The main task of the sauna stoves is to create a comfortable microclimate in the steam room. When operating in the mode of maximum heat transfer, the walls of the device can heat up to 400 ° C, which negatively affects fire safety and increases the likelihood of thermal burns to the hands and trunk. To prevent these troubles, many bath attendants use a protective screen for the oven in the bath.

When do you need a protective screen

In addition to protecting against burns, the use of heat-resistant structures allows you to block the effects of dangerous infrared rays that are emitted as a result of overheating of the metal walls of the heating device. At the same time, a protective screen for a sauna stove makes it possible to solve a number of other problems:

- control of the supply of convection flows of hot air, contributing to uniform heating of the steam room;

- an increase in the time of heat transfer after the completion of procedures, which helps to dry the steam room faster;

- reducing the risk of fire by preventing walls from heating up to critical temperatures.

Another task of protective screens is to perform a decorative function. Not all heating systems have a pleasant aesthetic appearance against the background of the steam room interior. A special heat-resistant partition is able to give the bath a neat and stylish look.

What materials is it made of

Protective screens are installed in saunas that have metal stoves. In the presence of brick structures, these devices are not needed. It is enough to make sure that there is an air gap between the stove and the wall.

During the manufacture of protective partitions, exclusively heat-resistant materials must be used. These include wood, brick, stainless steel.

Wood

This material is used during the manufacture of decorative fences, which will not allow vacationers to come too close and get burned. Wooden partitions should be located at least half a meter from the heater. If darkening appears on the wood, they need to be pushed even further.

Brick

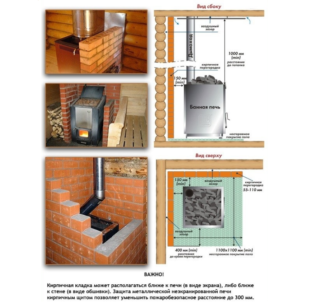

Such partitions should be 20-30 cm higher than the heating system. In the lower part of the structure, gaps should be left to ensure air exchange between the screen and the heater. If necessary, they can be covered with fire doors.

When laying the protective screen, it is recommended to use fireclay bricks. The mortar is made on the basis of clay or cement. The thickness of the masonry can be 6-12 cm. The distance from the partition to the stove must be at least 5 cm. The same distance must be observed between the walls of the bath and the screen.

Stainless steel

The protective structure for the oven in the bath can be made of stainless steel. This is the best option among all types of screens for sauna stoves, since it completely reflects heat into the steam room. Steel partitions are capable of overheating greatly, therefore they are supplemented with a backfill of crushed stone, expanded clay or broken brick.

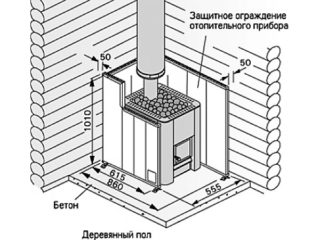

Metal railings for the stove in the steam room are installed in the form of a box or fixed in the corner between the stove and the wall. The distance between the screen and the oven must be at least 12 cm.

How to make a screen for a stove in a bath

The technology for creating and installing the fence depends on the material used. Brick masonry is half or quarter brick wide. In the second case, the load on the foundation will be less, but at the same time the heat capacity and strength of the structure will decrease. When choosing the type of structure, several important details must be taken into account:

- bearing capacity of the floor covering;

- the maximum heating temperature of the furnace;

- the desired rate of warming up the room;

- openness or closedness of the top of the structure.

Solid facing brick is best suited for masonry. Due to its high heat capacity, the room dries out faster after use. Masonry mortar can be purchased at a hardware store or prepared yourself. It is made on the basis of sand and oily clay. You can add 10% cement to it, which will increase the strength of the future structure.

During the independent manufacture of a protective screen for furnace equipment in a bath or sauna, it is necessary to prepare an appropriate set of tools:

- welding machine;

- grinder with cutting disc;

- respirator;

- gloves;

- plumb line;

- building level;

- a hammer;

- Master OK.

The first stage of construction is the preparation of the foundation. If the floorboards in the bath are unable to cope with the weight of the stove and the protective structure, the floor is disassembled under them and a foundation pit is dug to create a solid foundation. When installing additional reinforcements on the foundation, you need to lay a sheet of thermal insulation or minerite. Steel sheets and ceramic tiles can also be used as a base.

After that, you need to choose the material that will become the basis for the future protective screen for the stove in the bath. The best option is stainless steel. The body of the structure is cut and welded from solid sheets of metal. After that, a smaller steel post is welded, which is installed inside to create a heater.

Next, you need to weld an oblong chimney box and weld an additional container for heating water. In this case, the tank together with the heater must fit inside the body. Then a hole is cut out in the front wall of the body, which will allow access to the combustion door, after which the legs are riveted to the bottom.

In the case of using bricks, the masonry is made 5-10 mm from the walls of the heating device so that a channel is formed that will be used to remove hot air. The lower part of the structure must be left with small gaps. In this case, it is necessary to carefully control the evenness of the screen using plumb lines and a building level. The last stage in the installation of the structure is the installation of a canopy or mesh.

The gaps at the bottom of the protective screen are necessary to create air exchange, which will make it possible to increase the efficiency of the heating system. However, they will not reduce the heat capacity of the brick structure.

The holes are often equipped with special doors. When closed, they contribute to the accumulation of heat in the masonry of the protective screen, and when open, they quickly heat up the room.

Common mistakes

During the independent creation and installation of a structure at home, novice craftsmen often make mistakes. Among them, the most common are:

- the lack of sufficient distance between the structure and the walls of the steam room negatively affects the degree of strength of the masonry and fire safety;

- lack of distance between the walls of the furnace and the brick, which contributes to the disruption of air exchange, overheating of the protective screen and cracking of the masonry;

- Poorly mixed masonry mortar leads to crumbling of masonry, cracks and unnecessary gaps.

The technology for creating and installing a protective screen is quite simple.For this reason, even beginners in the construction business can handle it.

A protective fence has a beneficial effect on the efficiency of the heating device located in the middle of the steam room or in the corner of the room. Self-assembly of this type of structure does not require a lot of time and money, and also improves the functionality of the bath and its appearance.