A special device in the form of a chimney head on the roof is called a roof ventilation outlet. Conclusions are divided into types that are used for different slopes, attic and flat structures. The devices include component parts in the form of adapters and bushings; devices are selected depending on the type of roof and the diameter of the pipes.

- Materials for the manufacture of a ventilation outlet on the roof

- Plastic products

- Galvanized steel

- Requirements for ventilation structures

- Number of connections

- Inner surface

- Corrosion resistance

- Choosing a place for a ventilation outlet on the roof

- DIY installation

- Stages of installation on the example of metal roofing

- Additional devices

- Aerators

- Droppers

- Deflectors

- Visors

Materials for the manufacture of a ventilation outlet on the roof

The pipe is under the influence of unfavorable outdoor conditions, therefore, certain requirements are imposed on the material. The device should not lose its characteristics in heat, frost, and ultraviolet radiation.

The material of the chimney for the roof must meet the requirements:

- beautiful view;

- color match with the color of the roofing;

- corrosion resistance and moisture resistance.

Several materials are used to organize the exit. Plastic and galvanized are popular.

Plastic products

The material is produced on the basis of natural or synthetic polymer compounds. Roof ventilation elements are produced by the formation method, in which multiple joints and gaps are excluded.

Lightweight material (density 0.85 - 1.8 g / cm3) does not load the roof structure. The products are easily installed in the installation position. Plastic resists the action of acids and alkalis, which are in the free state in the atmosphere. The composition includes plasticizers to control thermal expansion and dyes, so colored PVC does not fade in the sun.

Galvanized steel

Such ventilation exits to the roof with a small wall thickness are durable and do not deform under the influence of wind or accidental mechanical stress. The zinc coating is made on both sides of the metal profile, the layer is evenly distributed.

Products differ in qualities:

- duration of work in open conditions;

- wear resistance;

- environmental Safety.

Devices for organizing galvanized exits are budgetary in comparison with stainless steel. The cost of products depends on the thickness of the base and the covering layer, as well as the variety: roof ventilation for metal tiles, ondulin or folded roofs.

Requirements for ventilation structures

Roof exits should, together with the ventilation system, maintain the temperature regime in the interior and under the roof, remove household vapors.

Products are produced in accordance with the requirements:

- the presence of mounting seals;

- the ability to adjust along the vertical axis;

- units compatible with ventilation pipes;

- minimum number of joints.

Devices should not allow moisture to pass through, corrode, inside you need a flat surface without roughness, protrusions and bends.

Number of connections

Engineering ventilation passages through a roof made of metal, profiled sheet, bitumen should be carried out with a vertical axis holding and have few joints.Experts do not recommend combining several ventilation lines into one outlet to reduce the number of bends.

For each hood in the bathroom, kitchen, living rooms, a separate outlet is made to the roof surface. Select products made by pressing, without joints along the length, in order to ensure the smooth movement of air flows.

Inner surface

The inner surface of PVC and galvanized metal pipes is smooth (roughness coefficient at the level of 0.0005 mm), so the air does not encounter resistance when moving along the channel, the throughput increases.

If there are irregularities in the area, over time, fats are deposited on the walls, a coating of other volatile substances appears. A bumpy surface increases the noise level when air passes through.

Corrosion resistance

The problem of corrosion is the formation of a loose substance (rust) on products under the influence of water. As a result, the tightness of the walls of the exhaust system to the roof through the metal tile is broken due to the formation of holes and through holes.

Plastic and galvanized products are moisture resistant, so the materials do not corrode during the entire period of operation.

Choosing a place for a ventilation outlet on the roof

More often, a ventilation outlet to the roof for a soft roof, corrugated roofing, steel is made in the area of the ridge. This is due to the fact that a minimum height above the roof level is required, the element will be resistant to wind and prefabricated devices can be mounted.

If the chimney comes out nearby, the ventilation outlet is placed at the level of the ridge, but made slightly below the chimney header. The choice of the exit location is regulated by the norms of SP7.13130 - 2009 and SNiP 41.01 - 2003.

DIY installation

Ventilation outlets are mounted simultaneously with the device of the roofing carpet or built into the finished roof. The first method is preferable, since there is no need to remove the covering, redo the elements of the lathing. The lead-through flange is attached to the base using synthetic mastic and nails, and the hole around the element is waterproofed.

