How can you reduce the fixed costs of maintaining a comfortable temperature in your home? There are many truly effective ways, from installing boilers with the highest possible efficiency to installing alternative heat sources. But one of the most productive is a heat accumulator for heating systems.

Buffer tanks for heating

In autonomous heating schemes, the constant operation of the boiler is almost always provided. This entails an increase in energy costs and a decrease in the service life of expensive equipment due to its wear and tear. The heating accumulator is designed to optimize the operation of the entire system.

Purpose of buffer tanks

It is a container inside which the heating main runs. The heat transferred from the pipes to the water in the tank heats it up. When the boiler is turned off, the temperature of the coolant decreases and the reverse process begins - heat energy comes from the water in the tank through the walls of the pipes to the coolant. In this way, heat accumulators in heating systems allow maintaining a comfortable heating level for a long time after the boiler is stopped.

Why are storage tanks for heating not installed in each autonomous system? There are a number of specific factors that must be taken into account before installing them:

- Volume... To maintain the temperature in a house with an area of 120 m² for 10-12 hours, a container with a volume of 1.5-1.8 m³ is required. It is not always possible to place such a water accumulator for heating in the system;

- The cost... Average price of a 750 liter buffer tank. is about 90 thousand rubles. In fact, it turns out that the heat accumulator in the heating system will be the most expensive element.

The latter is the main reason not to install a thermal buffer capacity. But if you make approximate calculations of efficiency, it turns out that heating with a heat accumulator requires 10-15% less energy carrier (gas, firewood, coal, etc.) compared to the traditional scheme.

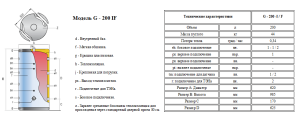

The diameter of the connected tank connections must match the dimensions of the system piping. Otherwise, there will be excessive hydraulic resistance.

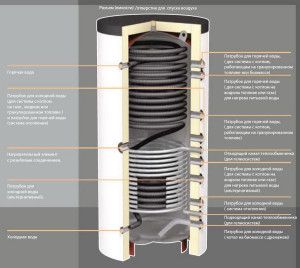

Heat accumulator design

Making your own battery for heating at home will not bring the desired result. This is due to the specifics of the design and the materials used. It is almost impossible to make such a tank out of improvised means without the use of special equipment.

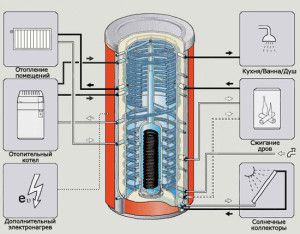

In addition to the main function of heat storage, most manufacturers are trying to improve the design so that the heating system with a heat accumulator can be used in other areas of the life support of a private house:

- Hot water supply. The water heated in the tank can be used as hot water supply - for taking a shower, washing dishes, etc. The main thing is that the container is indirectly heated;

- A switching element for connecting alternative heat sources - solar systems, heat pumps. This heating scheme with a heat accumulator allows you to heat water in it using the conditionally free energy of the sun. As a result - a decrease in operating costs;

- Connection of several boilers in one circuit. Thus, it is possible to organize heating with a solid fuel and gas boiler.

To reduce heat losses in heat accumulators in heating systems, two walls are provided - an outer and an inner one. The space between them is filled with insulation, most often with basalt wool. In addition, most models have an additional heat source - an electric heating element. It allows you to maintain the temperature of the water in the storage tanks for heating at the desired level. This also makes it possible to use the container even when the boiler is not working as an ordinary electric boiler.

When using alternative heat sources, it is recommended to purchase a tank with two piping circuits.

Calculation of the heating accumulator

In practice, it is first necessary to calculate the optimal volume of water storage for heating. There is a misconception that the higher this indicator, the better. But when the critical volume is exceeded, the rate of water heating in the tank is significantly reduced and it simply does not have time to reach the required temperature. This is especially true for systems with a maximum heating agent heating up to 60 ° C (low-temperature heating mode).

The main condition for the functioning of heating with a heat accumulator is the maximum increase in the operation of the system when the boiler is off. Therefore, the main indicator when choosing a buffer tank according to its characteristics is the time it takes for the water heated in it to cool down.

The most common mistakes when calculating a heating system with a heat accumulator:

- Only the rated power of the boiler is taken into account... Allegedly, the ratio is sufficient: 1 kW of energy requires from 25 to 50 liters of capacity. But how, in this case, take into account the cooling time of the coolant?;

- Location in the system... The highest efficiency is achieved only for a heating circuit with a heat accumulator, which is installed immediately after the boiler. Then the heat transfer will be optimal.

To perform the calculation, you will need to know the boiler power and the thermal mode of the system. Let's assume that the heater generates 22 kW / h. In this case, the operating mode is 70/40 (70-40 = 30 ° C). In this case, the optimal volume of the heat accumulator in the heating system will be:

(22 * 3600) / (4.187 * 30) = 633 kg or 0.633 m³

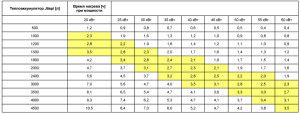

Now it remains to calculate the time for heating the water in the container. Alas, there is no universal formula for this. There is a great dependence on the performance characteristics of a particular model of the accumulator for the heating system. But this data can be taken from the instructions or on the manufacturer's website. As an example, we can consider the dependence of the heating rate of the Wirbel storage tank of various capacities on the boiler power.

Taking into account all these indicators, it is possible to accurately calculate the approximate volume of the heat accumulator in a particular heating system. More accurate calculations are made using special software systems that take into account the rate of circulation of the coolant, heat losses and possible changes in heating operating modes.

Any calculation scheme should take into account the recommendations of manufacturers and the requirements for the operation of an autonomous heating system.

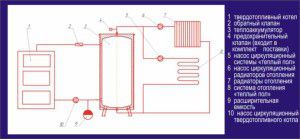

Installing a heat accumulator

The correct installation of the water accumulator in heating depends not only on the heating time of the water in it, but also on the efficiency of the entire system. The determining factor is the way of circulation of the coolant - gravitational or with the help of a pump. In the first case, storage tanks are installed in the heating up to the upper expansion tank, as close as possible to the boiler.

It should be borne in mind that the speed of movement of the coolant will be slightly reduced. This is due to the increase in the length of the booster tube due to the insertion of an additional section located in the tank.For a gravity system, it is recommended to reduce the estimated volume of the tank by 10-15%.

The place of installation in a forced circulation system is not regulated. It is important that the level of heating of the coolant in the heating pipes with a heat accumulator is maximum. Accordingly, the container should be located close to the boiler in compliance with the following conditions:

- The tank is placed after the safety group;

- The temperature in the room where the container is located should be from 10 to 35 ° С;

- Free access to all branch pipes of the structure for repair and maintenance work;

- Possibility to connect both main and return pipes.

Most often, in heating systems with a heat storage tank, it is installed directly in the boiler room. Installation above the boiler level is not recommended.

In addition to these conditions, there may be additional ones regulated by the manufacturer. They must be taken into account not only when choosing a place for installing the tank, but for regulating the boiler power.

When installing a heat accumulator for heating systems with electric heating elements, it is recommended to additionally mount a multi-tariff electricity meter. Substantial savings can then be achieved by including electric tank heating at night.

The video material clearly shows the principle of operation of a heat accumulator in the heating system of a private house: