breeds and crosses are carried all year round, provided the necessary microclimate is provided. To create it, you need a well-insulated and heated chicken coop.

Warming the chicken coop for the winter

Heat escapes from any building, through the floor, walls, ceiling and doors, so attention is paid to each element of the structure. They use different materials and methods.

Floor

According to the measurements carried out, up to 25% of the thermal energy goes through the soil. There are several construction methods to reduce losses:

- arrangement of a concrete floor with a expanded clay pillow under it;

- manufacturing of wooden flooring with or without insulation.

A simple and affordable method that does not require significant costs is the bedding of natural or artificial materials, it can be used on any floor.

Litter is divided into regular and deep.

In the first case, shavings, sawdust, wood chips, moss peat, sunflower seed husk are used. The thickness of the bookmark is no more than 10 cm. The principle of operation is based on low thermal conductivity, which is why the energy is stored inside the room.

When using sawdust and shavings, it is necessary to ensure the constant availability of feed. Otherwise, the chickens peck on the litter, and this is dangerous by blockage of the goiter and the death of the bird.

As it gets wet and dirty, the litter must be turned over, and, if necessary, replaced. The frequency of replacement depends on the climate and the number of chickens. On average, 2-3 shifts will be needed during the winter season.

Deep bedding, in addition to thermal insulation, heats the room themselves. For the arrangement, plant residues, straw, dry grass, crushed remains of corn cobs are used.

In the thickness of the litter, the processes of bacterial decomposition of organic matter, including droppings, begin, accompanied by the release of heat. Fermentation promotes heating of the substrate, evaporation of moisture, the litter remains dry and does not require replacement during the entire winter period.

Special bacterial additives have appeared on the market, starting the decomposition.

Ready-made fermented beddings are also expensive, requiring replacement after 2-3 years, but using them in a home chicken coop is impractical if the goal is to save money.

Some poultry farmers make heated floors in this case, it is permissible to fill the floor with sand for the winter, which will have to be changed once or twice a season.

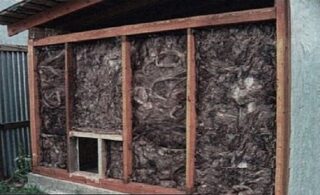

Walls

The large surface area contributes to strong heat transfer, so they must be carefully insulated. Sheathing is carried out both inside and outside. Choose a suitable material.

Outside, insulation is carried out using the methods of wet and ventilated facades.

Wet facade - mineral wool, polystyrene or polystyrene foam reinforced on the wall are covered with a layer of plaster.

As a heat insulator, mineral wool with a density of 70 kg / m3, polystyrene (expanded polystyrene foam) of the brand not less than PSB-25, with a density of 17 kg / m3 or any type of foam (extrusive polystyrene foam) is used. The sheets are fixed on a special adhesive or with dowels with wide caps.

Plastering is carried out in two layers:

- facade adhesive for expanded polystyrene applied simultaneously with the painting net;

- the main layer of facade plaster.

Ventilated facade - wall insulation with one of the above materials, which is closed with a finishing finish. You can sheathe the chicken coop outside with siding, metal profiles or OSB plates.

For internal cladding, a frame made of wooden blocks or galvanized profiles is attached to the walls. Between the crate, they lay insulation for the hen house, which is covered with OSB plates, plywood, boards, clapboard. It is impossible to leave open polystyrene, mineral wool or penoplex, the chickens will peck them.

Ceiling and roof

The ceiling is insulated from the inside or from the side of the attic.

The first option involves fixing sheets to the ceiling and covering it with clapboard or other similar materials.

If they act from the side of the attic, then a layer of insulation is laid on the ceiling, covered with a waterproofing film.

It is undesirable to insulate the ceiling from the side of the attic with mineral wool, which gradually cakes and loses its useful properties. It is better to use polystyrene grade PSB-25 or penoplex, on which you can walk carefully.

A simple way to insulate the ceiling from the attic side is a poured layer of sawdust or expanded clay. This is done if the overlap can withstand a large mass of building materials.

Sawdust must be impregnated with an antiseptic and an anti-combustion composition.

Windows and doors

It is necessary to insulate the door leaf, as well as the places where the frames fit the walls. If possible, a second window frame is made and inserted for the winter period.

Joints and abutments are sealed with polyurethane foam or materials at hand: cloth, foam rubber, cotton wool, felt strips. They use the old way of pasting the windows with paper tape.

The doors from the outside are upholstered with foam rubber and foil. From the inside, you can additionally strengthen roofing material or other suitable material that prevents drafts, if the door is planked.

Rollers of various materials are nailed along the perimeter of the canvas, ensuring a tight fit of the door to the jambs.

