For the efficient operation of the heating system, several conditions must be met - to choose the right components and make a calculation. Efficiency and uniform heat distribution depend on the correct calculation of the parameters of the system. How to make a hydraulic calculation of a heating system - examples, programs will help you perform these calculations.

Purpose of hydraulic calculation of heating

During the operation of any heat supply system, hydraulic resistance inevitably arises when the coolant moves. To take this parameter into account, a hydraulic calculation of a two-pipe heating system is required. Its essence lies in the correct choice of system components, taking into account their performance.

In fact, the hydraulic calculation of water heating systems is a complex procedure, during which all the subtleties and nuances are taken into account. At the first stage, you should decide on the required heating power, choose the optimal piping layout, as well as the thermal mode of operation. Based on these data, a hydraulic calculation of the heating system is made in Excel or a specialized program. The result of the calculations should be the following parameters of water heat supply:

- Optimum pipeline diameter... Based on this, you can find out their throughput, heat losses. Taking into account the choice of the material of manufacture, the resistance of water against the inner surface of the line will be known;

- Losses of pressure and head in certain areas of the system... An example of a hydraulic calculation of a heating system will allow you to think in advance of mechanisms for their compensation;

- Water consumption;

- Required power of pumping equipment... Relevant for closed systems with forced circulation.

At first glance, the hydraulic resistance of the heating system is complex. However, it is enough to delve into the essence of the calculations a little and then you can do them yourself.

For heat supply of a small house or apartment, it is also recommended to calculate the hydraulic resistance of the heating system.

The procedure for calculating the hydraulic parameters of heating

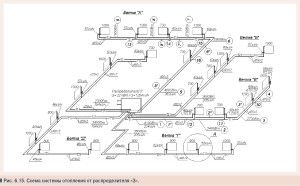

At the first stage of calculating the parameters of the heating system, a preliminary diagram should be drawn up, which indicates the location of all components. Thus, the total length of the lines is determined, the number of radiators, the volume of water, as well as the characteristics of the heating devices are calculated.

How to make a hydraulic calculation of heating without having experience with such calculations? It should be remembered that it is important to choose the right pipe diameter for autonomous heating. It is from the performance of this stage that the calculations should begin.

It is best to make a heating scheme on an already finished house plan. This will allow you to correctly calculate the consumption of material and determine its amount for the arrangement of the system.

Determination of the optimal pipe diameter

The most simplified hydraulic calculation of the heating system includes only the calculation of the cross-section of the pipelines. Often, when designing small systems, they do without it. To do this, take the following parameters of pipe diameters, depending on the type of heat supply:

- Open circuit with gravitational circulation... Pipes with a diameter of 30 to 40 mm. Such a large section is necessary to reduce losses during friction of water against the inner surface of the lines;

- Closed system with forced circulation... The cross-section of pipelines varies from 8 to 24 mm. The smaller it is, the more pressure will be in the system and, accordingly, the total volume of the coolant will decrease. But this will increase hydraulic losses.

If there is a specialized program for the hydraulic calculation of the heating system, it is enough to fill in the data on the technical characteristics of the boiler and transfer the heating scheme. The software package will determine the optimum pipe diameter.

The data obtained can be checked independently. The procedure for performing a hydraulic calculation of a two-pipe heating system manually when calculating the diameter of pipelines is to calculate the following parameters:

- V - the speed of water movement. It should be in the range from 0.3 to 0.6 m / s. Determined by the performance of pumping equipment;

- Q - heat flow. This is the ratio of the amount of heat passing over a certain period of time - 1 second;

- G - water consumption. Measured in kg / hour. Directly depends on the diameter of the pipeline.

In the future, to perform the hydraulic calculation of hot water heating systems, you will need to know the total volume of the heated room - m³. Let's assume that this value for one room is 50 m³. Knowing the power of the heating boiler (24 kW), we calculate the final heat flow:

Q = 50/24 = 2.083 kW

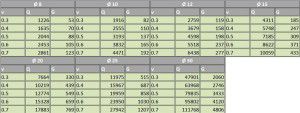

Then, to select the optimal pipe diameter, you need to use the table data compiled when performing the hydraulic calculation of the heating system in Excel.

