Aerated concrete blocks are wall building materials that are popular in the construction of low-rise residential buildings. They are easy to handle and provide good thermal insulation. However, the interior decoration of such walls has some peculiarities. Since the blocks are made of aerated concrete, they are characterized by high porosity. This quality makes us take a responsible approach to the choice of finishes.

Characteristics of aerated concrete

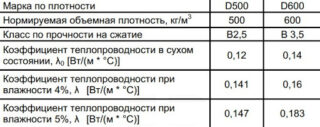

Aerated concrete contains aluminum powder, cement, quartz granules, lime, water. All components are thoroughly mixed and processed in an autoclave. After that, foaming components are found in the composition of the raw material, due to which the material receives a cellular structure. The finished product has the following characteristics:

- element mass: up to 30 kg (1 block replaces 22 bricks, the mass of which is 100 kg);

- level of thermal conductivity in a dry state: 0.12 W / m 0C;

- resistance to ignition and combustion: the material is able to withstand the unilateral effect of fire for 4-7 hours, and buildings erected from aerated concrete are classified as fire safety categories 1 and 2;

- tolerance to negative temperatures: at least 25 freeze-thaw cycles;

- strength level: the limit is 500 kg / cubic meter;

- background radiation: 9-11 mcr / h.

Since the material contains only natural ingredients, it is environmentally friendly. During operation, there is no release of toxic substances.

Advantages and disadvantages of aerated concrete

The aerated concrete block is popular due to the following advantages:

- ease of processing: it can be drilled, sawed, cut, channeled;

- low cost of the production process, so the price of the material is available to any buyer;

- environmental Safety;

- no need for additional insulation (depending on the climatic zone);

- high speed of installation;

- precise geometric shape, thanks to which the elements can be fixed with glue, which eliminates the appearance of cold bridges;

- reducing the cost of heating the house by 25-30%;

- good sound insulation properties compared to brick structures;

- the ability to store heat (both internally and externally)

- the ability to erect buildings of any configuration and shape: blocks allow you to build arches, breaks.

The material has such disadvantages:

- for the construction of load-bearing walls, D600 grade material is required, the thermal insulation properties of which are reduced;

- high hygroscopicity: since the blocks absorb moisture, they must be covered with finishing materials;

- the appearance of cracks due to deformation loads that appear during the shrinkage of the building (a solid monolithic foundation is required to minimize them).

If several types of aerated concrete blocks have to be used in construction, its cost increases.

Types of materials and finishing methods

The correct choice of design options for walls made of aerated concrete provides an optimal indoor climate, increases the duration of the building's operation.Cladding methods are frame and frameless. From materials you can use wallpaper, plaster, wood panels, plastic products, tiles.

Drywall

To fix the sheets of GVL, it is required to equip the lathing made of wood or aluminum profile. Before finishing the base, it is primed with a special compound with vapor barrier properties. To fix the frame, use dowels designed for the gas block. A ventilation gap of 5 cm must be left between the cladding and the wall. If there is a need for additional insulation of the building, the space between the sheets and the base is filled with stone wool, fiberglass.

Plasterboard improves the aesthetic properties of the interior, creates a flat and smooth base, provides additional vapor barrier properties, allows you to remove all communications in the structure.

The sheets must be properly fixed to the porous material. Due to the need to build a frame, the useful area of the room is reduced.

Plaster

When using a plaster mixture, the base requires treatment with a waterproofing primer. If the mortar has vapor-permeable properties, the finishing layer must be of the same quality. Since the blocks have high porosity, it is necessary to choose a plaster with high adhesion properties. A mixture based on cement and sand, lime, gypsum is best suited for work. The material can be used only in rooms in which there is a normal level of humidity.

This material is able to improve the heat and sound insulation properties of walls. The base becomes more solid. However, improper preparation of the solution or non-compliance with the technology of its application leads to rapid peeling, cracking of the layer. In addition, there is a risk of mold and mildew accumulation on the surface of aerated concrete.

Wood

Wood is an environmentally friendly material that creates an optimal microclimate in the house. The interior turns out to be cozy and looks rich. Due to the similarity of technical characteristics, wooden finishes go well with aerated concrete. Both materials have a porous structure and low thermal conductivity. Before using the lining or panels, they are treated with antiseptic, antifungal, fire-protective solutions. Indoors, you can use pine and spruce finishes.

Ceramic tile

For wall cladding inside rooms with high humidity, you can use ceramic tiles. To prevent the development of fungus and mold on the surface of the base, when using such a material, the arrangement of high-quality supply and exhaust ventilation is required. To fix the tiles on the wall, use a special glue designed for aerated concrete.

Wallpaper

Wallpaper is an inexpensive finish. Suitable for work are vinyl and ordinary materials, as well as canvases from natural fibers. You need to glue the wallpaper on a flat surface. For this, the walls are plastered with a solution of cement and sand, and then primed with moisture-resistant glue.

Painting the walls

For finishing aerated blocks, water-based paint is more suitable. It is inexpensive and easy to apply. In this case, the base requires preliminary preparation: it must be cleaned, leveled, and sanded. Water-based formulations can be tinted. The next layer is applied without waiting for the previous one to dry completely.

When using plastic panels, no preliminary leveling of the wall is required. Elements are attached to the crate. The material is cheap and easy to assemble. However, he is afraid of temperature extremes.

Required tools and materials

Depending on the chosen finish, the following devices will be required:

- puncher and drill;

- screwdriver;

- marker, square, measuring tape;

- building level;

- grinder, scissors for metal, hacksaw for cutting wood;

- trowel, spatulas of different sizes (if necessary, plastering);

- a hammer;

- aerated concrete planer, grater (for leveling the base);

- wall chaser.

It is necessary to prepare wooden or metal elements for the formation of the frame, plaster, primer, screws, dowels. For painting, you will need a roller, a paint brush, and a solution tray.

The order of work

For the correct decoration of a house made of aerated concrete, the following step-by-step instructions are followed inside:

- Preparation of the base. It is cleaned of dirt, stains, solution residues. Large cracks need to be repaired.

- Surface priming. The solution is applied with a paint brush in several layers.

- Reinforcement of the base with fiberglass mesh.

- Plastering. The mixture must be mixed with water in the proportion indicated on the package. If tiles are chosen for finishing, one preparatory layer of plaster is sufficient. For painting and wallpaper, it is better to use a starting and finishing mixture.

- Wall painting or wallpapering.

If drywall or plastic is used for decoration, a crate is pre-built. The vertical elements are fixed at a distance of 40-50 cm. They can be reinforced with horizontal bridges. After fixing the structure, hydro, heat and vapor insulation is attached to the base. Drywall (plastic) is screwed (nailed with a stapler) to the crate. A deformation gap of 2-3 mm is left between the sheets of gypsum fiber board.

Gas blocks have many positive qualities, but to increase their service life, they need to be protected from moisture and other negative factors.