It is customary to call stone or mineral wool all heaters that are made from solid natural material - basalt, gabbro, volcanic slag, sand, metallurgical slag, diabase, limestone, dolomite, plus many related components. But when using this material in construction work, it is necessary to take into account their properties, otherwise, instead of a water-repellent layer, you can get the opposite - a hygroscopic substance that will quickly lose its shape.

- general information

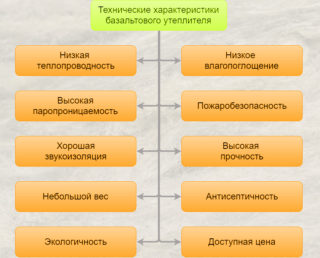

- Basalt insulation characteristics

- Thermal conductivity

- Ability to absorb moisture

- Vapor permeability

- Fire resistance

- Density

- Soundproofing

- Where is mineral wool used

- Pros and cons of basalt thermal insulation

- Varieties of insulation

- By fiber type

- Foil

- By strength

- Installation methods

- How to cut the insulation

general information

The very first experience of obtaining basalt fiber belongs to the large English industrialist Edward Perry, who noticed that during the eruption of lava from a volcano, it freezes in the air and turns into the finest threads. The businessman decided to try to reproduce the process in the shop. The experiment turned out to be unsuccessful, since the technology did not provide for the protection of the respiratory organs of the workers, who several times inhaled the finely dispersed substance and fell ill.

The next time, the fiber was already received in Germany, deciding to improve the process, taking into account Perry's mistakes. The fiber was produced in an enclosed area where people did not have access. As a result, we got a basalt insulation, the characteristics of which coincided with the expected ones.

Basalt insulation characteristics

Despite the similarity of various materials, which are called mineral wool, they can have completely different structures and purposes. The highest quality material is considered to be the one that has a balanced amount of acidic elements in the composition. This makes the stone wool waterproof and therefore durable.

The second important element of basalt insulation is the fiber binder. It can be:

- synthetic origin;

- bituminous;

- multicomponent;

- bentonite.

At the moment, the most used is phenol-formaldehyde resin, although foreign manufacturers no longer produce mineral wool with phenol, since this substance is a carcinogen. At normal and low temperatures, it is not harmful, since it does not evaporate, but at high temperatures or in a fire it can cause poisoning.

Thermal conductivity

The thermal conductivity of stone wool is very low, so in the winter season the cold does not pass through it, and in the summer the material does not let the heat into the room. Such regulation occurs due to the porous-fibrous structure in which air masses are retained. While gas exchange takes place, they have time to heat up or cool down.

Depending on the density with which the fibers are pressed into plates, the degree of thermal conductivity can change up or down. It also affects the position of the fibers - how they are located horizontally and vertically.The more intersections, the less mineral wool conducts air masses - hot or cold.

Ability to absorb moisture

If we compare basalt wool and slag wool, the moisture capacity of these two materials will be different. Where there is high humidity, slag wool should not be used. Moreover, it is impossible to wrap iron structures with it, since they will quickly become covered with a layer of rust due to the hygroscopicity of slag.

Cotton wool from diabase or dolomite in terms of moisture resistance can compete with basalt. These materials are as dry as basalt. Glass wool tends to accumulate moisture, so it is used only for interior work.

Vapor permeability

Air circulates inside the stone insulation, so water molecules are not retained in the room. The pores between the fibers are open and do not interfere with moisture evaporation.

Fire resistance

In nature, basalt rocks melt at temperatures above 1000 degrees. It is impossible to achieve such a value in domestic conditions, therefore, in the worst case, the material will be sintered and lose its shape, but this requires a very strong fire with the use of chemical fuel.

Stone wool is non-combustible and does not support combustion. When the temperature drops in a fire, the fibers immediately freeze. The only harm it can cause to health is the release of a binder and inhalation of it by a person.

Density

The density of basalt wool depends on the amount of fibers used in the production. Different brands produce materials that, in terms of their density, are intended for specific work - internal, external, for pouring into concrete. The higher the density, the more loads the basalt wool can withstand. For example, not every brand can be laid under a concrete floor, since it will lose its shape under the weight of the cement mortar.

The densest material is produced in slabs. Basalt slabs for insulation of external walls and floors are very hard and can withstand high compressive loads.

Soundproofing

Basalt insulation is often used as a sound insulating material. Chaotically located fibers create a barrier to sound waves. There are separate brands that are designed exclusively for soundproofing rooms.

Where is mineral wool used

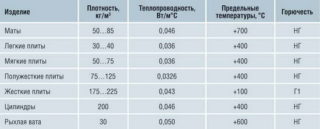

Depending on the density, stone wool is used for different jobs. There are grades of material:

- P-75 is the lightest. The weight of a cubic meter of material is 75 kg. It is used for horizontal surfaces with a minimum load, since under pressure the cotton wool shrinks and loses some of its thermal insulation properties. Can be used to insulate an attic or roof. Suitable for siding or other rigid facade cladding.

- P-125. The weight of a cubic meter is 125 kg. Suitable for interior walls, doors and ceilings, which has a positive effect on the noise level.

- P-175. High density material that looks like a wooden board. Suitable for thermal insulation of reinforced concrete structures, intermediate floors with increased load. Dense boards are suitable for plastering, as liquid mixtures are well applied to a rigid base.

- P-200 is the toughest material in this series, so there is not enough air in it to combine sound insulating properties and strength. This grade is used for pouring into concrete. At the same time, it does not wrinkle and does not lose thermal conductivity.

