Laminate is a popular flooring in residential and commercial construction. The material has a presentable appearance, strength and durability, ease of installation and maintenance. Even the highest quality and most beautiful structures can be damaged due to violation of the rules of installation and operation. If small surface defects can be repaired on site, then the entire fragment must be replaced to eliminate large damage. It is possible to replace one laminate board without disassembling the entire floor. To do this, you need to familiarize yourself with the methods of carrying out partial repairs, acquire the necessary equipment and exactly follow the recommendations set out below.

Description of the structure of the laminate

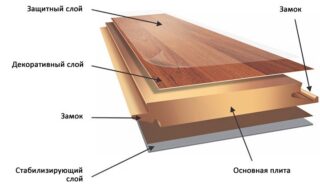

Laminate consists of shortened boards up to 22 cm wide and up to 80 cm long. Along the edges of the products there are locks in the form of grooves and ridges, on which the docking of the flooring parts is carried out. The panels consist of the following layers:

- Top (front) - welded film or polymer spraying. Performs the role of protection against moisture and mechanical stress.

- Decorative - gives the panel a pattern and color. It is made of natural veneer or thick colored paper.

- Base - is responsible for the shape, volume and fastening in the flooring. Made of high quality fiberboard or PVC.

- The bottom (backing) is made of foamed polymer or cork. Serves for tight adhesion of the covering to the floor and providing sound insulation.

There are models with straight edges and with chamfers on two or four sides of the lamella. Connections can only be made with locks and with additional fixation with glue. It is almost impossible to disassemble the glued floorings, which must be taken into account when planning the replacement of a part of the covering.

The need to replace the laminate partially

The layout of the interior of most of the premises is standard - along the walls and in the corners, there are furnishings, the center is free. Based on this, the passage area is most at risk of damage.

The need to replace the laminate may partly arise for the following reasons:

- a large dent from the fall of a heavy object;

- swelling due to spilling liquid or washing floors with a deck method;

- long through crack due to thermal deformation;

- consequences of local fire;

- damage to the front side with active chemical reagents.

Parsing the flooring is the best way to change a defective part, but in most cases it is impossible for one simple reason - dismantling must be carried out from the wall, and there is furniture that has nowhere to take out. Therefore, it is necessary to replace the panels without disassembling the cover.

Necessary tools and equipment for work

The process of restoration of a laminate floor itself is not particularly difficult, but for its implementation it is necessary to have some special equipment.

To replace the laminate flooring in the middle of the room, you will need to buy or rent the following tools:

- hand cutter or grinder;

- nail puller;

- pliers;

- rasp;

- ruler;

- marker;

- file;

- chisel;

- assembly gun;

- molded glue.

The work is somewhat dangerous.Therefore, it must be performed with goggles and gloves.

Features of partial replacement of laminate

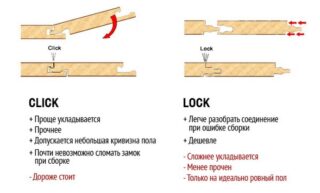

There are such types of lock connections:

- Collapsible "Click". The docking unit is of a swivel type, which makes it possible to disassemble and accurately dock a new fragment.

- Non-collapsible "Lock". The connection is made rigid when the spike is driven by a blow into the groove and firmly sits in it. It is almost impossible or extremely difficult to remove the faulty fragment without breaking the lock.

If, when installing a laminate floor, glue was used in the locks, such a shield can be considered as non-separable. Attempts to dismantle it will end in breakage and disposal of the panels.

Operating procedure

Having decided on the type of material and the features of its assembly, you can begin to repair the coating. Initially, you need to select the panel of the desired model and the best suited for the pattern and shade.

A certain technology is used depending on the model of the locks.

With CLICK-locks:

- Connect the corners of the lamellas with diagonals. Measure 2 cm from each corner, connect these points into a rectangle.

- Make cuts with a milling cutter or grinder, first extract the cut off fragment, and then its edges from the adjacent lamellas.

- At the new part, use pliers to break off the side ridge and both lower parts of the grooves. Clean these places with a rasp and file.

- Clear the opening from debris, try on. If necessary, place props to level all contours.

- Lubricate the edges of the new panel with glue, insert it into the opening at an angle, lower it until it snaps into place and press down with pressure. Remove glue residues.

The restored floor can be used immediately after the mortar has dried.

With LOKK-locks:

- Draw a rectangle inside the defective board with sides smaller than its size by 1.5-2 cm.

- Saw out the shape, cut the outer and inner corners together.

- Remove the cut fragment by grasping it with a screwdriver. Raise the flooring with a nail puller, pull the side strips out of the grooves.

- Clean the groove and side ridge on adjacent boards. On the new part, grind off the ridge under the wedge and remove the lower level of the rear groove. You will get 2 support faces.

- Carry out cleaning of the opening, fitting and fitting of the new panel.

- Lubricate the joints with glue, connect the front parts of the boards, lower the part into the opening and press firmly until it reaches the horizontal.

After the glue dries, it remains to putty the remaining cracks on the sides.

Using the methods described, you can partially replace the laminate from the center of the room to the outside of the furniture standing against the wall. This work is completely analogous to the methods described above. It is not a separate board that is cut and removed, but whole strips of damaged material. The assembly is carried out either by separate panels or by structures docked into a long rail.