When designing heating, attention is paid to the availability of energy sources, the cost of equipment and the cost of connecting to power grids, operating costs. In some cases, the owner is forced to be heated by electricity. Which electric boilers are better for a private house should be found out in advance, even before going to the store. Units differ in characteristics and design. Only a comprehensive assessment will help you make the right choice.

Features of electric boilers

When deciding which electric boiler to choose for a particular house, several factors are taken into account.

For gas equipment, technological connection will cost a fixed amount of about 50 thousand rubles. But this is if the highway runs along the street. In other cases, the amount reaches 1 million. Additionally, it is worth considering the cost of the project.

For the installation of an electric heating boiler, no approvals are required, the power grids that have already been introduced into the house are enough. According to the law, the cost of a new connection does not exceed 1000 rubles.

The limitation is imposed only by the allowed power. The issue is resolved with the supplying organization.

Advantages and disadvantages

Electric boilers have positive and negative properties, which must be taken into account.

The advantages include:

- electrical and fire safety in the case of installation of differential circuit breakers or residual current devices;

- low cost;

- high, up to 95%, efficiency;

- the possibility of self-installation;

- noiselessness (not for all types);

- convenience of regulation and control, including the option of remote switching on and setting the temperature in the “smart home” system;

- a wide choice in terms of power, design, functionality.

The disadvantages are associated with the high costs of paying for electricity during round-the-clock operation, inoperability during network outages. During the initial installation, it will be necessary to modernize the electrical network to a state in which it will withstand the maximum power of the equipment.

General principles of construction

The design of all types of electric boilers is made according to the general scheme and consists of structural components of the same purpose.

The device contains:

- heating element;

- heat exchanger;

- control and protection devices;

- body;

- fittings for connecting to utility networks.

The principle of operation is simple: a heating element installed in the heat exchanger, under the influence of an electric current, brings water or antifreeze to a predetermined temperature. The circulation pump creates the movement of the coolant through the pipes and radiators of the heating system. Hot water is cooled in batteries and returned to the boiler.

Then the process is repeated. All types of boilers work according to this principle.

Electric double-circuit boilers for heating and water supply, in addition to the heat carrier, heat water for household needs (sink, shower). The contours are completely separated.

Antifreeze can be used for heating, it does not mix with water for food and hygiene purposes.

Options for selection

The power of the equipment is matched to the size and energy efficiency of the house.A boiler of insufficient power is not able to warm up the structure to a temperature acceptable for life.

The boiler is chosen with a margin of 10 - 15% of the maximum power required for heating. This comes in handy on especially frosty days. At the same time, equipment operating at the limit of its capabilities serves much less.

Boilers designed for 220 V are capable of heating a room for a maximum of 80 m2, subject to high-quality insulation of building structures.

The influence is exerted by the remoteness of the housing from the distribution substation, preferably no further than 2-3 km.

Houses over 80 m2 are heated with three-phase 380 V units. Models on the market are capable of heating a house with a maximum area of 400 m2. If the building is larger, two or more boilers are installed.

An important point is the appearance of the device and the installation method. Boilers are manufactured for installation on the floor and for wall mounting, which must be taken into account when designing heating pipelines. Models with unusual design solutions are more expensive than their counterparts in classic cases. If the boiler room is located in an enclosed space, choose models without frills.

The price of the equipment depends on the quality and brand. It is worth reading user reviews on forums and social networks about the model you like. Often, products from a well-known manufacturer are unreasonably expensive. After analyzing the information received, they select an aggregate that is affordable for finance.

Heat carrier heating method

The type of heating element directly affects the consumer properties of the boiler. Manufacturers use three types of electric heaters:

- tubular;

- electrode;

- varieties of induction.

The efficiency of all structures is in the range of 90 - 95%, but there are operational features.

Heating elements

Tubular electric heaters (heating elements) are used in boilers of low and medium power.

Inside the steel or titanium alloy tube, there is a high resistivity nichrome coil. When an electric current passes through the spiral, it heats up, gives off heat to the tube, which heats the coolant.

Heating elements are inexpensive, standardized for seats or threads on the body.

Replacing a failed heater is easy and quick to carry out on its own.

The disadvantage of the design lies in the large thermal inertia, until the temperature of Taine himself reaches the operating mode, it takes 10-15 minutes, and the process of heating the water is slow. It is more profitable to use boilers with such heaters during round-the-clock operation. At the dacha, you will have to wait a long time for the rooms to warm up.

When buying equipment, they immediately purchase a spare heating element, so that in the event of a breakdown, you do not have to look for a replacement for a long time.

