To organize the heating system, it is necessary to take into account all the nuances - the characteristics of the boiler, the properties of the building, the climatic features of the region and the parameters of the pipeline. Designing the latter is key. The work of the whole complex will whistle on how correctly the pipelines of heating systems were designed: calculation, installation, requirements and diameter of pipes.

Purpose of pipelines and their characteristics

Before starting the calculations and choosing materials, it is necessary to find out the operational features of the heating mains. Their main task is to deliver the coolant from the heating boiler (distribution unit) to radiators and batteries.

At first glance, the installation of a transport highway is not difficult. It is enough to take into account the specifics of the material of manufacture, install expansion joints for heating pipelines in the right places, and ensure tightness. But in fact, after such an unprofessional approach, problems may arise during work. To avoid them even at the design stage, you need to know in advance the basic requirements for the organization of pipelines:

- Nominal pressure and temperature mode of heating... Pipes must withstand the maximum value of these parameters without deformation and changes in their performance;

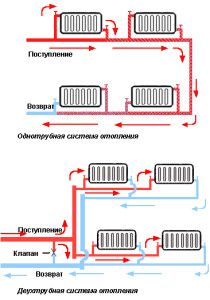

- Take into account the features of the selected scheme - one-pipe or two-pipe. To carry out repair work in certain areas, jumpers are required in the heating pipelines. In particular - when tying radiators;

- External factors - exposure to direct sunlight, the possible influence of negative temperatures and the quality of the coolant. To maintain the initial throughput capacity, heating pipelines are periodically flushed;

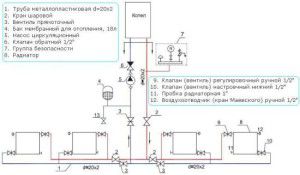

- Observe the installation rules - the angle of inclination, the distance between the heating pipelines and provide for the presence of shut-off valves. The presence of a safety group to compensate for excessive pressure and thermal effects from the coolant.

Where should you start designing heating mains in an autonomous system? First, a diagram is drawn up - one-pipe, two-pipe, collector. Then it is necessary to perform a complete calculation of its characteristics. First of all, select the thermal mode of operation, hydraulic resistance and optimal pressure. Based on the data obtained, pipes are selected.

For systems with natural circulation, large diameter pipes should be installed - from 24 mm and above. In this way, the friction of the coolant against the inner surface of the line can be compensated.

Pipeline material

In order to correctly calculate the diameters of heating pipelines, you should know the features of the material of their manufacture. Currently, polypropylene pipes are most often used for installation, which are characterized by a relatively large thermal expansion.

The determining factor of the choice is the obtained parameters of the system. They must correspond to the performance of the pipes - pressure, temperature conditions, etc.Consider the most common materials for the manufacture of pipelines based on their characteristics.

Reinforced-plastic heating pipelines

Until recently, they were popular for piping. Their advantages are affordable cost, easy installation without special requirements for tools.

However, over time, problems have been noticed inherent in these particular types of pipelines:

- High requirements for the quality of fitin connections - these elements most often failed;

- Sensitive to pressure drop and water hammer. If the installation of heating pipelines was carried out without observing the rules, the likelihood of a rupture increases.

Therefore, most often a different type of pipe is used for installation in the heating system.

Polypropylene for pipeline

It differs from the metal-plastic material of manufacture and the method of connection. For this, heating pipelines are welded using a special soldering device.

Transport lines made of these pipes have better performance characteristics and are devoid of the disadvantages of metal-plastic ones. For the consumer, the total cost of pipelines is also important - polypropylene and connecting components are considered the most affordable option of all on the market.

The features of polymer pipes include:

- Various degrees of expansion of plastic and reinforcing shell (aluminum or fiberglass). It is leveled by expansion joints for heating pipelines;

- Mandatory observance of welding modes, depending on the type of pipe and its diameter;

- Possibility of bends to minimize joints. For products with a cross section from 8 to 32 mm, it is equal to 8 diameters.

For reinforced polypropylene pipes that are used in heating, it is necessary to clean the end of the reinforcing layer before the soldering process. Compliance with this rule is mandatory.

Before flushing polymer heating pipelines, you need to find out the possible effect of the composition of the liquid on the material for making the lines.

Steel heating pipes

Nowadays, you can rarely find steel mains in heating. This is due to the laboriousness of their installation and corrosive processes when exposed to water. Welding heating pipelines will require a special apparatus, as well as certain skills in its operation.

It is important when calculating pipelines of water heating systems to take into account the wall thickness, which is much larger than that of polymer analogs. As an alternative to welding, a threaded connection can be used. But it is less reliable than welded.

The specifics of installing steel pipes are as follows:

- They perfectly withstand high pressure up to 16 atm. In this case, the destruction pressure can reach 50 atm;

- Lime deposits periodically accumulate on the inner surface. Therefore, it is necessary to regularly flush heating pipelines;

- In the presence of an electric boiler, the entire line must be grounded;

- To protect against rusting, it is necessary to paint the pipes.