In this case, the optimal inner pipe diameter for a specific section of the system is 10 mm.

In the future, to perform an example of a hydraulic calculation of a heating system, you can find out the approximate water flow, which will whistle from the diameter of the pipe.

Manufacturers of polymer pipes indicate the outer diameter. Therefore, for the correct calculation of the hydraulic resistance of the heating system, two wall thicknesses of the mains should be subtracted.

Consideration of local resistances in the line

An equally important step is the calculation of the hydraulic resistance of the heating system at each section of the line. For this, the entire heat supply scheme is conventionally divided into several zones. It is best to do the calculations for every room in the house.

As the initial data for entering into the program for the hydraulic calculation of the heating system, the following values will be needed:

- The length of the pipe at the site, lm;

- Line diameter. The calculation procedure is described above;

- The required speed of the coolant. It also depends on the diameter of the pipe and the power of the circulation pump;

- Reference data typical for each type of material of manufacture - coefficient of friction (λ), friction loss (ΔР);

- The density of water at a temperature of + 80 ° C will be 971.8 kg / m³.

Knowing these data, you can make a simplified hydraulic calculation of the heating system. The result of such calculations can be seen in the table.

When carrying out this work, it must be remembered that the smaller the selected heating section, the more accurate the data of the general parameters of the system will be. Since it will be difficult to make a hydraulic calculation of heat supply the first time, it is recommended to carry out a number of calculations for a certain interval of the pipeline. It is desirable that it contains as few additional devices as possible - radiators, valves, etc.

To check the hydraulic calculation of a two-pipe heating system, you need to perform it in several different programs or additionally manually by yourself.

Overview of programs for hydraulic calculations

In fact, any hydraulic calculation of water heat supply systems is a complex engineering task. To solve it, a number of software packages have been developed that simplify the implementation of this procedure.

You can try to make a hydraulic calculation of the heating system in the Excel shell, using ready-made formulas. But at the same time, the following problems may arise:

- Big error. In most cases, one-pipe or two-pipe schemes are taken as an example of a hydraulic calculation for a heating system. Finding such calculations for the collector is problematic;

- For the correct accounting of the hydraulic resistance of the pipeline, reference data are required, which are not available in the form. They need to be searched for and entered additionally.

Taking these factors into account, experts recommend using calculation programs. Most of them are paid, but some have a limited demo version.

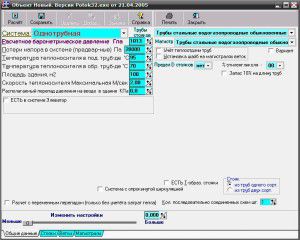

Oventrop CO

The simplest and most intuitive program for the hydraulic calculation of the heat supply system. An intuitive interface and flexible configuration will help you quickly deal with the nuances of data entry. Small problems may arise during the initial setup of the complex. It will be necessary to enter all the parameters of the system, from the material for the manufacture of pipes and ending with the location of the heating elements.

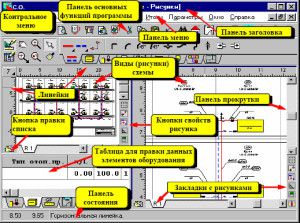

HERZ C.O.

It is characterized by flexibility of settings, the ability to make a simplified hydraulic calculation of heating both for a new heat supply system and for modernizing an old one. Differs from analogs in a convenient graphical interface.

Instal-Therm HCR

The software package is designed for professional hydraulic resistance of the heat supply system. The free version has many limitations. The area of application is the design of heating in large public and industrial buildings.

In practice, hydraulic calculation is not always performed for autonomous heat supply of private houses and apartments. However, this can lead to a deterioration in the operation of the heating system and the rapid failure of its elements - radiators, pipes and a boiler. To avoid this, you need to timely calculate the parameters of the system and compare them with the actual ones for further optimization of the heating operation.

An example of a hydraulic calculation for a heating system: