Brick does not lose its relevance when building fences. The material is combined with metal, polycarbonate, corrugated board. A fence with brick pillars looks impressive and prestigious, it is equally suitable for summer cottages and land holdings with two-story cottages. An impressive fence is being built strictly according to technology, it has been serving for more than a dozen years.

- Which brick to choose for self-laying

- How to calculate material consumption

- Options for pouring the foundation for brick pillars

- Strip foundation

- Column foundation

- Stone foundation

- Mixing the solution

- Masonry technology in stages

- The order of work

- Brick laying for a bar

- Installation of mortgages

- Typical mistakes

Which brick to choose for self-laying

Red ceramic bricks and white silicate bricks are used for construction. During the acquisition of the material, attention is paid to examining the sample and studying the documentation from the manufacturer. Samples are viewed outdoors in natural light, not in a warehouse.

Selection parameters for quality blocks:

- when tapped, a properly fired brick sounds loud, and an unburned one emits a dull echo;

- on the area of all faces there should be no irregularities, cracks, chipped sections;

- on the surface, they do not allow whitish spots, lime inclusions that get along with the clay and eventually lead to cracking;

- bricks released at different times differ slightly in shade, so you need to purchase the material from the same batch.

Pay attention to the strength of the brick, which is designated by the brand from M75 to M300. Brick posts for the fence are laid M75 - M100. For frost resistance, for the northern regions, they use the Mrz100 brands, for a mild climate, they take Mrz50. The technical indicators of the material are in the passport of the goods.

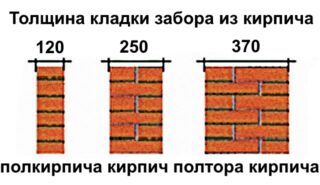

How to calculate material consumption

To begin with, determine the volume of brick pillars. To do this, measure the width, length and height of the product, then multiply and find the volume. Pillars of different sizes are counted separately, after which all cubes are added. The volume must be divided by the volume of one element to find the quantity.

The cubic capacity of one brick is calculated by its size:

- single - length 250 mm, width 120 mm, height 88 mm;

- one and a half —250 x 120 x 88 mm, respectively;

- double - 250 x 120 x 138 mm.

If there are non-standard, shaped bricks of irregular geometric shape, they are counted individually at the place of application. The pillars are full-bodied or made in the form of wells, which must be taken into account when calculating the volume of the masonry.

The size of the filling between the pillars is calculated so that one sheet fits, a section without cutting. For masonry, a solution is needed, the volume of which is determined at the rate of 0.235 m³ per 1 cubic meter of masonry.

Options for pouring the foundation for brick pillars

The base depends on the fence structure, filling weight, density and bearing capacity of the soil. The depth of freezing of the ground and the level of rising ground moisture are taken into account. In sandy soil without heaving properties, if the water does not rise more than 1.5 m, it is possible to deepen to 0.5 m.

Ideal conditions are not always present on the site. It should be borne in mind that frozen and wet clay or loam will squeeze the foundation up. The amount of movement depends on the weight of the filling between the posts.For example, polycarbonate is ductile, and a slight lift will not deform.

If a metal mesh or masonry is installed between the fence posts made of bricks for the fence, heaving will negatively affect the integrity of the fence and gate due to the inelasticity of the material. Before completing the foundation, a project is made, the length of the span is determined. The base should be 150 mm wider than the wall, and the trench should be made so that the formwork can be built.

Strip foundation

At the bottom, a cushion of sand and crushed stone is laid with a height of 10 and 15 cm, respectively. The material is compacted with wooden rammers, spilled with water to settle. Expose the formwork from boards, OSB sheets, which are fastened with bars. For fixing in the required position, struts, supports are used. The top of the formwork is fastened with transverse strips so that the concrete does not collapse the walls of the formwork.

Reinforcement is made with longitudinal bars of corrugated or smooth reinforcement with a diameter of 10 - 14 mm. For heavy fences, a metal frame is installed. The rods are welded or connected into a spatial structure with a knitting wire. The concrete is poured so that there are no clear joining points, and the connection is carried out according to the type of escape groove.

Column foundation

Step-by-step construction procedure:

- Marking the position of the supports and pits (after approximately 1.5 - 2.0 m), for which the stakes are driven in and connected with wire.

- They dig holes around the pegs, the average depth is 1.0 - 1.5 m (varies depending on the freezing height), the diameter or cross section is 25 - 45 cm.If the fence is made on a slope, each base is made with a difference of 15 - 20 cm in height from the previous one.

- A metal pipe is treated with a primer and painted at least 2-3 times.

- Crushed stone and sand bedding is carried out, a pipe is inserted into it by screwing. Each layer of backfill is poured with concrete.

After the support has solidified in the mounting position, the remainder of the pit is poured with concrete, vibrated and waited for strength.

Stone foundation

The stone base is installed under a fence with brick columns and heavy infill, for example, in the form of forged gratings. In this case, the top of the foundation usually protrudes half a meter above the ground. A trench is dug under the masonry, the bottom is reinforced with a pillow of sand and gravel. The laying is carried out with the selection of stones so that there are no gaps. For connection, use a solution of sand and cement.

The first row is made of large elements, gradually decreasing in size towards the top. Small stones are used to bundle large blocks.

Before installing the walls, the bottle is washed with a water jet, cleaned of dirt. Wet walls do not take moisture away from the solution; the mixture sets under normal conditions.

Mixing the solution

Usually cement M400 or M500 is used, sand is used in fine fractions.

The resulting solution is also distinguished by brands:

- M25 is obtained at a concentration of cement, sand 1: 5;

- M50 - the ratio of cement to sand is 1: 4;

- M75 - fortress 1: 3.