The manhole is made to a minimum size to reduce heat loss. The perimeter is insulated in the same way as the main door, excluding drafts.

Heating

The heat generated by birds and deep bedding is not always sufficient to maintain the required temperature. In such cases, artificial heating is used constantly or on particularly cold days and nights.

Which type of heating device to choose depends on local conditions, fuel availability, type of building.

Electric heating

Using electricity can be justified:

- in rural areas, where the tariff is significantly lower than urban;

- for wooden buildings, where it is dangerous to use stove heating.

Advantages of the method: ease of installation and maintenance - just bring an electric cable to the shed and hang the heater on the wall. The temperature is regulated by built-in, external thermostats or timers set for the desired period.

According to the principle of operation, any types of electric heaters are emitters of infrared waves, however, their device may be different.

Oil radiators heat up to temperatures of about 60–70 ° C, do not burn oxygen, and are easy to transport from place to place. Often they are equipped with an additional heater with a fan to quickly warm up the room. The regulator works and turns off the device, measuring the temperature of the oil in the housing, and not the air in the room. Because of this, it is impossible to accurately establish and regulate the microclimate parameters in the chicken coop.

Convectors allow you to quickly warm up the room due to the accelerated mixing of air. Cold streams, passing near the body, heat up and rise to the ceiling, displacing a new portion of cool air to the floor, the process is repeated. For the chicken coop, a wall version is chosen, since chickens will settle on the floor types, contaminate the surface and periodically overturn the devices. Built-in convectors can be built into insulated walls.

Infrared heaters emit waves into the space, but they do not heat the air by themselves. The waves heat up the surrounding objects, the floor and walls, which give off heat to the space.

A separate type is infrared lamps, which consume about 10% for lighting and about 90% for heating the area where they are located.

The most common halogen models of IR heaters, where a special lamp is the working element.

Ceiling ceramic infrared heaters are best suited for chicken coops, since they are not accessible to birds, but at the same time they can be placed over any place where heat is needed, for example, over a perch.

Fan heaters quickly warm up the room, but are unsafe to use. Modern models are equipped with protection - when overturning, the contact opens and the heating stops. Wall-mounted models are poorly suited for dusty rooms - dirt, dust, cobwebs quickly accumulate on moving parts, devices have to be often disassembled and cleaned.

Monolithic heaters are equipped with bodies made of ceramics, sintered quartz sand or polymers inside which a nichrome thread is pressed. When connected, the wire heats up, giving off heat to the body, which heats the air. The devices are the most durable, fireproof, safe, since they do not heat up above 40–45оС. At the same time, you will need to purchase 2-3 devices for the chicken coop, since the maximum power of the heaters rarely exceeds 250-300 watts.

Micathermic heaters have been on the market for about 10 years, but they are rarely used for chicken coops - the mesh with microcells, which is the basis of the device, quickly becomes clogged with dust and productivity decreases.

Which model to choose

When choosing the option of an electric heater, it is taken into account that the efficiency of any device is close to 95%, since all electricity is directly converted into heat.

The main conditions for selection: the required power, convenience and safety of operation in a particular chicken coop.

The degree of insulation of building structures, the required heating zones, and the parameters of the electric cable are taken into account.

Water and gas heating

In everyday practice, for small chicken coops, it is unprofitable to equip water circuits or bring a gas pipe to the chicken coop.

However, in order to heat the chicken coop, you can equip a water circuit with your own hands from improvised materials or materials left over from the construction of the house. For the manufacture of a gravity system, pipes with a diameter of 70 mm or more are used.The water is heated from the electric heating element and rises up the pipes, then the flow falls down along the inclined sections, giving off energy. On the return flow, the coolant returns to the heater, the process is repeated.

On especially frosty days, a gas infrared burner is used for heating, which is powered from a bottle of liquefied propane.

Attention! In order to avoid fires, it is forbidden to leave the burner unattended - a fall will cause an instant ignition of the bedding and a fire in the entire chicken coop.

Stove heating

Wood and coal stoves and diesel heaters with open flames are the most dangerous in terms of the possibility of fires.

It is highly discouraged to install such devices in wooden sheds, as well as near a bed made of combustible materials. In addition, the devices need constant supervision. Fuel in small stoves quickly burns out, and there is not enough heat for the whole night.

Comparison of heating methods

Each of the methods is acceptable and most suitable for specific conditions of use, has advantages and disadvantages.

Comparison table.

| Heating type | Benefits | disadvantages |

| Electrical |

|

|

| Stove |

|

|

| Diesel stoves |

|

|

By insulating the chicken coop and organizing its proper heating, a good owner minimizes the loss of egg production. It is important to choose the right way to protect the bird from the cold, make the most of the available, and often waste materials.