Mineral wool of domestic or imported production is used in the construction of buildings, the production of buses, trains, boats, baths are insulated with cotton wool and much more. Mineral wool and basalt belong to the category of building insulation obtained from inorganic substances. But in everyday life, mineral wool is usually referred to as glass wool.

Features of basalt wool

Basalt is one of the hardest stones; monuments were made from it in Ancient Egypt. The most common basalt product in construction is cotton wool. At first glance, its production is a complex process. To obtain it, the molten stone is split into long and thin fibers under the influence of high temperature.

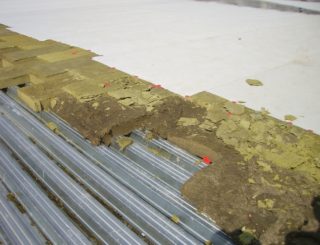

The substance has a porous structure, saturated with oxygen, non-combustible, vapor permeable, but low hygroscopic - it almost does not absorb moisture. Basalt mineral wool is easy to cut, but retains its shape and withstands light loads. This determines its widespread use. It is indispensable for ventilated facades. Being exposed to cold, moisture, snow, negative or high temperatures all year round, the insulation does not collapse and performs its heat-saving function. However, it is not covered with membranes and films.

Basalt wool is used in building structures in almost all areas outside and inside the building. Due to the low hygroscopicity, it is beneficial for her to insulate baths, saunas. It is mounted on ventilated facades as part of sandwich panels. They are used to insulate pipelines operating in various conditions - from -120 degrees to +700 degrees Celsius. Due to its fire resistance and lightness, the material is used to isolate structures from heating elements - chimneys of stoves and fireplaces, to separate the firebox from the main masonry.

Advantages and disadvantages of basalt wool insulation

This material has more pluses than minuses. This is due to the properties of the original material - basalt is one of the hardest stones, difficult to work with. In the form of cotton wool, it retains its properties. It emits much less dust than glass wool due to the stronger fibers. Material advantages:

- Low thermal conductivity - a 10 cm thick layer of wool is similar in heat saving to a 160 cm brick wall.

- Fire resistance - withstands direct fire, temperatures over 1100 degrees Celsius.

- Low weight in comparison with other heaters, for example, expanded clay - it is easy to lift the slab on your own, without the help of equipment.

- Convenient installation - the material can even be attached to the ceiling.

- Does not support the growth of bacteria, fungi, insects.

The material is easy to install, it can even be attached to the ceiling - Not damaged by rodents.

- Suitable for floor, wall and ceiling insulation.

- Environmental friendliness - does not emit harmful substances.

- Chemically resistant - does not react with acids and alkalis, solvents.

- Easily assembled with your own hands in the attic, apartment, office.

- Does not corrode even in contact with metal.

- Excellent sound absorption and sound insulation.

Despite the wide range of applications, fire resistance, sound insulation, basalt wool also has disadvantages:

- High price.

- Less durable than expanded polystyrene foam.

- It is vapor-permeable, therefore it accumulates moisture over time.

- It emits a small amount of dust when cutting and laying, therefore a respirator must be worn.

Mineral insulation board is stiffer than cotton wool. Minvata can be dispensed in packages or in bulk. According to their characteristics, they are the same, but if you need to insulate the wall, a plate is preferable for laying.

Basalt-based wool is similar in many ways to other heat insulators made of inorganic materials. But it will differ from similar materials in the following aspects:

- It is easier to install than glass wool. Fiberglass has to be placed in a respirator, a tight suit, since the fibers can get into the respiratory tract, on the skin, and cause irritation. When working with a basalt analogue, such measures are not necessary.

- Basalt wool can withstand heating up to 1100 degrees, when heated to 700 degrees, it does not change its properties for a long time, and glass wool begins to change its structure already at 300 degrees.

- Insulation is more environmentally friendly, emits less harmful substances.

- The cost is higher than that of glass counterparts.

Features of mineral wool

This category of building materials includes: slag wool obtained from waste of the metallurgical industry, glass wool from molten quartz sand and stone wool, including basalt. All these species are resistant to fire; it will take several hundred degrees to ignite them. For comparison, the popular polystyrene foam insulation smolders already at 85 degrees. Cotton wool has excellent sound insulation. Stone wool absorbs moisture least of all, glass wool requires moisture insulation, otherwise, having absorbed water, it almost completely loses its thermal insulation properties.

Minvats are good heat insulators, they are used in various parts of buildings and vehicles, including ships. They are easy to process, have a low density and light weight, therefore they are convenient for transportation. A small layer of such insulation is similar in terms of its thermal insulation characteristics (but not strength) to a brick wall.

Stone wool, subject to the technological process, is not harmful to health. Glass wool is more commonly used in industrial buildings as it is more harmful. Its fibers break easily, getting into the respiratory tract or on the skin, causing irritation.

Which material is better

Which variety to choose depends on the specific task assigned to the insulation. Glass wool is cheap, but crumbles strongly, causes allergies, so it is not used in residential premises. During the construction of business centers in Moscow and other cities, mineral wool is used to insulate facades, walls and other structural elements. Builders choose basalt insulation as it is more resistant to weather conditions.

The main difference between basalt mineral wool is short and thick fibers in its structure, which makes the material more resistant to stress. Due to its low moisture absorption, it is suitable for rooms with high humidity - showers, saunas, baths. Despite the presence of phenol in the composition, it is considered environmentally friendly, therefore it is used in residential premises and offices for wall insulation, sound insulation of partitions, roof insulation.

Basalt wool has a higher mechanical strength, does not crumble. It is preferable to use it for doors as the most durable, resistant to dynamic loads. For the rest of the characteristics of fire safety, sound and thermal insulation, other types of mineral wool are similar.