Penoplex insulation is a tile material for an insulating layer. This is a type of foam, but significantly superior in most parameters, primarily in strength and density. In order to qualitatively insulate the walls, roof or foundation with penoplex, you need to know what the material is used for and how to properly mount it.

Insulation characteristics

The material is made on the basis of finely crushed polystyrene. It is mixed with special additives and heated. Due to the release of gas under the influence of high temperatures, the molten mass of polystyrene foams. At the final stage of production, the foam is squeezed out of the extruder, after which it cools down evenly on the conveyor belt, taking the form of a plate.

As a result, extruded polystyrene foam is obtained, called penoplex or penoflex - a heater with a homogeneous structure and a pore size of less than 0.3 mm. The main volume of building material falls on the gas filler, which gives a high degree of thermal protection, as well as low weight with significant dimensions. Insulation sheets are orange and usually have typical dimensions: length - 120 or 240 cm, width 60 cm and thickness from 20 to 100 mm.

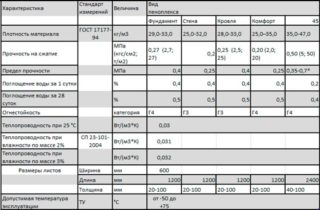

Technical indicators of building materials:

- Heat protection. The boards have good thermal insulation characteristics. Penoplex has a low thermal conductivity coefficient due to its cellular structure, which is 0.03 W / m · ºK.

- Moisture resistance. Due to the fact that expanded polystyrene does not absorb moisture, it can be successfully used for thermal insulation of the roof, basement and foundation. The water absorption rate is 0.5 percent by volume per month.

- Chemical resistance. Does not react with most building materials, excluding solvents.

- Resistance to mechanical damage. Carries heavy loads. For example, at 10% linear deformation, the strength of the material is not less than 0.2 MPa.

- High compressive and fracture strength - 0.27 MPa. This quality makes it possible to use panels not only as insulation, but also as a building material that is not susceptible to the formation of structural cracks.

- Wide temperature range. The average value of operating temperatures at which penoplex does not lose its mechanical properties and physical properties is from minus 50 to plus 75 degrees. If during operation the material heats up more, it can melt, and in frosts below 50 degrees, the insulation will become fragile and brittle.

Mold and fungi do not develop on the penoplex. Only rodents can damage it, which can easily make moves in the material. With proper installation and operation, the insulation will last 35-50 years without losing its thermal insulation qualities.

Advantages and disadvantages of the material

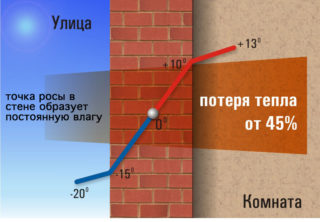

The main advantage is the low thermal conductivity of the foam. It creates a kind of thermos effect. Penoplex panel 20 mm thick in terms of insulation characteristics is equivalent to two layers of mineral wool or a wall lined with one and a half bricks.

Other advantages of the application also follow from the quality indicators:

- light weight;

- moisture resistance;

- resistance to deformation even at temperature extremes;

- ease of installation.

The advantage is the budgetary cost of the insulation.

The disadvantages are low vapor permeability, UV resistance and sound insulation. Good ventilation will help to level the first.

Extruded polystyrene foam penoplex is generally an environmentally friendly insulation. But it burns well, does not belong to fireproof materials. Under the influence of high temperatures, it begins to release compounds that are toxic to humans.

Scope of application

Despite the fact that different types of foam have almost the same thermal conductivity, it is necessary to take into account the thickness and strength characteristics, as well as design features, when selecting building materials for various works.

For thermal insulation with foam plates of different surfaces, a material of a suitable brand should be selected:

- Wall and floor insulation is carried out with C series expanded polystyrene. Its density is approximately 30 kg / m3. The load on the walls is minimal. A feature of the material in this category is that stripes are made on the surface of the sheet with the help of a router, which improve adhesion to the wall or finishing materials. Thermal insulation is allowed both inside and outside the building.

- For thermal protection of a balcony and a loggia, as well as a sauna or a bath, a heater of the Penoplex Comfort series is more suitable. Plates with a density of 25–35 kg / m3 have an L-shaped edge, which, when installed, ensures that there are no through seams.