Steel lines have proven themselves best in centralized heating systems. They withstand critical water shocks, and if maintenance rules are followed, a low rate of formation of a corrosive layer is observed.

Some polymer pipes are damaged by sunlight. For them, concealed installation is recommended.

Calculation of the diameter of the pipeline

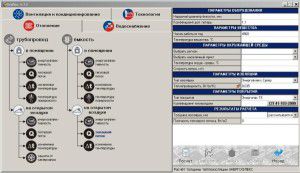

For an accurate calculation of pipelines for water heating systems, it is recommended to use special software systems. When entering the main parameters, they will give the most accurate result.Normal operating modes will be taken into account, as well as the critical pressure and temperature at which the integrity of the line is preserved.

You can do an approximate calculation yourself. To do this, just use the formula:

D = √354 * (0.86 * Q * Δt) / V

Where D - pipe diameter in cm,Q - the value of the heat load on the section in the system, kW,Δt - temperature difference in the direct and return pipes, ° С,V - speed of movement of the coolant, m / s.

To determine the heat load, you must apply the formula.

Q = (V * Δt * K) / 860

Where V - room volume, m³,Δt - the difference in temperature in the house and outside, ° С,TO - coefficient of heat loss at home. For a building with good thermal insulation, it is 0.6-09. For an intermediate level from 1 to 1.9. With insufficient thermal insulation, it varies from 2 to 3.

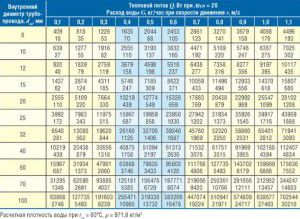

The speed of the coolant directly depends on the heat load. It is fashionable to take these values from the table.

In practice, for the installation of heating pipelines in a private house, it is enough to choose highways with a diameter of 20 to 24 mm. It should be remembered that the cross-section of the jumpers in the heating pipelines should be 1 size less. This is necessary to create the required coolant flow rate in this section of the line.

To reduce friction losses, the number of rotary nodes in the circuit should be minimized.

Heating pipeline installation

For the correct installation of pipelines in the heating system, you should first read the recommendations from the manufacturer. This is important, since the rules largely depend on the material of manufacture and the influence of external factors on the line.

The next step will be familiarization with the regulatory documentation - SNiP 3.05.01-85. It describes the installation standards - the distance between heating pipelines, depending on the presence of a heat-insulating layer, as well as recommendations for the number of fasteners.

| Pipe nominal diameter, mm | The greatest distance, m, between pipe fittings | |

| Non-isolated | Isolated | |

| 15 | 2,5 | 1,5 |

| 20 | 3 | 2 |

| 25 | 3,5 | 2 |

| 32 | 4 | 2,5 |

| 40 | 4,5 | 3 |

| 50 | 5 | 3 |

| 70,80 | 6 | 4 |

| 100 | 6 | 4,5 |

| 125 | 7 | 5 |

| 150 | 8 | 6 |

In addition, the requirements for heating pipelines must be observed during installation:

- For gravity systems, adhere to the correct pipe slope. It should be 0.05 cm per meter. For the supply - the slope from the boiler, for the return - towards the boiler;

- In plastic lines on long sections, it is necessary to install expansion loops for heating pipelines;

- The optimal distance between pipelines in heating is 200 mm - according to SNiP;

- It can be changed upwards if there is thermal insulation of heating pipelines

If there are threaded connections, FUM tape or tow is used. It is preferable to use the latter, since it does not undergo changes when exposed to high temperatures. During the welding of pipelines to the heating system, the distance from the electrical wiring and from the sewer pipes is taken into account. It must be at least 500 mm, which is one of the main requirements for heating pipelines. For correct connection to the radiator, a jumper must be installed in the heating pipe. This is especially true for single-pipe systems.

If polymer heating pipelines are being installed, it is recommended to choose components from one manufacturer. This will resolve the issue of not joining or the quality of the connecting nodes.

It is best to install the installation in the summer. This will give you time to correct any problems that may have arisen during the test run.

Optimization of heating pipelines with insulation

The period of maintenance-free operation is influenced not only by the correctly calculated t of diameters of heating pipelines, but also by the adaptation of the line to the conditions of its operation. Most often, thermal insulation of heating pipelines is performed.

This precaution is necessary to protect the pipes from external influences.They can also be expressed in the following:

- Negative ambient temperature... During crystallization, the water in the line will begin to expand, destroying it. Correctly selected insulation thickness of heating pipelines will protect against this. It is best to use thermal heating cables with it;

- Condensation... The temperature difference between the heating and the environment can lead to increased humidity on the pipes. This negatively affects their condition - especially for metal surfaces. To eliminate this, you can choose a small thickness of insulation of heating pipelines - up to 8 mm.

Taking into account these requirements for heating pipelines, it can be decided that it will be problematic to perform work on the calculation of the choice of material and their installation on their own. It is important to draw up a primary scheme, which must be entrusted to professionals. Installation issues can be solved independently, studying the specifics and "stuffing your hand" in small sections of the pipeline.

How to choose pipes for heating? This issue can be solved by reading the video: