Garage painting is of great aesthetic and protective importance. The correct selection of material will allow you to create comfort and coziness in the room, make it beautiful and attractive from the outside. The garage is often used to store flammable materials, so it is necessary to choose the right color, type of paint and the way it is applied to various surfaces.

Types of paints for painting a garage

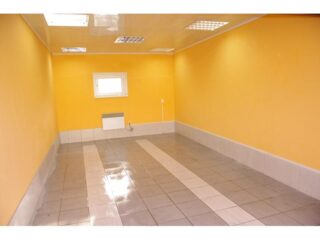

Before painting the walls in the garage, you should take into account the specifics of this structure. It has a small size, poor lighting due to the absence of large windows, increased pollution and fire hazard. In the overwhelming majority of cases, buildings are not heated or are periodically warmed up by household appliances.

Garage paint requirements:

- immunity to temperature extremes, condensation, freezing and defrosting cycles;

- incombustibility, including in contact with an open flame;

- resistance to moisture, fuel, solvents and other technical fluids associated with the operation of the car;

- environmental safety necessary for a long stay in the building of people;

- ease of washing from oils, dirt, grease stains;

- pleasant appearance to create a comfortable environment and a sense of coziness.

To paint your garage, you can use these types of paint:

- Oil. A budget option that is well suited for interior and exterior work. The coating is easily applied to the surface, forms a dense layer resistant to moisture. It should be borne in mind that the material fades over time, and with temperature drops it exfoliates from the base.

- Acrylic. Inexpensive, but better quality composition. Suitable for all natural and synthetic surfaces. It has a bright and rich color that retains its hue for a long time. Resistant to chemicals and UV light. The coating is prone to abrasion and gradual color change.

- Polyurethane. The products are expensive, but the investment in every square meter is worth it. After drying, the enamel forms a coating resistant to all external factors, characterized by durability, strength and presentability.

- Vinyl. The composition is waterproof, dense and durable. However, it can only be used internally, as the sun and wind lead to its destruction.

- Alkyd. Wear-resistant, versatile, well suited for painting all substrates from the inside and outside of the building. Compositions with a matte and glossy surface are on sale.

In all cases, you need to choose a paint that best suits the operating conditions of a particular room: such as the presence or absence of heating, humidity level, smoke and the risk of fire.

Tools for work

To paint the walls in the garage with high quality, you need to carefully prepare for this process.

The work can be done with the following tools:

- Paint roller. Used in conjunction with a tray into which a certain amount of liquid is poured. The device allows you to quickly cover large areas by applying the solution in wide strips. For textured surfaces, choose rollers with long and medium pile, and for smooth surfaces - with short or foam. Texture rollers can be used to create an original surface. The only disadvantage of the device is that it is impossible for them to process hard-to-reach places in frames, corners and behind pipes.

- Paint brushes. The devices are functional, depending on their size, they can paint large areas and small objects with a complex surface. Before use, it is recommended to fluff up the bristles, pull loose hairs out of them with your hands, shake off dust.

- Spray guns. The purchase of such a device allows you to process the entire structure quickly and efficiently. When the liquid is blown out, a dense torch is formed, which ensures the filling of the smallest pores, cracks and holes. Electrical devices are easier to use, as they operate on the mains or battery. Pneumatic models require connection to the compressor and fine adjustments.

Having decided on the choice of the type of paint and tools, you should proceed to the next stage - design development.

Color Tips

Choosing what color to paint the walls in the garage, it is not necessary to copy the ideas of the neighbors, but this method can lead to interesting thoughts and solutions. The standards in this direction are only technical, so the choice of color scheme and shade is a creative and purely personal matter.

It is recommended to use the advice of experts:

- A light background expands the space, with it the room will appear taller and wider. Reflective properties will make it much lighter and more fun. The effect is well complemented by silverfish mixed in a solution.

- The gray color is practical, dirt is practically not visible on it, but it acts depressingly, provoking despondency and bad mood. It shouldn't even be used for floors, let alone walls.

- You should not give up options that are not associated with garage decoration. Red and yellow help to increase productivity, green is calming, and blue improves focus and concentration. Light green and blue are neutral, but help to relax.

