After a long operating period, any heater becomes unusable and needs to be replaced. Often the owners of apartments and private houses choose between an aluminum or bimetallic radiator. To decide, you should find out about the pros and cons of each product and compare their characteristics.

- Comparative characteristics of aluminum and bimetal

- Aluminum radiators

- Bimetallic batteries

- Pros and cons of aluminum radiators

- Advantages and Disadvantages of Bimetallic Batteries

- Which batteries are better to choose

- Antifreeze in an autonomous heating system

- Antifreeze types

- Features of mounting radiators

- Connection methods

- Manufacturers and models of aluminum and bimetallic radiators

Comparative characteristics of aluminum and bimetal

Since cast iron batteries are outdated physically and morally, they are being replaced with more modern models. To find out which heating radiators are better - aluminum or bimetallic, you need to understand their structure, heat transfer rates, resistance to water hammer and pressure drops, durability, cost.

Aluminum radiators

An aluminum radiator is a series of interconnected sections that have protrusions and fins that increase surface area and improve heat dissipation. Such batteries can be:

- cast - with sections of one-piece type;

- extruded - sections are mechanically connected;

- combined - combine both types.

Sectional batteries are manufactured from sections that are manufactured by injection molding. They are interconnected by nipples - threaded connecting elements. These radiators can be extended and damaged sections can be replaced. But they are less reliable at the expense of connections.

One-piece radiators are made of extruded profiles and welded together. The design is non-separable, which excludes the possibility of building up during operation. Aluminum retains its plasticity, since there are no additives in it, which excludes cracking and spalling of ribs during external mechanical stress and internal water hammer. The batteries are durable and reliable as they do not have cross-section gaskets. If from the inside they are coated with polymer, then their service life may be higher than cast iron.

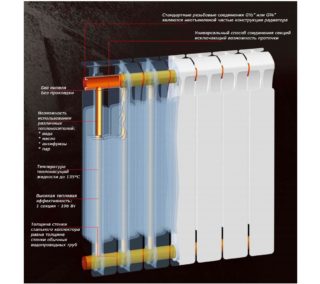

Bimetallic batteries

These products, unlike the previous ones, have a steel inner element. Depending on the design, radiators are:

- full or reinforced bimetal - the one-piece steel core does not come into contact with external aluminum;

- with part-steel core - steel tubes are only available in vertical ducts.

Compared to aluminum radiators, bimetal heat transfer is 15 -17% lower. The price is much higher.

Pros and cons of aluminum radiators

Aluminum models have many advantages:

- a light weight;

- high thermal conductivity - they give off half of the heat by convection, and radiate the rest;

- elegant appearance;

- affordable price;

- working pressure 12-16 atm., pressure test - 18 atm .;

- cross-section of large-area intercollector tubes.

In addition, with the thermal heads, the batteries are easy to regulate as they contain a small amount of water.

The disadvantages include the following points:

- potential corrosion above pH 7;

- an air vent valve is required to remove air;

- the threaded connection is considered the most vulnerable.

Aluminum is an active metal.In the event of a violation of the integrity, the oxide film covering it, when interacting with water, begins to decompose, releasing hydrogen. If the product is sealed, pressure build-up may cause the battery to rupture. To prevent this from happening, surfaces in contact with water are coated with polymers.

Polymers prevent blockages, reduce flow resistance and allow the use of a heat transfer fluid with a higher pH (up to 10). If there is no polymer inner coating, it is unacceptable to turn off the valve on the supply pipe.

Advantages and Disadvantages of Bimetallic Batteries

The use of a steel core protects aluminum from high working pressure and interaction with the coolant, which excludes corrosion. The advantages of the products are as follows:

- high strength - they can be destroyed by a pressure of 100 atm;

- durability;

- high level of heat transfer;

- modern design.

The only drawback is the highest price among all batteries.

Which batteries are better to choose

Radiators should be purchased depending on the operating conditions. In a multi-storey building with central heating:

- water hammer is likely due to sudden pressure drops;

- the quality of the coolant is low;

- water temperature changes due to seasonality and weather.

Aluminum will not withstand such loads, therefore, bimetallic radiators with a stainless steel core should be installed in high-rise buildings (over 16 floors). Weighing all the advantages and disadvantages of different models, we can conclude that mixed types of products with 2 vertical channels and a pressure pressure of up to 27 atm are suitable for an ordinary "Khrushchev" or 9-storey building.

In the private sector, the operating conditions are different. High-quality boilers can provide pressure up to 10 atm. At the same time, water quality and temperature are under control, and water hammer and subsidence are excluded. Therefore, cheaper aluminum radiators are quite appropriate here. They have an attractive appearance, sufficiently high heat transfer, and cast batteries have a long service life. If funds allow, bimetallic radiators can also be installed in a private house or cottage.