The disadvantage of this type of heater is the formation of scale on the tube walls. Scale does not transmit heat well, the walls do not cool sufficiently and burn out quickly.

Several methods of protection against scale have been patented, The most common and affordable is the installation of heating elements with a protective anode.

The anode is a replaceable part. The principle of operation is based on the fact that the part is gradually destroyed by ions, the scale does not settle on the heating element, but precipitates.

Other methods, using the magnetic field that the heating coil creates, are not yet common in affordable boilers.

An important drawback is the loss of power when the supply voltage drops. This is taken into account in places remote from the transformer substation and in suburban areas with worn out power lines.

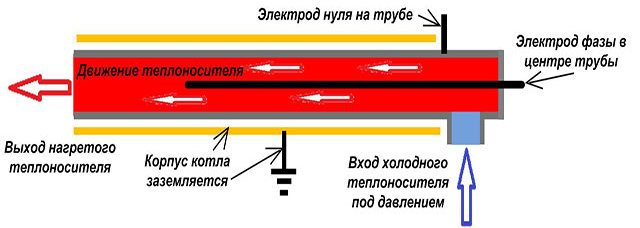

Electrode

Ion exchange or electrode boilers quickly became common in households.

The principle of operation is the flow of an electric current between two electrodes.

Geometrical dimensions depend on the number of supply phases and power consumption.

The advantages include:

- low prices for spare electrodes;

- long service life compared to heating elements;

- in the absence of water, the heater will turn off automatically, since the current will stop flowing between the electrodes;

- immediate start of electrolyte heating after switching on;

- high power.

For efficient operation, only a special electrolyte can be used as a coolant. Adding salt to the water has a temporary effect, but serves as an excuse for the seller and manufacturer to refuse warranty obligations.

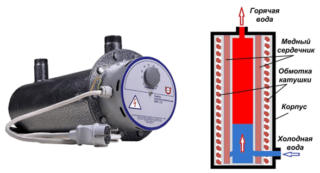

Induction

In everyday life, induction boilers began to be used in the early 2000s.

Heating occurs due to electromagnetic induction. An alternating voltage is applied to a coil, which creates an electromagnetic field. It, in turn, heats up the core.

The heated core heats the coolant.

Heating water to high values is faster than other types. There is no scale in devices, so any liquid, even from the main water supply, can be the coolant.

The disadvantage is the complexity of the design and special equipment for supplying high frequency alternating voltage to the heater. Self-repair is not possible or available only to trained users.

The vortex type is one of the varieties of induction heaters. The work takes place due to high frequency currents.

Induction and vortex heaters generate noise during operation. Install such equipment only in specially designated rooms. The feature applies to inexpensive products.

The disadvantage of induction and vortex models is the high price.

Top manufacturers

There are more than a dozen manufacturers on the electric boiler market. Retail chains give preference to brands whose products are less likely to fail, and the warranty is fulfilled in full.

The table contains factories whose products are popular.

| Brand name | Country | Boiler power range, kW |

| Protherm, SKAT series | Czech Republic | 5–28 |

| Buderus, a division of Robert Bosch GmbH | Germany | 20–60 |

| Kospel | Poland | 4–36 |

| Vaillant | Factory in Slovakia, owner Proterma | 5–28 |

| Bosch | Germany | 4–24 |

| RusNIT | Russia | 3–100 |

| Evan | Russia | 2,5–400 |

| Ferroli | Italy | 6–28 |

| Ariston | Italy | 2,5–24 |

The automation in the products of the presented manufacturers is made with high quality, spare heating elements are relatively inexpensive.

Each of the brands has a network of authorized service centers in Russia, therefore, warranty and post-warranty repairs are not associated with great difficulties.

Buyer's guide

Based on the project of the house, the quality of insulation and the planned version of the heating system, they specify:

- the required power of the boiler, sufficient to heat the house with a margin of 10-15%;

- purpose - heating or heating plus hot water supply (DHW);

- permitted connection power in the household and the type of power supply (1 or 3 phases);

- the condition of the electrical wiring and entrance to the house, if necessary, purchase of differential circuit breakers;

- type of installation - wall or floor;

- the desired type of heater, taking into account power and noise;

- the presence of a built-in control system, the need to purchase any external components.

Do not pay attention to the advertising promises of manufacturers about the increased efficiency of devices - boilers of any type convert up to 95% of the consumed electricity into heat.

Electric boilers are affordable, easy to install and maintain, and can easily withstand the service life declared by the manufacturer. By choosing the right equipment and following the installation and operating instructions, the user is provided with a reliable heating device.