The first two grades are produced in slabs and rolls. The rest - the most dense - only in slabs. Also, the products differ in thickness: for normal conditions, a layer of 50 mm is used, in extreme conditions - 100 mm.

Cylindrical structures are also produced for thermal insulation of pipelines located above the level of freezing of the soil, chimneys, water pipelines. Such products have special locks in the form of cutouts so that the plate is in good contact with the pipe.

Pros and cons of basalt thermal insulation

Basalt stone wool is a universal insulation in all respects, when compared with other types - glass wool, slag. If you insulate a house with basalt fiber, you can count on the following advantages:

- Long service life - up to 50 years according to the manufacturers.

- The material does not shrink, therefore it does not lose its useful properties during its service. Provided that it is selected correctly and technologically correctly laid.

- The room does not accumulate water vapor and condensation, so mold is unlikely to form.

- Saving electricity and heat carriers due to the preservation of heat in winter. In summer, less often you will have to turn on the air conditioner, since the walls keep the cool.

The main obstacle for people is the myth of the carcinogenicity of basalt wool, that is, its ability to cause cancer in humans. The International Agency for Research on Cancer in the United States has conducted a number of studies, based on which mineral wool was put on a par with caffeine and tea. In their opinion, vegetables in brine are more harmful, since they are an order of magnitude higher, that is, they are more dangerous. As for binders, there are no more than 4% of them in the composition, therefore they are not capable of causing any disease.

Confirmed the data of research in Germany - the country in which environmental laws are the most stringent. Even there, mineral wool was classified as a substance whose carcinogenicity could not be proved.

Varieties of insulation

All types of mineral wool can be distinguished by the type of fiber - its thickness, length and physical properties. For example, the thickness of the fiber in glass wool is from 5 to 15 microns. With all the positive qualities, thin glass threads have a high degree of fragility, can get into the lungs and cause health problems. When working with this material, you need to wear a protective suit, a respirator and goggles so that the threads do not penetrate the skin - this causes redness and itching.

By fiber type

The thickness of the stone wool fibers is from 3 to 5 microns, their length is up to 16 mm. This allows it to be pressed into solid slabs with a minimum amount of air inside. Basalt insulation fibers do not prick and do not damage the respiratory system. You can work with them without protective devices.

Slag wool contains fibers up to 16 mm long and 5 to 12 microns thick. They are just as prickly as glass wool, so workers need to use protection.

Foil

Available in regular stone wool and foil to reflect more heat into the room. For bonding, aluminum foil is used, sanded to such an extent that it can reflect the greatest amount of radiant energy.

A layer of aluminum can be glued or sprayed onto the basalt insulation. Foil enhances such properties of mineral wool as:

- thermal conductivity;

- waterproofing.

Useful properties of materials with a low degree of moisture protection, for example, slag wool, can be improved using foiling technology.

By strength

Strength is based on the properties of the raw material used for the production of mineral wool. The most durable is basalt - a heavy volcanic rock, followed by wastes of metallurgical blast furnaces, then glass.

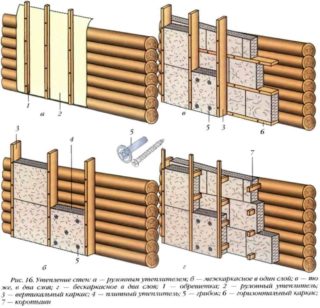

Installation methods

There are three ways to mount stone wool or any other insulation. Two of them involve the use of drywall, the third - just into the wall.

For the method without drywall, you need:

- the estimated amount of insulation;

- the base for the construction of the profile;

- staples for the convenience of attaching cotton wool;

- tape measure and scissors.

Operating procedure:

- Fix the brackets on the wall every 50 cm. Mineral wool insulation will be put on them.

- Unwind the rolls and cut with scissors to the height of the walls. Can be taken with a margin of 3 cm in case of deformation.

- Put the pieces on staples so that the layers overlap.

- Attach the profiles and press the material against the wall.

In some cases, the cotton wool is covered with a vapor-permeable film. It is also good to keep particles away from the eyes and skin.

Second way:

- Knock down a drywall profile so that its width is not less than the thickness of the mineral wool.

- Screw the profile to the wall and insert the roll insulation into it. Sometimes they make square holes in the profile and put mineral wool slabs there.

- Sew up the cotton wool with sheets of drywall.

If you do not plan to make plasterboard walls, you can use denser plates and glue them to the wall, having previously cleaned them of plaster residues. There are special adhesives for this. In the same way, basalt wool is mounted on ceilings or roofs, even if the frame is previously constructed.

The most popular way to sew up a wall with insulation is to attach the plates with dowels, after placing a square plate of a dense material, such as plastic or wood, under the head.

To lay the mineral wool in the floor under the concrete screed, logs are used - floors made of wood or polymer materials, between which insulation is laid. In this case, dense slabs are used that can withstand the load when pouring concrete mixture with a large weight from above.

How to cut the insulation

When cutting mineral wool insulation, there is a risk of fiber damage, which will affect the thermal insulation properties. The most suitable tool is an assembly knife, but it has a short blade - it will not cut thick slabs.

A Serrated Bread Cutter can be found in the kitchen. Before work, it must be sharpened.

In building supermarkets, you can find special knives made of stainless steel or carbon fiber, which are designed for cutting insulation. A hacksaw for wood is a cheap alternative.