Brick pillars for the fence are laid with the M75 brand.For 1 cube of solution, 350 liters of water will be required, 425 kg of cement grade 400 and 1125 kg of sand are also mixed. A large volume of the solution is prepared in mortar mixers. If the number of posts is small and the fence is short, you can mix the mortar with a shovel in a trough.

Concrete is prepared in a ratio of 1: 3: 5, water is taken 0.5 parts of the volume of cement (M400 or M500).

For 1 cube of solution mix:

- 213 kg of cement;

- 563 kg of sand;

- 1250 kg of crushed stone.

The dry components are loaded into the drum of the concrete mixer immediately before mixing. Water is poured first, then cement is added. The sand is added and the drum is turned on for 2 to 3 minutes to mix the ingredients. After that, add crushed stone and mix.

The total kneading time should not be more than 10 minutes, so that the mass does not start to set. The mixture is consumed within two hours.

Masonry technology in stages

They start with the preparation of a site for the construction of a fence with brick pillars. Bushes are removed on the line of passage of the fence, old fences are dismantled. The boundaries are marked on the territory with the help of stakes and a cord, while not only the dimensions of the brick columns are marked, but also the outlines of the pits and trenches under the base are determined.

Turns are marked with a square if they are straight. For a different type of curvature, straight cords are used, crossing which will show the place of the turn. The stakes are placed 1 m apart from each other. Parallel to the first line, the second marking is pulled along the width of the pillars. The dimensions of the pit are marked under each column. Determine the place of entry in the form of a wicket and a gate.

A place for storing sand, crushed stone and cement is organized nearby in order to reduce the distance of delivery and transportation by wheelbarrows. The bricks are brought up after the concrete mixture has been laid, when the space around is cleared and there is room for unloading the pallets.

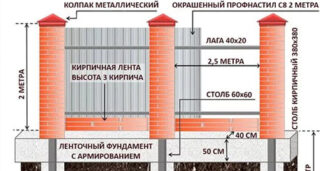

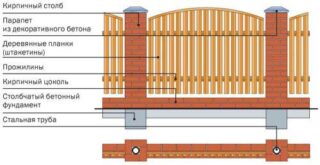

The order of work

A classic fence with brick columns is built according to a specific technology.

The stages include:

- Foundation device. The type of support part is chosen so that it can withstand the weight of the posts and intermediate fence sections.

- Brickwork. Construction begins after 50% of the strength of the foundation has been gained, the waiting period is 10 - 12 days. The size of the posts (1.5 - 2 bricks) depends on the height and severity of the fillings. The masonry is checked with a building level and a plumb line, in the process they put embedded parts.

- Installation of sections or tape filling of spans. To do this, a mesh frame, forged parts, a frame for polycarbonate or corrugated board are welded to the embedded frames. A solid fence is made of brick.

- Installation of decorative elements. The pillars are covered with metal tiles, the caps are also placed over the fence sections. Such details decorate the fence and protect the material from destruction by rain and snow.

Installation of wickets, gates is the final stage of construction, after which the fences are ready for use. More often, metal products made by welding or forging are combined with brick pillars. In combined types of fences, the same materials are taken to fill the entrance structures as for the spans.

Brick laying for a bar

Metal rods are placed horizontally and vertically between the rows of masonry to obtain perfect and uniform seams. The thickness of the smooth reinforcement is 10 mm, a circular section is used, because the square bar is difficult to move.

They begin to lay from the corner, so the first piece of the rod is placed in this area. Corner bricks must grip tightly, a marking cord is placed on top of them for laying subsequent bricks. The second row is laid after the first has dried. A solution is placed on the reinforcement, and a stone is placed. The brick is tapped with a mallet until it is completely settled on the bar.

While the row dries, the elements are pricked on the other side of the pillar. The bar can be placed along the entire row or laid only under the corner stones, and the rest of the elements can be clearly aligned along the cord. To beat off halves and three fours, use a grinder to get an even edge, you cannot beat off with a pickaxe.

Installation of mortgages

The ideal surface of a brick pillar looks beautiful, but you need to attach sections of spans to the support, fix the wicket and gate posts. Therefore, during construction, metal embedded parts are placed in the body of the columns in order to subsequently weld steel elements to them.

There are many types of parts, each performs a specific function. If filling is done with solid masonry, embedded elements connect the sections to the columns. To do this, put metal loops from rods with a diameter of 6 mm in 3 rows.

For infills made of profiled sheet, polycarbonate, metal frames are attached to the posts. Embeddments are made in the form of steel plates so that they can withstand the weight of the spans. For installation, a brick is sawn so that the part becomes there. Later, logs are welded to the embedded elements, and sections are placed on them. You can load the pads after the final solidification of the solution and the gain of 100% strength (28 days).

Typical mistakes

Often, the fence is set opaque to block any visibility, or decorative options are used that are fully visible. The optimal solution would be a fence made of euro shtaketnik, which is characterized by average protection from prying attention.

When erecting, they forget to control the horizontality and verticality, as a result, the upper and lower rows are obtained with different seam heights, and the vertical ones are shifted to a different interval. Pillars look beautiful if they have perfect geometry.

Before installation, the brick must be dipped in water so that it does not draw moisture from the solution. If this is not done, the masonry will turn out to be fragile and short-lived. The first row is first laid out on the base without solution. If you miss such a moment, the number of elements may not match and you will get cut pieces.

The wrong construction season leads to the fact that work is carried out in winter at low temperatures. Concrete in the cold does not set, but freezes; after thawing, the structure begins to float. Support pillars are mounted in frozen soil, and when the ice melts, they warp.