The roof is a part of the house that is constantly under stress, sometimes reaching critical values. The covering material is exposed to ultraviolet radiation, moisture, high and low temperatures. All this leads to a gradual deterioration in the operational properties of roofing materials, their accelerated aging, and the emergence of risks of leaks. Developers are faced with the task of choosing the right roof covering and its regular repair. Liquid roofing is a versatile, quick and effective solution to both issues.

Liquid roof composition

Liquid roof rubber is an innovative waterproofing material that includes bitumen emulsion and latex. Upon contact with air, the mixture hardens, in a matter of minutes passing into the stage of a dense elastic film with a high degree of adhesion to almost any surface.

By the number of components included in the composition, liquid rubber for roofing is divided into the following types:

- Multiple. They contain a base substance and a catalyst, which, when added, initiates the hardening process of the mixture. The product description contains recommendations for the proportions of ingredients.

- One-piece. Materials of this group are kneaded in advance. Hardening begins after applying the liquid to the treated surfaces. The mastic is ready for use immediately after purchase.

The basis of the coating is an aqueous bitumen-polymer emulsion, which is completely safe for people and the environment. To achieve the desired decorative effect, water-based dyes are added to the mixture.

Liquid roof production

The base of the mastic is liquid bitumen, to which polymer additives are added. Due to this, the process of evaporation of essential oils does not occur, the coating retains its strength and elasticity.

Liquid membrane for roofing has the following performance characteristics:

- Low fluidity. The material can be applied to horizontal, inclined and even vertically oriented surfaces.

- UV resistant. No additional protection required.

- Maintaining elasticity at high and low temperatures. Lack of effect of expansion and reduction in size.

- Waterproof. The mixture of bitumen and polymers forms an airtight film, in which there are no joints and seams.

- Long service life. The products of the best manufacturers are designed for 25 or more years of service, regardless of weather and climatic conditions.

- High strength. After curing, the coating is strong enough to be walked on safely.

An important factor in favor of choosing liquid rubber is its incombustibility and resistance to chemical reagents used in construction. The material has only one drawback - high cost.

Varieties of materials and their features

The cold technology of applying mastic is highly efficient when the material hermetically fills all cracks and irregularities.

To do this, you can choose the following types of mixtures:

- Liquid rubber. The solution is made on the basis of rubber with polymer additives. The rubber roof is of medium strength and has a characteristic black color.

- Mastic. Refers to the category of bulk materials. It is applied to the substrate with a brush or roller.

- Liquid glass. It is the most effective and expensive roofing coating. It can be applied to the surface with a spray gun or manually.

- Bituminous polymer. The most common in household and industrial construction. Differs in fast hardening and high elasticity.

All types of coating can be used to create a new layer and to restore the tightness of an old roof.

Necessary tools and materials for work

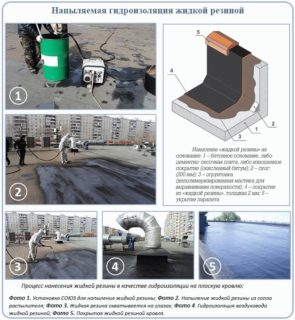

The technology for creating a liquid roof involves applying the material in various ways. The choice is determined by the working properties of the mixture and the working conditions:

To complete it, you will need the following devices:

- roller;

- brush;

- steel spatulas;

- scissors;

- sand;

- brush;

- spray gun.

The solution is purchased in the amount necessary for the treatment of the roof over the entire area with a margin of 10-15%. The material consumption is indicated by the manufacturer on the packaging.

Self application

Arrangement of a liquid roof consists of the following stages:

- Measurements and calculations. Purchase of materials and equipment.

- Preparation of the base. Garbage, old roofing material and dusting are removed from it. Finally, dust is removed. If necessary, drainage structures are leveled.

- Impregnation of concrete with bitumen emulsion. It is advisable to do this twice so that the liquid penetrates 1.5-2 mm into the base.

- Preparation of the mixture, if provided by the instructions. The finished solution must be mixed well so that it is completely homogeneous.

- Application of mastic. This is done in one of the ways - with a brush, roller or spray. The solution is evenly distributed in a layer of 3-4 mm.

- Wait for the mastic to harden and apply a second coat of the same thickness.

- Staining of the hardened surface. This is done for design purposes, if the roof is used for any domestic purposes.

For additional protection against mechanical damage, the polymer coating is sprinkled with sand or fine stone chips.

Liquid roof repair

Replacing an old roof covering involves quite significant costs and labor costs. It is much easier, cheaper and no less high quality to carry out roof repairs using polymer mastic.

First of all, the working area is cleaned, the damaged areas are degreased and primed. Large cracks are covered with a mixture of mortar and sand. Small holes are filled with a mixture, and then the surface is leveled with a spatula. Gaps in the roofing felt are closed by installing patches. Around the damage, a solution is smeared onto which a building bandage is laid. Then this place is covered with mastic. Unavoidable contamination from clothing and tools can be easily wiped off with technical alcohol or acetone.