The electric boiler is a profitable alternative to solid fuel or gas appliances. It has increased efficiency, does not make noise during operation, does not require a separate room and obtaining a special permit for installation. Electric boilers for heating a private house for 380 V belong to the category of powerful three-phase appliances and are divided into several types. Before buying and installing such a boiler, it is useful to study its pros and cons, the rules of operation and installation, as well as the available connection options.

Types of electric boilers

Electric boilers for heating a private house for 380 volts can be heating elements, electrode or induction, depending on the type of energy transfer to the heat carrier. Manufacturers offer floor and wall options suitable for large and standard houses and cottages. They have different degrees of protection and increased efficiency.

Electrical units can be three-phase or single-phase, the first option is usually chosen for houses with an area of more than 100 meters. The power of three-phase boilers starts from 10 kW, the list of their advantages includes a stable voltage and circuit protection. However, they are limited in terms of installation, since the installation of a step-down station is required. To find out which of the models to choose, it is better to contact a specialist.

Heating elements

Such units are considered the most popular and work according to the same principle. The tubular element heats the water circulating inside the system, which ensures uniform and fast heating. Inside such a boiler there can be from 1 to 6 heating elements, their number directly depends on the power of the device. The heating element three-phase electric boiler is equipped with a special automation system, due to which the temperature of the heat carrier is monitored and regulated.

The device has a simple and reliable design, easy to install and does not cause problems during use. Boilers on heating elements are quite cheap, almost any liquid is suitable for them as a heat carrier. In addition to the main advantages, modern heating elements are distinguished by their laconic and modern design, which allows them to fit into any interior. It is necessary to use high-quality heat transfer fluids to prevent the appearance of scale.

To reduce scale formation, anode rods are installed to collect excess salts. They can be changed as they wear out, like the heating elements themselves.

Induction

Electromagnetic induction boilers are often used for residential applications. Inside the cylindrical body of such a device there is a metal core with a coil wound around it. When voltage is applied to the coil, a vortex flow is formed, due to which the pipe with the circulating heat carrier heats the water. To avoid overheating, the water must be circulated constantly.

The efficiency of such devices reaches a maximum value of 98%, which makes induction boilers the most efficient. In addition, a 3 kW electric boiler for 3 phases is not subject to scale formation inside and is considered the safest, since there are no heating elements in it. The induction units can be installed in the shortest possible time due to their low weight and compact dimensions.

An induction heating boiler does not need a circulation pump if it is used in a home heating system. This part is required for large systems in multi-storey buildings.

Electrode

Electrode-type boilers operate on specially prepared water, in which salts are dissolved to increase the density to the desired level. A three-phase electric boiler consists of a pipe into which a pair of electrodes are inserted. Due to the potential difference and polarity change, the ions inside begin to move chaotically, as a result of which the heat carrier heats up faster.

Thanks to the accelerated heating, powerful convection flows heat up a large volume without the need for a circulation pump. Of the advantages of 380 kW electrode devices, compact dimensions, an accelerated achievement of rated power, a simple design and a low accident rate, even if water begins to flow out of the heating system, are noted.

For electrode assemblies, earthing is provided. The boiler and all elements of the heating system in the house are connected to the grounding circuit.

Advantages and disadvantages of three-phase boilers

An electric boiler for heating a house for 380 V has more advantages than disadvantages. The units are reliable, do not cause difficulties during installation, are presented in a wide price range and functionality. They are cheaper than gas ones and at the same time are equipped with a simple and convenient automation system, including a list of modes, a GSM controller, the ability to maintain the desired temperature. Also, the list of pluses includes:

- compact size and aesthetic design;

- no problems during use;

- silent work;

- increased efficiency.

The main drawback is the high cost of electricity and associated costs. Electric boilers are completely power-dependent. Only high-quality coolants with a specially selected composition are suitable for them.

Rules for the installation and operation of 380 V electric boilers

It is necessary to connect any 380 V electric boiler in compliance with all the requirements for safe installation. It is important to correctly calculate the cross-section for the power cable, on which the safety of the entire system as a whole depends. Since 380 kilowatt devices are the most powerful, you need to select the most durable cable. The cross-section is calculated according to the formula, taking into account which no more than 8 A of current falls on 1 mm2 of the cable.

During the operation of the boiler, they monitor the health of the electrical wiring and prevent leaks of the heat carrier. You also need to pay attention to the performance of the grounding conductor. If there is any damage, de-energize the unit as soon as possible and completely restore the grounding. Modern devices with a power of 380 W have proven themselves well during long-term operation. To avoid problems, you need to follow the rules:

- do not touch the grounding elements;

- entrust repairs only to qualified specialists;

- check the power supply before turning on;

- periodically flush the boiler;

- control the temperature;

- avoid mechanical damage to the boiler.

To monitor the heating level and control the system, you can optionally install a special thermal switch. It will block the operation of the boiler in emergency situations and help to avoid possible problems.

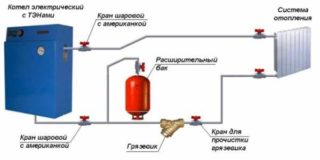

Connection to the heating system

To connect a three-phase boiler, you must adhere to a special scheme. It is better to entrust this process to a specialist who must understand heating devices and know the principles of operation of sensors, pumps and other elements. The diagram for connecting electric boilers to the heating system consists of several standard steps. To avoid possible problems, you need to follow the basic rules:

- To fix the elements of the unit, you need to use plastic pipes or jumpers made of dielectric material.

- The circulation pump is placed on the return pipe.

- A safety group is placed on the pipe for supplying a heated heat carrier.

- When using a small circuit, shut-off valves must be installed after it.

An open expansion vessel should be positioned at the top of the system without the need for locking devices. Closed tanks are placed near the device to the shut-off valves.

380V electric boiler manufacturers

Bosch boilers are considered the most versatile. Models of the popular Tronic series are equipped with safety valves, have a capacity of 7 liters and a maximum heating area, are able to quickly heat water and are presented in a large list of options. Ferroli devices are usually purchased for multi-storey buildings. They are equipped with an integrated circulating water supply system and are energy efficient thanks to the optimal pump performance. In inexpensive models, the efficiency is less than 100%, the pressure of the thermal carrier is 0.4-0.6 bar.

On the electrical diagram, there is no output of the working neutral after the difavtomat.