In apartment buildings, as a rule, plastic windows with double-glazed windows are installed. It is a sturdy structure that requires minimal repair and maintenance work. Due to the rather high cost, not every apartment owner can use this option. In structures with wooden frames, the function of insulation and protection of the material from destruction is performed by putty for windows.

The need for putty for windows

During operation, the frame body often begins to crack. In this case, water gets into the cracks, contributing to a deterioration in the performance of the product. Putty for wooden windows will help prevent this process and repair cracks and other damage to the integrity of the frame body. Also, its use minimizes heat loss and prevents the installed glasses from rattling.

Window putty seals wood and glass structures where the two components meet. The homeowner can make the mix themselves or purchase a ready-made mix from the store.

Industrial products contain ingredients such as nitrocellulose, drying oil, polymer compounds. The most common form of release is a paste that does not require mixing with other components.

Powders produced in sachets are common. They need to be diluted with water. With a wide range of colors, the homeowner can purchase a product to match the color of the window frame.

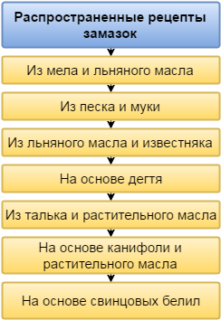

DIY cooking methods

There are several ways to make window putty at home. For the preparation of mixtures, chalk, drying oil, vegetable and animal fats are used. The finished substance must have the following qualities:

- lack of tendency to crack, exfoliate, plasticity;

- sufficient service life (at least 1 year);

- high-quality adhesion to the planes of the structure;

- fast hardening;

- resistance to the action of the sun, humid air and temperature fluctuations.

Before covering the windows between the frame and the glass, you need to carefully inspect the structure and determine how much mixture is needed. It is advisable to prepare it with a certain margin.

Drying oil and chalk

Chalk and linseed oil

This is one of the most popular DIY methods for making window putty due to its good performance and availability of ingredients. It is often used by specialists working with wooden windows.

The chalk is rubbed on a fine grater, then passed through a sieve. Oil is added to the resulting powder in an amount of 25% of its volume and mixed thoroughly. The final composition should resemble dough in consistency and roll into balls. If it is not thick enough, you need to add more chalk. The putty calmly tolerates temperature fluctuations, in a dry state it has a yellowish color. Coloring compositions can be applied to it.

Cement and vegetable oil

Here, not the oil itself is used, but the sediment resulting from settling.Only unrefined fats are suitable for work. You can use drying oil instead. Decorative cement, in turn, can be replaced with grated chalk. The mixture contains 20% fat and 80% loose. The finished mixture should look like thick sour cream. It is distinguished by a long service life (more than a year), lack of tendency to shatter and cracks, tolerates a wide range of temperature indicators without problems. Due to the availability and low cost of components, it will be more profitable to prepare such a putty with your own hands than to buy a ready-made one.

Tar and ash

Such a composition is also easy to prepare, but it tends to harden quickly, so you need to make a putty right before using it. The tar is cooked for 2-2.5 hours over medium heat. At this time, you can prepare wood ash: it is crushed and then sieved through a two-layer piece of gauze or a sieve. Then the tar needs to be cooled so that its temperature becomes room temperature. Ash is added to it and kneaded by hand, like a dough, until the mixture stops sticking to the skin.

Sand and flour

It is a very cheap mixture that can insulate a house when used from the inside of a window structure. In this case, it can last for several years. But it is not suitable for external frame termination. Another drawback of the mixture is that it is not very plastic. Nevertheless, it is quite suitable for embedding when the frame needs to be repaired urgently, for example, in the country, and there are no other ingredients in the nearest access. Well washed and dried fine sand must be thoroughly mixed with the same amount of flour. Then water is added to the bulk mass. There should be enough of it to make a thick paste.

Rosin, chalk and ghee

Such a composition can be stored for a very long time if you put it in a hermetically sealed container and refrigerate. You can use it immediately after preparation or put it off for future use. The main ingredient here is grated chalk. Lard and rosin crushed into powder are taken in amounts equal to 10% of the chalk volume. Animal fat will need to be heated in a water bath. Rosin is added to it and kept on fire until the mixture becomes liquid. Then chalk is poured there. The final mixture should be thick and have high plasticity.

Applying putty for windows

Before using the putty, you will need to prepare the necessary tools. A rubber spatula is needed to install the plastic mixture into the crevice spaces. The old putty is removed with a chisel. A construction knife is also suitable for this purpose. You should also purchase coarse sandpaper and a primer for wood surfaces.

You need to do the work in calm weather at temperatures above +5 degrees. Wind gusts are likely to interfere with the quality of the installation.

First, remove the old sealant with a suitable tool. To remove stubborn parts, you can heat them up with a hair dryer. Then wood surfaces are treated with sandpaper and primed. When the mixture is dry, you need to check the quality of fixing the nails that hold the glass elements. They are replaced if necessary. A flagellum is rolled up from the putty and placed at the junction of glass and wood. It is pressed into the gap and leveled with a spatula. A similar operation is performed on all butt areas.