- An excellent effect is given by drawing the seams on a brick wall. The stones themselves can be painted in bright, cheerful colors.

When choosing a color scheme, you should not focus on variegation or excessive brightness. It has an annoying effect on vision and psyche.

Preparatory work

Garage paint will adhere well to the surface if it is pre-treated with the appropriate coating. The elements of the garage are made of different materials and each of them has its own preparation technology.

Metal fragments and planes take the longest to prepare, as they differ in hardness and strength. If the processing area is large, it is advisable to use the means of mechanization. These can be angle grinders, belt grinders and vibratory grinders with replaceable abrasive nozzles.

Sequencing:

- Wires, bolts, screws are removed from the surfaces. The protruding fragments are cut off if they are not needed in the future.

- The iron is cleaned of rust. You can skip polishing, as the paint will smooth out all the irregularities.

- A primer is applied. The liquid prevents corrosion and improves material adhesion.

With a tree, it is a little easier, but a little longer. Work algorithm:

- Remove old paint, varnish or other previously used cladding.

- Identify resin-producing spots. Heat it with a hairdryer and remove it with a rag.

- Sand and polish the surface.

- Remove dust from wood using a vacuum cleaner and rags.

- First apply an antiseptic, and after it dries, a fire retardant and impregnation.

Further processing can be carried out after complete drying of the material.

Concrete and brick have a porous structure that absorbs moisture well.

You need to prepare them for coloring like this:

- Clear the seams on the masonry, grind off strongly protruding fragments.

- If there are significant irregularities, plaster the problem areas.

- Degrease surfaces with acetone or its analogs.

- Treat materials with a deep penetration primer.

In all cases, painting should be carried out at a positive temperature, after the condensate has completely dried out and there are no drafts.

Dyeing process

Each part of the garage has its own characteristics and requires a separate approach in terms of the choice of material and technology for its application.

A gate is a structure that is exposed to almost all existing destructive factors. Based on this, the most stable paint in all respects should be used to paint them. An excellent solution is a hammer mortar, which protects the iron from corrosion. To achieve the best effect, apply at least two layers with a change in direction.

Typically, a garage floor is made of concrete or boardwalk. The surface is subject to abrasion, therefore, the most wear-resistant composition is selected for it. For concrete, epoxy, acrylic and polyurethane paints are suitable, you can use liquid glass or bulk polymer. It is better to cover wood with varnishes with natural or synthetic resins and solvents. They will protect the floor from chemicals and high humidity. A good effect is given by epoxy and acrylic compounds, characterized by high strength.

Oils and waxes help improve adhesion and extend the life of the coating.

After casting, concrete walls have many characteristic irregularities, which are inappropriate to grind and putty. It is better to cover the surfaces with plaster, which will perfectly level the surface. Already for this finish, any waterproof paint can be applied after priming. If you don't like this option, the concrete is polished and then treated with a special primer. Penetrating deep into the material, the liquid strengthens and colors, creates depth and color saturation. Subsequently, such a surface can be coated with any paint, as it is an excellent base.

Due to the temperature difference, metal walls are constantly exposed to condensation. For their coating, formulations that are resistant to dampness, moisture and freezing are selected. They should be applied from top to bottom with vertical strokes to avoid sagging and dripping. Depending on the climatic conditions, 2-3 layers are made.

Cinder block garages are characterized by low thermal conductivity, frost and condensation rarely form in them. There are no high requirements for their interior decoration. The main thing is to thoroughly prime the blocks. Given their textured surface, the composition is best applied with a spray gun.

It is better to work on plaster with vinyl and polyurethane mortars. They are distinguished by good tightness, elasticity and presentable appearance. Here, too, a high-quality surface primer is required.

It is advisable to treat the ceiling in the garage with silicone or silicate facade paint. But if desired, it is possible to apply acrylic or oil compositions.

Painted surface care

The process of maintenance of painted surfaces involves regular cleaning of dust, dirt and traces of fuels and lubricants.This procedure should be performed as needed, but at least once a month. If you miss the moment, dirt will bite into the finish and leave a permanent stain on it.

Care must be taken with solvents to avoid rubbing off previously applied coating.

If chips and scratches appear, they are putty, primed and painted over with a composition similar in shade.