Antifreeze in an autonomous heating system

Antifreeze can be used to extend the life of aluminum batteries. If the water in the batteries can freeze and break them, then special fluids remain fluid even at temperatures of minus 60 degrees. They do not harm aluminum, but they heat up a little longer than water, and have a high level of thermal conductivity.

Negative properties:

- viscosity - a sufficiently powerful boiler is needed to move them in the heating system;

- toxicity - it is necessary to observe precautions during use;

- violation of the integrity of the elements of the joints of the heat conductor is unacceptable.

For autonomous heating in aluminum radiators, antifreeze is preferable to water, since it increases their service life. The durability of the coolant is 10 years, during which the metal does not change at all.

Antifreeze types

Heat carriers consist of distilled water and a certain additive:

- Antifreeze with ethylene glycol. Cheap, extremely toxic if accidentally ingested. Long service life. It can be used in a single-circuit boiler due to its high toxicity.

- Glycerol. The supplement is highly soluble, non-toxic, does not precipitate.

- Propylene glycol. The best supplement is non-toxic, no sediment, but pricey.

When using antifreeze for heating, batteries with a large number of sections will be required, since its heat capacity is lower than that of water. When heated, it expands greatly, so the capacity of the radiator should be 50% more.Rubber is used as gaskets in the network, and sealant is used for all joints and connections.

Features of mounting radiators

When installing batteries yourself in a private house or cottage, the following rules and regulations should be observed:

- radiator length - 55-75% of the width of the window opening;

- distance to the wall - 30-50 mm, to the floor - from 100 mm, from the window sill - from 50 mm;

- batteries should be mounted under the window, not far from the door - in places with the greatest air circulation;

- the central axis of the radiator coincides with the central axis of the window, the recommended deviation is 20 mm.

If the wall is covered with a foil screen with a heat-reflecting effect, the permissible distance to the radiator can be reduced to 25 mm. At the same time, heat is saved by 15%.

When installing bimetallic or aluminum radiators, the packaging is not removed from them until the end of the work in order to avoid accidental damage. With natural circulation of liquid in batteries, it is permissible to mount up to 12 sections, with artificial circulation - up to 24. In addition to radiators, you will need:

- sealant;

- sealing tape;

- torque wrench;

- thermostats and valves;

- fasteners (brackets);

- squeegees of different sizes.

Thermoregulators, shut-off valves and a Mayevsky valve are installed on the batteries, through which air is released. Brackets are attached to the walls according to the level, radiators are hung on them. They should hold tight, not sway. Then the plugs are unscrewed, with a one-pipe system, a bypass with a valve is mounted, with a two-pipe system, a squeeze with a valve. With a torque wrench, connect the pipes with the squeegees so as not to overdo it when tightening the nuts (the torque limit is indicated in the instructions for the fasteners). A loose connection can lead to leaks. The joints are sealed with a sealant or sealant.

After installing the heating system, it is necessary to pressure it, for which a plumber is called. At the end, a test run is made and imperfections are eliminated, if necessary.

Connection methods

You can connect in series and in parallel. The first method involves a closed system in which the inlet pipe of one battery is outlet for the other. If there are no bypasses to repair one battery, the entire system must be shut down. A bypass is a tube that connects the input and output of each battery. In parallel, each radiator is connected to the main pipe.

Manufacturers and models of aluminum and bimetallic radiators

The most famous brand of batteries is Global, the best Russian manufacturer is Rifar; Royal Thermo has the best prices; Sira has performance and quality; Thermal has a ratio of characteristics and cost. The last representative of the segment produces inexpensive aluminum batteries, for example, RAP-500. They are most suitable for installation in a cottage or private house, since their output is 252 W and can withstand a pressure of 60 bar. At the same time, the price remains at the average level.

Until recently, Sira was one of the best companies, but after moving its production facilities to China, its rating dropped significantly. For models of aluminum radiators - SIRA Emilia 500 and bimetallic SIRA RS BIMETAL 500 heat transfer reaches 200 W.

Royal Thermo is a Russian manufacturer of batteries with an Italian design, which has a high position in terms of sales and level of trust.The main type of products is represented by bimetallic (ROYAL THERMO BiLiner 500) and aluminum (ROYAL THERMO REVOLUTION 500) radiators with heat output of 170 and 180, respectively.

Rifar is a domestic company on the heating equipment market since 2002. At a low cost of batteries, bimetallic (RIFAR MONOLIT 500) and aluminum (RIFAR ALUM 500) radiators have good performance. They have a heat transfer of 180-185 W, high temperatures of the coolant and carried out pressure.

The global brand Global in its models combines European quality and Italian design. It has been producing the best aluminum and bimetallic batteries since 1971 and occupies 38% of the world market. Global is the only European company that has not moved production to China.