- The foundation base and the plinth are faced with F-series foam, the density of which is 29–33 kg / m3. It is also used for thermal insulation of septic tanks. This material has increased strength and moisture absorption coefficient is almost zero. For buried foundations, the specialized "Penoplex GEO" is also used.

- Thermal insulation of the roof with foam is carried out using sheets of category "K" with a density of 28-33 kg / m3. The plates have a U-shaped edge, which increases the reliability of the connection. Lightweight, tough, moisture resistant material perfectly protects flat and pitched roofs. If there is a recreation area or a pedestrian zone on the roof, Penoplex 45 with a density of 45–47 kg / m3 is used. It is also used as a heater for road surfaces, in particular for runways, to prevent heaving of the ground at negative temperatures and destruction of the upper layer of the canvas.

For any type of work where insulation is required, you can use Penoplex 50. This is a dense material for universal use, it can protect both the attic space and the foundation base.

Installation methods

Installation of foam sheets is carried out by three methods: on glue, on polyurethane foam and using fasteners. Preparation of walls for insulation is carried out as follows: they are cleaned of dirt, dust, old finishing, paint and varnish coatings are removed. After that, the walls are leveled with plaster and an antifungal composition is applied.

It is desirable to cut sheets with a jigsaw. If you want to cut a curly slab, a heated tungsten string or a thermal cutter is often used.

The panels are glued using special adhesives on a dry wall surface. The glue is applied to the surface of the heat-insulating sheet in a crosswise manner in two lines or in a continuous layer. The panels are glued in rows, from bottom to top, with an offset of the joints.

Mechanical fastening is performed by means of self-tapping screws, at the rate of 4 hardware per square meter. Along windows, doorways and at the corners of the house, the number of fasteners is increased to eight per square.

An alternative option is thermal dowels with wide caps, which are installed in the seam between the panels, while simultaneously fixing several plates.

From above, the insulation is covered with a plaster-adhesive mixture. To increase the adhesion of the plaster to the sheets, you can create a roughness on the surface of the insulation using a card brush.The first layer is applied with a reinforcing polymer mesh. Then the second layer of plaster, after setting which the walls are covered with paint. Instead of plastering, you can decorate the walls with siding, wood, and also install hinged systems for which the frame base is pre-mounted.

If it is impossible to carry out thermal insulation from the outside, you can insulate the walls from the inside. The order of work is similar, but with one difference: the penoplex is closed with foil-clad plastic wrap as a vapor barrier, then gypsum plasterboard sheets are mounted, after which you can start decorative finishing. The frame for installing drywall is fixed by means of dowel-nails to the wall through the panel.

A similar method is used for thermal insulation of balconies and loggias. Tile seams are closed with tape. After equipping the vapor barrier with foil-clad PE film, the joints are also glued with tape - a kind of thermos is created.

Errors when installing insulation

In order for the thermal efficiency of the house to be at its best, you need to avoid the following mistakes:

- Using lighter sheets. This reduces the thermal insulation performance by 2–3 times, which can be seen already in the first 7–10 years of operation.

- The use of incompatible materials. If during the construction, substances are used that are dangerous to the structure of the foam, for example, paint and varnish oil coatings or liquids containing solvents, this will cause the panels to collapse.

- Incorrect installation. If you leave a gap between the wall and the insulation coating, the dew point will shift into it. The wall will inevitably absorb condensation, which will greatly reduce the thermal protection.

When selecting slabs, it is imperative to take into account the grade of the material, which will allow you to purchase an option that is suitable for strength and not get out of the estimate.

Analogous materials

Sheet foam has analogues, for example, teploplex. Both materials are similar in quality and outperform foam, with the exception of vapor permeability.

Building material "Technoplex" is more frost-resistant, it will withstand minus 70 degrees without destruction of the structure, in other respects it is similar to penoplex, but it costs more.

Polyplex 2000 is another insulation made of extruded polystyrene foam. It has better soundproofing properties than simple penoplex, but the price is also higher. For work in the loggia or on the balcony, you can choose the foil option - penotex.

The use of foam as an insulating material allows you to significantly save on heating costs in the cold season and reduce heat loss inside the house. If you choose a suitable brand, follow all the instructions for installation and operation, the insulation layer will retain its positive qualities for many years.