Painting of a metal fence is a measure due to the low resistance of the material to aggressive environmental influences. Precipitation, temperature changes and surface wear require iron protection. When choosing a paint for a metal fence for rust, you should also pay attention to the application technique and preliminary processing of the canvas.

LMC selection criteria

There are a lot of paints for a metal fence on the market - from the economy segment to the premium class. However, when choosing paintwork materials, experts recommend starting from the technical parameters of the composition, since the tool should be suitable for working with the material of the fence. Some manufacturers produce paints with additional anti-corrosion and decorative characteristics.

Acrylic based

In terms of protective properties, acrylic paints are not inferior to premium paintwork materials. Water-dispersion compositions are suitable for painting iron fences. The value of finishing materials is due to the following characteristics:

- service life 6-8 years;

- high level of elasticity;

- resistance to UV radiation;

- preservation of the original color;

- the composition includes anti-corrosion additives.

Acrylic based paints are non-toxic and non-flammable materials. Water is used as a solvent.

Some manufacturers offer a line of formulations with increased strength and resistance to mechanical stress.

Oil paints

This type of paintwork materials has good anti-corrosion properties for interior decoration, since it does not allow moisture to pass through. However, this composition is not suitable for the street due to its low resistance to temperature extremes.

The coating formed by oil paint, after drying, loses its elasticity and cracks quickly. Under the influence of UV radiation, the surface dulls and acquires a yellow color. When choosing which paint to paint a metal fence on the street, it is recommended to abandon this type of paintwork.

Compositions with anti-corrosion properties

The main advantage of the composition is its versatility. The paint is relevant for cast iron, steel, as well as non-ferrous and ferrous metals. Before you paint the iron fence, you need to decide with the manufacturer. Corrosion inhibitors can be applied to rusty fencing without pretreatment. The product prevents the development of corrosion, increasing the service life by several years.

It is allowed to paint pillars made of metal and concrete goods, welded structures made of reinforcement and other elements.

Blacksmith paint

A fence painted with a blacksmith paint will last 10-15 years without any defects. The coating is resistant to mechanical stress, humidity, sun and temperature extremes. This is due to the following advantages of the composition:

- easy to paint;

- drying of one layer takes up to 60 minutes;

- masking small defects;

- high adhesion;

- at the exit - a decorative view.

Apply the material after cleaning the surface from dirt. It is forbidden to use on old surfaces. A solvent is used for degreasing. The fence is pre-primed. Work with a spray gun, brush or roller is allowed.

Blacksmith paint is in the premium segment, but the quality justifies the investment as a result. The best option if the budget allows.

Rubber paint

Characteristics:

- eco-properties;

- incombustibility;

- elasticity;

- hydrophobicity;

- resistance to chemicals;

- protection against fungus.

For a long lasting effect, paint your iron fence after doing the following:

- clean the surface from corrosion, oil, old coating and dirt;

- sand the canvas until a matte shade appears;

- degrease;

- apply an insulating primer.

It is recommended to use metal fence paint at temperatures from +5 to + 40 ° C with a humidity level of 80-85%.

Hammer coatings

Paintwork materials are used for surfaces exposed to or already affected by rust. Hammer paint provides protection for the forged coating, and a fence made of profiled sheet or cast iron takes on a unique look. The surface of the products also receives the following properties:

- resistance to physical impact, including from impacts with a heavy object;

- elasticity remains under UV radiation and sudden changes in temperature;

- paint does not fade;

- the composition is not afraid of precipitation.

The application of the product guarantees an increase in the service life of the fence. As a result, the surface takes on the appearance of artistic forging, which is not afraid of hammer blows. In addition, the material allows you to hide defects in the metal structure.

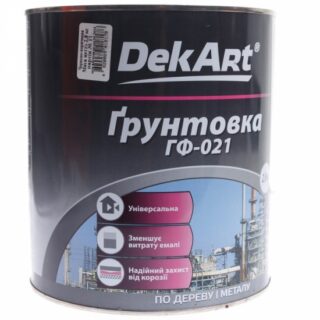

Primers

The main purpose of using a primer is to protect the metal fence from rust. The products strengthen the coating, increasing the adhesion level. It is applied before painting. Primers are distinguished by composition and technical parameters:

- insulating;

- phosphating;

- passivating;

- tread;

- inhibitory.

The range of manufacturers also includes brown anti-corrosion compounds with EP-0199 marking. The product is used for metal surfaces, including rusty ones. The product protects iron, increasing its resistance to aggressive environments.

The technology of applying paint to an old iron fence

Painting an old metal fence is a simple task, but to get a lasting protection for the iron, you need to prepare the surface. Applying paint on rust for a fence will be fast and of high quality if you adhere to the following rules:

- It is forbidden to apply enamel over rust. Remove signs of damage with special products. If not available, use a stiff-bristled brush. For greasy stains, solvent grade 647 or acetone is suitable. Dirt is washed off with rags and soapy water. Leave the surface to dry after cleaning.

- Corrosion that is difficult to eliminate, dust and cover with hot linseed oil, then apply paint with a roller.

- The first coat of paintwork should be thin. Brush the product into the surface for maximum penetration of the composition into pores and cracks.

- Coat a sheet of metal with traces of corrosion with a rust converter or a rust remover such as Weicon Rust Loosener.

- Apply a deep penetration primer. After drying, use paintwork materials with a suitable composition. To paint beautifully an iron fence, use a 3-in-1 primer-enamel and - such compositions are applied without prior preparation.

The selection of tools depends on the area of the canvas and the budget. A roller or brush is used for work. An electric spray gun cannot be used for thick compositions due to its low power.

To paint an iron fence, it is enough to apply 2-3 layers. Avoid dripping. To control the paint consumption, squeeze the roller or brush each time. When using a spray gun, select the optimal spectrum, as well as the spray power of the jet, depending on the thickness of the product.