The construction of the base requires reinforcement at the exit point using the method of solid lathing or the installation of additional bars. Steel lining or special aprons are installed after the installation of ondulin, soft tiles, profiled metal.

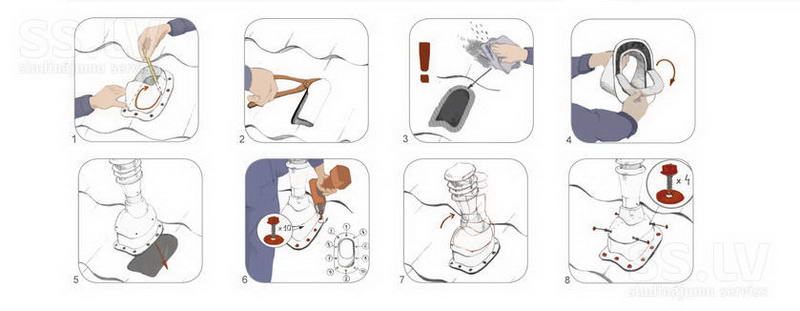

Stages of installation on the example of metal roofing

Initially, the installation site is marked out according to a special template, which is sold along with the output so that there is no crate under the sheets, or it will have to be dismantled.

Work order:

- make a hole for the roof ventilation device from metal tiles in the coating, waterproofing, insulation with a grinder (circle 115 mm) or scissors for cutting metal;

- arrange additional bars for fixing the outlet in the structure of the lattice;

- a sealing element is fixed around the hole on the mastic;

- a sealant is applied to the lower part of the pass-through fold and the element is fixed to the base with self-tapping screws;

- in the space of the attic, the ventilation outlet is joined to the pipe, which is rigidly fixed in the required position with clamps or brackets.

The outlet on the roof is treated with special elements, the surrounding gap is closed with material in color to match the roof.

Additional devices

It can be:

- aerators;

- droppers;

- deflectors;

- visors.

Additional devices increase the performance of the ventilation system, increasing the traction inside the line. Structural devices protect the inner space of the outlet element from water, snow, debris.

Aerators

The devices accelerate the air currents under the roof carpet and insulation when the natural draft is insufficient. Aerators are flat plates designed to dilute the air density, so that the streams are removed from the under-roof gap.

The size of the elements differs depending on the type of covering, as well as their number for different roofing materials. Plates are placed in increments of no more than 12 meters in high areas of the slopes. In roofs with a slope of 15 - 45 °, special passages are provided - ridge vents, aerators are mounted in such recesses.

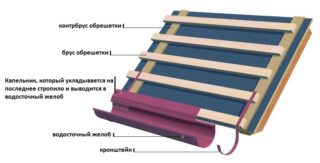

Droppers

The device is a ventilation hood on the roof, which serves to remove melt and rain moisture from the inner space of the exhaust pipe. The cap of the device is made with an inclination, the bottom is the drip itself, and the sides are provided with a convex border that protrudes at least 10 cm beyond the dimensions of the passage.

The ventilation ducts are completely covered with a cap, and holes covered with a grating are provided on the pipe walls. The protection cells are not made small so that they do not get clogged. Drippers additionally protect against condensation and reduce the noise of the system if there are fans there.

Deflectors

They are a ventilation fungus on the roof, which is placed on the head of the pipe to reduce the pressure in the area around and increase traction. The device generates and flows of air and directs them in the right direction.

Deflector functions:

- does not allow the wind to enter the inner space of the pipe;

- excludes the appearance of reverse (overturning) thrust;

- protects from precipitation, debris, birds.

There are models with an extended head - a diffuser, they produce devices in the form of a cylindrical mushroom on the roof for ventilation, a spherical turbo deflector, a dynamic device.

Visors

The cornice is mounted on the outlet of the ventilation outlet in order to prevent the destruction of the inner walls from the action of atmospheric precipitation.

Various materials are used for manufacturing, steel, reinforced with PVC. The elements are placed on the ventilation ducts of a soft and hard roof, but they are made to a minimum thickness so as not to burden the bearing rafters.

For attachment to the pipe, special racks and brackets are used that are attached to the outer walls of the collector. Visors are made single and gable in the form of a pyramid, dome, umbrella.