Wood has always been popular in construction due to its qualities. There are several types of timber for building a house, differing in consumer properties and price. Especially carefully select material for houses in which you have to live year-round. The durability of the building and the comfort of the owners depend on the right choice.

Requirements for the properties of construction timber

There are several requirements for building materials:

- affordability of the price;

- durability of use;

- heat-shielding properties;

- reducing the level of extraneous noise;

- environmental friendliness;

- ease of use.

When self-erecting, as well as for construction crews, the manufacturability of materials (ease of work), minimal labor costs and the speed of construction are important.

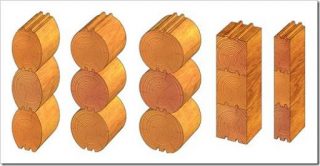

The industry supplies the following types of timber for building a house:

- edged (sawn) solid;

- profiled one-piece;

- glued profiled:

- insulated multilayer.

Materials differ in manufacturing technology, construction features and some consumer properties.

Varieties of timber

For each of the types, mainly coniferous wood is used: pine, spruce or larch, less often cedar. Deciduous material is much more expensive or less resistant to external influences.

Trimmed

The manufacturing technology of the material is simple - a solid log is cut from four sides in such a way that a bar with a section of 15x15 or 15x20 cm is obtained with a length of 3000, less often 6000 mm.

Drying of workpieces is not carried out, the edges are not polished.

Low cost, environmental friendliness and widespread availability are the positive properties of the material.

There are many disadvantages of sawn timber:

- Walls require a finishing decorative finish, since the appearance of log cabins from a bar is unattractive.

- Deviations from linear dimensions force the fitting of individual parts. Otherwise, there will be a pronounced skew in the height of the walls and their flat surface.

- The material must be properly dried at home before laying, as it can be sold with any degree of moisture.

- The joints will require careful insulation and annual prophylaxis due to drying out of the wood.

- Gradual cracking of the timber under the influence of weather conditions.

- Extended terms until the house is ready for decoration and living - about six months should pass before the installation of windows, doors and interior decoration begins. Otherwise, due to shrinkage, the frames may twist, and the door sashes will jam.

- Flammability. The walls must be impregnated with chemical compounds - fire retardants, which affects environmental friendliness and, if the composition is incorrectly selected, can be dangerous to the health of the owners.

It is better not to use ordinary edged timber for building a house. To eliminate material shortcomings, expensive finishing and constant maintenance will be required, which entails monetary costs.

Profiled one-piece

For the production of profiled beams, only prepared material is used.

The logs are freed from the bark and dried. There are 2 ways to get rid of moisture:

- natural drying for 4–5 months under a canopy, protected from sunlight;

- in a special drying chamber.

The processing begins when the moisture content of the wood drops to 22%.

The logs are cut from all sides, giving a rectangular shape in the cut. Then, profile samples are made along the upper and lower edges. During the construction of walls, the timber is connected with a thorn-groove lock.

One or more samples are taken.

The design greatly reduces the likelihood of through holes between parts.

Manufacturers work according to the Specifications. In most cases, the basic requirements for finished products are as follows:

- knots with a diameter of no more than 20 mm in any quantity are allowed, with a size from 20 to 50 mm no more than 2 pcs. per running meter;

- rotten, tobacco knots are not allowed;

- cracks from 2 to 4 mm up to 500 mm long, no more than 1 pc. 1 m / p .;

- wane, rot, blue wood and unevenness are prohibited;

- sawing logs radial, tangential and semi-radial;

- deviation of geometric dimensions in any section and along the length of no more than 3 mm.

Solid timber can lose shape over time or crack under the influence of climatic factors, which is a disadvantage. At the same time, the thickness of the walls (maximum 20 cm) is not sufficient for year-round living. The house is insulated and finished, which significantly reduces the likelihood of damage to the wood.

The advantage of profiled timber over sawn timber is ease of installation, reduction of labor costs and materials for insulation of joints. The groove connection facilitates precise installation, the walls are flat.

Profiled glued

Such a bar is made by gluing lamellas. For production, industrial adhesives are used, and the joining process itself takes place under high pressure. The blanks are pre-dried and subjected to precise processing.

Thanks to industrial technology, glued profiled timber is distinguished by positive qualities:

- resistance to deformation in all weather conditions;

- strength;

- exact geometric dimensions, and as a result, smooth walls of the building;

- slight shrinkage, which speeds up the start of finishing work;

- a minimum of tools are used for installation, since adjustment is not required.

Adherents of ecology in construction call the presence of glue in the composition of the material a minus. However, bona fide manufacturers use only certified formulations. When purchasing, you must require documents confirming the safety of the product.

The main disadvantage for the developer is the high cost of the material.

Multilayer

The walls of the combined timber do not differ from the solid massif buildings.

The material consists of several layers:

- external walls made of wood;

- internal cavities are filled with insulation.

The camera can be one or several. Foamed polystyrene or stone wool is used as a heater.

Among the positive characteristics are:

- light weight, which allows you to save on the foundation;

- excellent thermal insulation properties - in the southern and middle latitudes, you can do without additional insulation of the house;

- the outer wall of the timber is made of high-quality wood, which excludes expensive finishing;

All these properties affect the final cost of construction, it is lower than from a solid bar.

At the same time, houses made of multilayer beams are sometimes considered not breathable - the foam does not allow vapors to pass from the rooms towards the street.

Product comparison

You can choose the right timber for the house when comparing various products by their main properties. It is necessary to take into account the cost of the timber itself, the cost of insulation and giving a decent appearance to the building.

the total cost

In ascending order of price, the timber is arranged in the following order:

- edged;

- edged profiled;

- profiled glued and multilayer.

For ordinary edged beams, high-quality insulation of joints and regular maintenance to eliminate cracks and cold bridges are required. External and internal finishing is required, insulation is required.

To be built from edged timber, you will need a special tool to adjust the material. Carpenter skills are required.

The profiled timber is easier to properly lay and insulate the joints. In most cases, facade finishing and mandatory interior cladding will be required, which will cause additional costs. The same work is foreseen by the construction of a multilayer material.

It is easier to build houses from glued and multi-layer types, but the material is 2-3 times more expensive than analogues. Savings are possible on finishing work, as well as due to the speed of construction - exact dimensions exclude fit.

Houses made of glued raw materials settle faster, the shrinkage itself does not exceed 2 cm per meter of wall.

Heat saving properties

The thermal conductivity of the wood itself is the same in different types of timber.

Heating bills are affected by the ease of construction and the quality of the insulation of the joints.

The most difficult thing is to caulk the edged timber.

The profiled version lends itself better to insulation, and sometimes the seams diverge only in houses made of profiled solid timber. This will require an annual inspection and sealing of the cracks.

To build a house from a bar, suitable for permanent residence, you need to carefully choose the material. The work can be carried out independently or entrusted to a contractor. Houses made of timber are environmentally friendly and warm, they serve for a long time if all construction conditions are met.