The fencing of a private land plot serves not only to mark its borders and protect it from the penetration of unauthorized persons, birds and animals. Another element of landscape design that defines the style of the courtyard and is its kind of facade. For the arrangement of spans, a wide variety of materials are used - slab, brick, netting, slate, picket fence. A worthy alternative has appeared on the market - a profiled metal sheet. The coating has excellent performance properties, but it requires taking into account some features during installation. One of them is the distance between the posts for the corrugated board fence.

What determines the distance between the supports

The profiled sheet is a metal plate processed by curly bending over the entire area, followed by the application of a protective composition. Depending on the purpose, the blanks are given certain shapes with different heights of the stiffeners. The thickness of the metal profile can be from 0.2 mm to 0.8 mm. Based on the parameters of the products, their operational characteristics are determined: bearing capacity, flexibility, strength, resistance to moisture and ultraviolet light.

When calculating the pitch of the posts for a fence made of corrugated board, the following factors should be taken into account:

- Metal nomenclature. The thicker and better it is, the greater the load it can withstand without changing the waveform and deformation in general.

- Site parameters. The more complex and smaller it is, the shorter the distance between the posts becomes. Usually it is 200 cm.With a large length of the fence, the intervals increase to 250-300 cm.

- Soil characteristics. The structures gradually fall into the sandy soil, the same happens with wet soils, where the soil under the foundation is washed out.

- The strength of the wind. The calculation is made for the maximum values that can mow or completely knock down the structure.

It should also be remembered about the subjective factor. We are talking about the activities of people when they work along the fence and the entrance gate. There is always the risk of catching the structure with a garden tool, wheelbarrow, leaning heavily or falling on it with all your weight. On problem areas, it makes sense to put poles more often, and the sheets are thicker.

Calculation Basics

The starting point for calculations is the characteristics of the site. In accordance with current legislation, the height of the blank fence between neighboring yards is up to 70 cm. It can be increased only with the written permission of the owner. For an external fence, the maximum value is 250 cm. Considering that the average height of an adult is 170-180 cm, 2 meters long panels are sufficient to create a fence.

The next benchmark is bandwidth. It is considered in two aspects:

- Complete. It is 120 cm from the edge, excluding structural connections.

- Working. It is equal to 110-115 cm. 5-10 cm goes to the connection in the overlay of waves along the edges.

If the sheets are installed vertically, the span size when the panels are joined on the posts is 220-230 cm without trimming when using two fragments. The use of three panels already gives 330-345 cm, which is rarely practiced, since it gives a critical windage indicator.

With the horizontal arrangement of the plates, the span width will be 195 cm with a height of 200-230 cm, depending on the number of stiffeners used to connect. Both those and other values correspond to the established norms.

The next value is the thickness of the metal. A 0.5mm plate is less expensive, but bends easily even under light pressure. The interval will have to be reduced, and the number of expensive supports will increase. 0.6-8mm panels are stronger but heavier. Spans can be made wider, and the foundation is more powerful.

A universal solution is to install thick and durable sheets with iron pipes embedded in the strip foundation. It is expensive, but durable and long lasting.

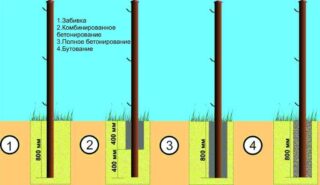

Varieties of supports

For the construction of the fence, supports are used from various materials, differing in appearance and in performance.

The main options are:

- Wood. A log is used, but more often a timber that is more convenient to use. Wood is easy to work with, but requires careful preparation before installation and constant maintenance. The main disadvantage is the tendency to rot and damage by insects.

- Brick. Pillars with embedded parts are highly durable, stable and presentable. To erect brick supports, you need a strong and deep foundation, the skills of a bricklayer.

- Metal. Pipes of rectangular or circular cross-section are used, there is no fundamental difference here. Iron is strong, reliable and durable, but inevitably rusts over time.

To reduce the construction budget without losing presentability, you can use various options for spans, combining the materials of their component parts.

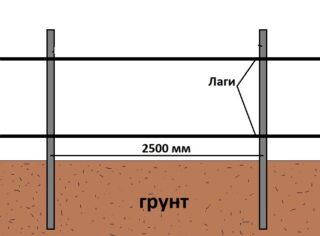

Calculation of the number of posts for a fence made of corrugated board

When calculating the number of pillars, the selected indicator should be taken as a basis for the location of the panels and the depth of the foundation. It is recommended to choose a width of 250 cm as a basis. This value is excellent for areas with medium density soil, humidity and moderate winds. In accordance with changes in conditions, the installation distances are respectively reduced or increased within the range of 10-50 cm.

As a rule, developers strive to maintain the same distance between the posts. This decision is quite justified, since the asymmetry is immediately evident. To avoid a large amount of waste, the span of the fence should be tied to the size of the available profiled sheet. If there is a need to deviate from the standards, for a small surcharge, the manufacturer will cut and send sheets of a given length with an accuracy of a centimeter.

To get the number of supporting elements required for construction, you need to divide the total length of the fence by the width of one span. Then take into account the space of the doors and wickets. In one case, the number decreases, in the other it increases. A more reliable way is to draw up a diagram, apply all the fragments of the fence and calculate the need. It won't take much longer, but the result will be more accurate.

How to determine the installation depth

The calculation is carried out according to the formula, where the area of the span and two constants - the aerodynamic coefficient (1.4) and the coefficient of the moment of resistance (22.5) - must be put into the equation. Briefly - (1x2): 3.

The panels must not be welded to each other or to the veins. Fastening should be done with rivets, since the bolts are easily unscrewed and the owners may one day be left with one frame.The edges of the sheets are not treated with a protective coating. You must do this yourself to prevent rust from developing.