A water gun in a heating system or a flow divider is a special device used for the coordinated operation of its constituent devices and circuits. It is a kind of collector that regulates the pressure of the liquid in each of the water channels. The device got its name due to its functional similarity with a railway switch.

Advantages and disadvantages

The advantages of hydraulic distributors for heating systems include:

- obtaining the optimal ratio of coolant flows in the direct and return pipelines;

- the possibility of installing a low-power circulation pump - reducing the cost of equipment and electrical energy;

- reduction of hydraulic loads in the elements of the heating system;

- extension of service life;

- the ability to remove air from the channels.

There were no obvious deficiencies in the hydraulic separator. But there are some limitations in practical application. The disadvantages of these devices include:

- inadmissibility of work as part of equipment for solid fuel boilers;

- the impact on the functionality of the arrow of the declared power of the boiler unit - with its increase, the reliability of its operation decreases.

In this case, the time of trouble-free operation of the product is also reduced.

Separator device

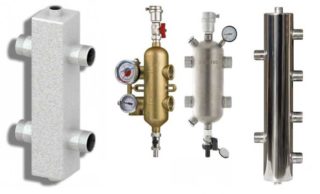

Externally, the separator looks like a piece of pipe with a rectangular (less often - circular) section and two plugs at its opposite ends. This design is connected to the boiler with small pipes and has several more taps in the side. On sale there are products of various shapes and sizes with a simple device. But there are universal models that, according to their purpose, perform two functions at once: a collector and a separator of streams.

The "classic" hydraulic arrow for heating is made in the form of a steel cylinder and has several branch pipes, the size of which is taken into account by the internal section. It is usually mounted vertically, but can be installed horizontally if required. The vertical position is more commonly used because it is easier to remove impurities and vent gases in this position.

In most cases, the arrow is a welded structure based on steel pipes, but the option of making it from copper or polypropylene blanks is not excluded.

Additional features

Features of the functioning of the heating circuit with a hydraulic arrow provide the user with the following additional opportunities:

- When the liquid flow enters the channels of the separator, its speed decreases slightly. This contributes to the deposition of harmful impurities on the bottom, which are always present in the coolant.

- For periodic removal of accumulated sediment in the lower part of the body there is a separate valve valve.

- Reducing the current velocity allows the air bubbles present in the water to be removed from the water. They are removed through an automatic valve.

In the latter case, the hydraulic arrow is used as a separator.

In networks with cast iron boilers, the flow distributor performs the function of additional protection.If there is a hydraulic separator, cold water will not enter the heat exchanger, which can cause damage to the heating elements.

Principle of operation

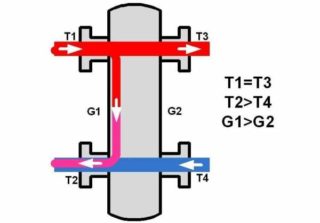

Heating networks are not able to function smoothly, since the circuits are designed for individual performance and a specific indicator for the pressure of the carrier. The principle of operation of the hydraulic arrow is based on the design features, due to which the resistance to the flow of water at the body of the device is minimal. This property allows not to reduce the speed of the carrier, significantly reducing heat losses in the entire network.

In fact, the distributor is a kind of buffer separating the heating equipment (boiler) and the consumer part of the collector. As a result of its application, each individual pump operates autonomously, without disturbing the balancing of the channels.

The low loss header for heating is designed to separate individual flows from the total circuit and coordinate their joint operation.

Separator calculation methods

Before installing the hydraulic arrow, the calculation of individual structural elements is required. When conducting it, the following factors should be taken into account:

- the consumption of the heat carrier in the operating system;

- thermal power developed in each of the circuits.

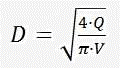

When carrying out calculations, the heat capacity of the working fluid and the difference in temperature of the water carrier in the return and supply channels are also taken into account. The required result is calculated using the following formula:

where D is the required diameter of the product, Q is the average value of the water flow rate (m3 / s), π is the classical constant, and V is the liquid flow rate in the vertical direction (at a rate of 0.1 meters per second).

When self-assembling the arrows and calculating the optimal parameters, they act according to the scheme obtained empirically:

- To find the inner diameter, the sum of all the capacities of the working boiler in kilowatts is taken and divided by the difference in temperature indicators in the direct supply and in the return.

- You will need to extract the square root from the result, and then multiply the total by the number 49.

- To find the size of the gap between the nozzles, multiply the inner diameter by two.

To determine the height of the valve body, the same diameter is multiplied by six.

Combined hydraulic arrow

To connect heating circuits on objects with an area of more than 150 m², instead of the usual separator, which turns out to be cumbersome, special combs are used. They represent a sequential design that combines the capabilities of a hydraulic arrow and a manifold for heating, which are connected with steel bridges for this. The number of double nozzles is selected equal to the number of circuits (they will be required in a couple of pieces). The advantages of this combination include:

- The repair and operation of the entire heating system is simplified. The small-sized structure will not take up too much space in the room.

- The shut-off as well as the regulating part of the valve set can be placed in one place.

- Due to the increased diameter of the collector channel, the heat carrier is evenly distributed along the contours.

To arrange the piping with this approach, special mounting outlets are used, some of which are intended for the radiator circuit, and the other for connecting floor heating.

The features of the combined design include the presence of a special heat exchanger, as well as the installation of a separate balancing valve between the direct and return headers.

Self-manufacturing procedure

To assemble an arrow for heating with your own hands, you first need to carry out theoretical calculations, after which drawings and working diagrams are prepared.It is best to entrust this part of the preparatory activities to a heating engineer who has the necessary theoretical training. A person who decides to make an arrow with his own hands needs to have the skills of welding.

The assembly of any modification of the hydraulic arrow is based on the "3-diameter" rule. The working size of the branch pipes is chosen three times less than the diameter of the main cylinder of the distributor. They are located diametrically opposite, and their height location is tied to the main caliber. A variant is possible in which the taps are made by the so-called "ladder", which makes it possible to increase the efficiency of removing gases and removing insoluble suspensions. In addition, the choice of such a design during self-assembly contributes to the normal mixing of flows.

The ratio of their locations is best chosen so that the speed of movement of the vertical stream reaches 0.2 meters per second. According to the current regulations, it is unacceptable to exceed this limit, since then the water flows do not have time to mix. And this is fraught with the appearance of a temperature gradient and deterioration of the flow distribution conditions.

If you intend to make a multi-circuit heating system with different temperatures of the coolant, you will have to assemble a combined arrow (together with a manifold).

In this case, it is preferable to choose a horizontal scheme, which, unlike the vertical analogue, is not so common among amateurs and professionals. But in this situation, the issues of efficiency of operation of the heating system come to the fore, and not the convenience of its maintenance, cleaning and repair.