The operation of any heating system must be designed for a certain temperature regime. However, it is not a constant value, since external factors change - the temperature outside, the required level of heating at home or a separate room. For the timely control of these processes, automation is needed for heating with gas and electric boilers and pumps. What requirements should be taken into account when choosing it?

Purpose of automatic heating systems

Ideally, the heating system should maintain the optimum temperature in the house or apartment. For this, in modern boilers (electric or gas), controllers are provided for the degree of heating of the coolant and its pressure in the system. In addition to it, automation is installed for gas heating boilers or electric models.

Despite the fact that manufacturers are trying to take into account all the nuances when designing heating equipment, there is a certain area of monitoring its operation, which can be carried out using additional devices. Depending on the purpose, automation for heating boilers can be of the following types:

- Security... These include burner operation sensors, protection of electronics against voltage surges;

- Additional methods of regulating the heating operation mode... By installing an automatic control unit, you can achieve optimal system operation by changing the degree of heating of the coolant. Moreover, many models provide the ability to connect external temperature sensors;

- Optimization of costs for heating water in pipes... For this, blocks for mixing the heated and cooled coolant are installed with varying degrees of automatic operation.

To select the optimal model of heating control systems, you need to familiarize yourself with their varieties. Each of them must have certain performance characteristics. Correctly selected automation for the heating system should simplify the control of the system operation, as well as reduce the current costs of the energy carrier.

Before purchasing an automation complex for a specific heating boiler, you need to find out the possibility of connecting devices to each other. This is indicated in the operating instructions.

Automation for heating boilers

The operation of any type of boiler must be efficient and safe. The latter quality is mandatory and for this it is necessary to provide for a number of protective measures. First of all, this applies to gas models of heaters. However, for the user, all two parameters are equally important. Therefore, automation for electric heating boilers or gas models is made combined. One module has functions for optimizing energy costs, checking the safety of the device and changing modes depending on external factors.

Manufacturers offer two types of automation for gas and electric heating boilers: remote and direct connection. The first ones are convenient to use when arranging the control unit directly in the living room.

Gas heating boilers

In the overwhelming majority of cases, modern models of gas equipment are already equipped with all the necessary elements of safety, control and automatic regulation of work. However, for older type boilers, it is recommended to periodically upgrade. First of all - to make the installation of new automation for gas heating boilers.

Installing a new gas burner control unit will improve the following boiler parameters:

- The ability to adjust the temperature of the water in the system. Installation of new automation for gas heating boilers in conjunction with connected temperature sensors in the room will allow you to adjust the air heating mode in the house;

- Gas flow control - from maximum to minimum;

- Automatic shutdown when the gas pressure drops or reverse draft occurs;

- Saving energy consumption up to 20% - depends on the model of automation for heating boilers;

- Shutdown of equipment in case of emergency - lack of gas, electricity or pipe burst.

The average cost of such blocks can range from 3400 to 6700 rubles. However, these functions are not sufficient for the user. Therefore, you will need another type of automation for the heating system - programmers. These are high-tech devices that can be connected to almost all types of modern boilers. Programmers are designed to set heating operating modes when external factors change - outdoor air temperature, time of day, etc. Installation of temperature sensors is required as additional modules. Such weather-dependent automation of heating systems provides the following advantages:

- Water temperature regulation with a step of 2 ° С;

- Daily automatic switching of heating modes - from 3 to 8;

- Prevent system freezing. Maintaining a minimum level of heating of the coolant during the absence of residents;

- For some models, remote GPS control of heating operation is provided.

For the correct operation of automatic systems for gas boilers, the correct connection must be made. To do this, the equipment operating instructions contain a detailed description to which boiler contacts one or another module must be connected.

The cost of programmers depends on their functionality and performance. On average, it ranges from 7,000 to 14,000 rubles.

To increase the efficiency of the automation in the heating system, it is recommended to install thermostats on radiators. This will make it possible to regulate the thermal regime in a specific heating section.

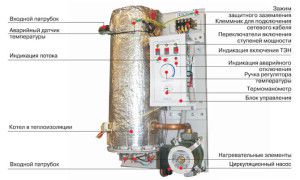

Electric heating boilers

Do you need automation for electric heating boilers? The specificity of their work implies the installation of water temperature sensors, its pressure, as well as automatic shutdown when the voltage in the network is exceeded.

For them, installation of almost all weather-dependent automation of heating systems is possible. However, when installing electric boilers, there are special requirements for their connection to the mains. For this, another type of device is used - an RCD (residual current device). This element is optional when installing gas equipment.

Optimization of energy costs is possible when installing automation for electric heating boilers. It is designed to regulate the power depending on the selected parameters. The main difference from gas models is the less inertia of the system - mode switching occurs quickly. In this case, the functions will be the same as for the automation of gas heating boilers.

For old electric boilers, there is a special automation that is adapted to their design. Examples of such devices are Terneo RK and Auratron 2005TXPlus. Their average cost is 5-7 thousand rubles.

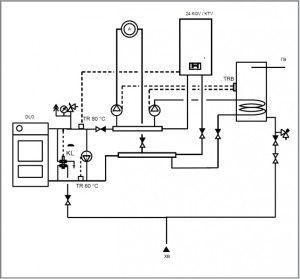

Heating pump automation

In large heating systems, several pumps are often provided. During their operation, it is difficult to achieve full power synchronization. Even a small deviation can lead to the creation of excessive hydraulic pressure in a certain section of the pipeline. The way out of this situation is automation for the heating circulation pump.

Such devices are necessary not only to synchronize the operation of the system, but are also designed to control the pump in the mixing unit of the water heated floor. The advantages of using automation for a heating circulation pump are as follows:

- Stabilization of the equipment operating modes leads to an increase in the time of their maintenance-free operation;

- Reducing energy consumption;

- Reduced noise levels. This is especially true for mixing units installed indoors.

Despite a number of advantages, the use of automatic complexes in private heating can only be relevant if there are 2 or more pumps. Often, the installation of such devices is performed for heat-conducting utilities or industrial networks.

How to choose the right automation for heating with gas and electric boilers, pumps? First of all, you need to know the required parameters - the thermal mode of operation, the required degree of regulation of the heating agent heating, the expected economic effect. For this, all heating characteristics should be calculated, including the costs of the energy carrier. Such calculations can be done using special programs.

As an example, you can see the overview of Galan heating automation: