A sharp drop in temperature in winter can lead to the formation of an ice block in the external sewage system. It is very difficult to warm it up, therefore, experts advise using insulation for sewer pipes when installing communications. When choosing a material, take into account its characteristics, service life and installation features. Thermal insulation of engineering networks in a private house occurs during the construction phase. The process does not require special knowledge, so you can do it yourself.

Requirements for heaters

When choosing a heat insulator, it must be borne in mind that it will be under the negative influence of the environment for a long time. So that during operation the material does not lose its performance characteristics, it must meet certain requirements:

- Moisture Resistant - The material will be regularly exposed to water entering the soil.

- Thermal conductivity coefficient - a low value of the parameter indicates the reliability of the insulation.

- Resistance to loads - the insulation is subjected to pressure and mechanical action of the soil, while it should not tear, be covered with cracks.

- Ease of installation - the material is often laid by hand, the work should be done quickly, without the use of special tools.

- Chemical inertness - the heat insulator is used in soil, which is an aggressive environment. Chemicals enter the ground that increase the acid and alkaline levels.

- Non-combustibility - the criterion increases the safety of the sewer system.

- Democratic cost - the cost of insulation should be available to a wide range of buyers.

A good heat insulator will protect the pipes from frost. Before buying, it is worth examining the product, checking the certificates and the appearance of the products. Mineral wool insulation should have a dense fibrous structure, foamed polyethylene air cells of the same size. The material should not be torn or damaged by slight impact on it.

Types of heaters for sewer pipes

There is a large selection of materials on the building products market that meet the listed criteria. They can be divided into several large groups: bulk, roll, shell. Each insulation has characteristic installation features: roll insulation must be cut into separate sheets and fastened with clamps, the shell is sealed with tape.

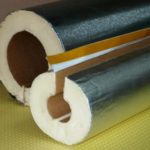

Mineral wool

Fiber insulation is made by processing rocks or slags. The cheapest option is glass wool, which is made from broken glass. Stone or basalt wool is resistant to high and low temperatures, its thermal conductivity is only 0.035-0.039 W / m * K. The material is characterized by low hygroscopicity, but when it is in dampness it accumulates moisture. Mineral insulation is not afraid of mold and mildew, does not burn, and is resistant to chemicals.

The use of foil-coated mineral wool partially protects the fibers from getting wet and prolongs the life of the material. The heat insulator is available in rolls and molded cylinders. Material thickness 50-150 mm. Rigid cylinders covered with foil or fiberglass are the most convenient option for thermal insulation. They are put on the pipe through a special cut. Once sealed, the fibers will be protected from moisture. Installation takes place in a short time.

Cons of insulation:

- when wet, heat loss increases;

- slag wool promotes the formation of corrosion on metal pipes;

- over the years, the material cakes, cold bridges are formed.

The material is affordable and easy to use, therefore it is popular as thermal insulation for sewers.

Foamed polyethylene

The disadvantages of the material include:

- destruction under the influence of ultraviolet radiation;

- the need to wind several layers due to the small thickness;

- low load resistance.

Foamed polyethylene is recommended for insulating sewers located in unheated rooms.

Expanded polystyrene

Styrofoam for pipe insulation is offered in the form of a shell. The product consists of two halves with a lock connection. The material has high rigidity and density.

Its diameter is 17 mm and more. For pipes with a large cross-section, a shell is made, consisting of 4-8 elements. The positive characteristics of the heat insulator:

- low thermal conductivity;

- affordable cost;

- moisture resistance;

- easy installation;

- biological and chemical inertness;

- service life up to 50 years.

Penoplex has similar properties. Heaters are made from the same raw materials, but penoplex is stronger and denser than foam. It is resistant to deformation and will last a long time. The disadvantage of insulation is sensitivity to mechanical stress. For reinforcement, the cylinders are covered with fiberglass outside, protected with plastic wrap. Also, the disadvantages include the hardness of the shell, it can only be used on flat areas.

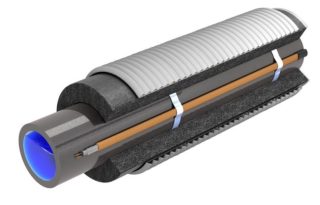

Polyurethane foam

According to its technical characteristics, foam polyurethane insulation is considered one of the best. It has the lowest thermal conductivity coefficient, does not absorb moisture, and is resistant to aggressive media and biological effects. Polyurethane foam can be used under any climatic conditions and can withstand significant loads.

It is applied to pipes in liquid form using a special installation or using a molding shell. Semi-cylinders are connected by transverse and longitudinal locks. To further protect the shell from the negative effects of the soil, it is covered with polyethylene or placed in a galvanized casing.

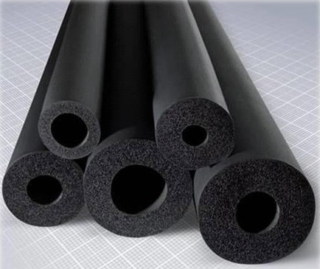

Rubber

Foamed rubber is a new generation of heaters with excellent heat-shielding characteristics. The elastic material is marketed in rolls or cylinders. It is biologically sustainable and environmentally friendly.

The raw material for it is natural and combined rubber. Elastomer with a porous structure, thanks to its flexibility, adheres tightly to pipes, providing reliable thermal insulation.

The thickness of the insulation in the form of tubes is 6-32 mm, it is focused on products with a section of 6-114 mm. There are two ways to fix the insulation on the sewer:

- welded seam;

- sticky strip at the junction of the incision.

The rubber is durable, does not support combustion, and can be operated at -200 ° C. The disadvantage of a heat insulator is its high cost.

Expanded clay

The easiest way to protect communications from freezing in winter is to fill them with expanded clay. It is a porous building material obtained by firing clay.The thermal insulation properties of natural backfill are often used when laying utility networks. One of the important advantages is the low price of expanded clay. The disadvantage of this method is the sensitivity of the material to moisture. After getting wet, it loses its properties. The backfill insulation in the trench is isolated from water using special membranes. The canvas spreads to the bottom, closes the pit walls and expanded clay with an overlap on top. Sewerage insulation works are carried out in dry weather.

Heat insulating paint

The special energy-saving paint composition includes microspheres of perlite, ceramics or foam glass. In addition to the vacuum spheres, there is an acrylic or latex binder. Manufacturers claim that a 2-4 mm layer of paint replaces 50 mm of mineral wool. The compound is applied to the surface of the pipes, forming an elastic waterproof coating. It is resistant to temperature extremes and lasts 20-40 years. The paint is applied by roller or spray. In case of damage, the layer is easily restored.

DIY thermal insulation installation steps

Depending on the chosen method, the thermal insulation process takes place simultaneously with the installation of the pipeline or after its laying. Work begins with the preparation of a trench with a depth of 50 cm and more. Before insulating plastic sewer pipes in the ground, it is necessary to pour a sand cushion. Insulation laying technology depends on its shape. Products can be divided into several groups:

- Rolled - mineral wool in mats is mounted in several stages. The pipe is preliminarily pasted over with coils of adhesive tape in a spiral. Then it is wrapped with insulation, adjacent canvases are laid with an overlap of 15-20 cm. From above, cotton wool is fastened with clamps and tape. Experts recommend covering the insulation with roofing felt for waterproofing.

- Shell - rigid components have locks for fixing, but for tightness, the joints are coated with glue. If a detachable connection is required, improvised materials are used to fasten the parts - wire, metal tapes. Products coated with aluminum foil are glued with foil tape.

- Mineral wool cylinders have a longitudinal cut to fit over the pipe. When laying basalt or glass wool, the components are tightly pressed against each other. The cylinders are fixed with plastic or metal clamps. If the insulation is covered with foil on the outside, use aluminum tape.

- Foamed polyethylene cylinders are put on after the final installation of the sewage system. They can be with or without a cut. In the second case, the material is cut independently. All joints of the insulation must be glued with construction tape. Rubber cylinders have adhesive strips covered with paper at the cut. After installation, the strips are removed, the edges of the insulation are squeezed together.

Insulation of pipes with any material should be carried out in dry weather. This will avoid getting the metal communications and heat insulator wet.

Features of insulation of sewer pipes in a private house

An external communication network connects the internal sewerage system of a residential building with a place where waste water is received (septic tank, drain pit). To protect it from freezing, you must follow the rules for installing engineering systems:

- The laying of the sewer pipeline is carried out at a depth below the freezing point of the soil in the region.

- An important factor is the observance of the angle of inclination of 15-20 mm per 1 running meter. The effluent should move to the septic tank without delay.

- Thermal insulation of pipes starts from the place where the sewer is removed from the house. A hole is made in the foundation or in the lower part of the wall that is larger than the diameter of the pipeline. The free space is filled with insulation and sealed.

- Installation of external sewerage is carried out with pipes with a cross section of at least 110 mm. The material for them is cast iron, asbestos cement, ceramics. The most common option is plastic. PVC sewage system is resistant to corrosion, durable, not prone to blockages, easy to install.

- When installing a sewer line, it is necessary to minimize the number of turns.

If it is impossible to deepen the pipes that drain the drains into the ground, combined insulation is used. The system includes a heating cable that provides a positive temperature of the utility network. A layer of thermal insulation is mounted on top of the electrical heating element to avoid energy losses.

Thermal insulation of engineering systems in a private house eliminates problems with their operation in the winter. When installing an external sewage system, it is important to follow the installation rules and choose the right type of insulation.

the sewage system never freezes if the slope is correct