Despite the fact that initially narrow wooden panels (siding) were used as a facing material for finishing the facades of buildings, it very soon became in demand for other purposes. This was largely facilitated by its manufacture from other materials. Recently, fences made of metal siding under a tree have become fashionable, which are gradually replacing the previously popular fences made of corrugated board from circulation.

Comparative characteristics of siding and corrugated board

Before comparing the characteristics of corrugated board and siding, it should be noted that these are still two different materials:

- Siding - narrow and long panels made of different materials (wood, metal, metal-plastic, etc.). Fasteners are not visible on the front surface of the material at the end of installation.

- Corrugated sheet - metal perforated sheet of different standard sizes. After mounting, fasteners are visible on its front surface.

The performance characteristics of these materials are different from each other:

- A siding fence looks more presentable than a metal profile fence.

- Unlike corrugated board, the service life of which does not exceed 15 years, siding is capable of providing a longer service life (up to 50 years).

- The bright colors of the siding fade over time under the influence of direct sunlight, while the covering of the corrugated board retains its decorative properties longer when the climatic conditions of use change.

- Siding is distinguished by a wide variety of decorative coatings; its range includes panels that imitate valuable wood species.

Fences from siding and corrugated board are assembled in different ways, but the installation of both is quite simple. A fence made of corrugated board is assembled faster.

The choice of siding for the fence

- wood: tree, ship board or "under a log";

- brick: yellowish, white, red and even with a pattern of artificial aging;

- a stone that looks like natural masonry.

Manufacturers recommend using metal, vinyl or cement siding for fencing. In this case, preference is given to metal, which has significantly fewer disadvantages.

Vinyl panels are less durable, their decorative paint quickly loses its attractiveness. Also, when installing and operating vinyl panels, special care must be taken due to their increased fragility.

Cement panels are heavy; during installation they require personal protective equipment (goggles, overalls, respirator, gloves). All this will be needed when sawing panels, which is characterized by the appearance of fine cement dust.

A metal siding fence, in comparison with other materials, looks more solid. Possessing the necessary rigidity, it is able to perform not only decorative, but also protective functions.

Metal siding

The metal-siding fence is a reliable and durable construction.The panels are made from oxidized aluminum or galvanized steel. The latter needs protection against corrosion, so it is additionally coated with polyester, plastisol, polyvinylidene fluoride, etc.

Standard dimensions of the metal panel:

- length - up to 400 cm;

- thickness - from 0.4 to 0.7 mm;

- width - from 20 to 25 cm;

- weight - no more than 4 kg / m²;

- operating temperature range: from -50 to + 80 ° С.

A metal siding fence is inherent in:

- resistance to changes in climatic conditions of operation;

- resistance to microorganisms (fungus, mold, etc.);

- long service life (at least 30 years).

Steel siding has one significant drawback - even an invisible scratch can cause rust.

Do-it-yourself installation of a metal siding fence

A fence made of siding under a tree or with any other texture is quite capable of installing with your own hands. First, you need to stock up on the necessary tools and prepare the site by clearing it of debris and foreign objects.

Required tools and materials

Depending on the selected fence design, you will need a different tool. If the arrangement of the strip foundation is provided, you will have to prepare:

- ax;

- formwork boards;

- a hammer;

- hacksaw;

- reinforcement and wire for binding the frame.

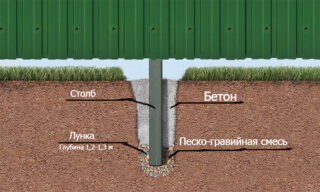

If you can get by with concreting the supports, you will need a drill to drill the recesses.

In both cases, you also need:

- shovels for excavation and concrete work;

- building level;

- plumb line;

- container for mixing the solution;

- metal supports of the required height.

From the materials you need to prepare:

- pegs for marking the territory;

- cement grade not lower than M-400;

- sand, gravel or crushed stone, water.

To attach metal corners to the posts, you need a welding machine. When adjusting the size of the siding, use a tape measure and a jigsaw. The siding panels are fastened with self-tapping screws, which are screwed in with a screwdriver or an ordinary Phillips screwdriver.

Pouring the foundation or concreting the pillars

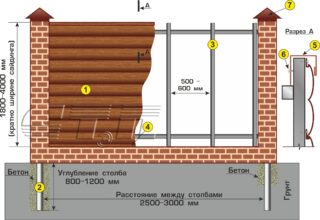

Before installing the supports, metal corners must be welded to them, to which the fence frame is attached. Welding points and corners are then coated with an anti-corrosion primer.

Frame installation

After the concrete has completely hardened, metal profiles are attached to the corners, which form the frame of the future fence. The profiles should be horizontal and parallel to each other. Attach them to the corners with self-tapping screws.

Having installed horizontal profiles, proceed to the installation of vertical strips. Install them in increments of 40 cm. Their length depends on the expected height of the fence.

Frame cladding

Before proceeding with the installation of the siding, it is cut to a length that corresponds to the distance between the centers of the support pillars. At the very bottom of the frame, on the first span, a starting bar is installed and screwed to the vertical elements of the frame with self-tapping screws. Then a siding panel is inserted into it and fastened with self-tapping screws to the frame. The rest of the panels are mounted in the same way. A finishing bar is placed at the top of the fence.

Operation and care

The service life of a metal-siding fence is determined not only by the quality of manufacture of the main elements and compliance with the rules for installing the structure. It also depends on proper care during operation.

The siding fence is maintained as follows:

- clean regularly using water and a soft brush;

- dirt and stains are removed with non-abrasive cleaning solutions.

Do not expose the decorative surface of the fence to corrosive solvents, pure chlorine and acetone.

The fence panels should be systematically inspected for scratches, dents and other damage. If defects are found, they are treated with a protective varnish or anticorrosive primer.