A comfortable environment in a city apartment or a country house is not only attractive design and high-quality furniture, but also warmth. For full heating of living quarters, especially country houses, a warm floor is used. Unfortunately, electric heating is not always possible to install, so people prefer water systems. If there is no centralized heating system, an electric boiler for a warm water floor is additionally installed.

Features of the operation of underfloor heating without radiators

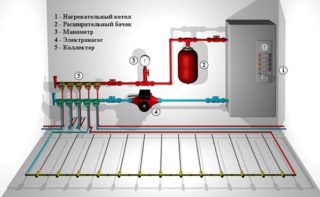

There are several types of floor heating systems - infrared, electric and water. In most cases, homeowners prefer water systems. A coolant is continuously circulating through the main pipes, which is warmed up in a special electric boiler for underfloor heating.

Boilers are often used to heat various premises, for example, residential apartments and houses, offices, garages, etc. This demand and prevalence is due to the complete safety of use in rooms with people and compact size. Modern heating systems are additionally equipped with temperature control sensors, which will allow you to regulate the microclimate in the rooms.

Despite the large number of advantageous features, builders do not recommend limiting themselves to installing a warm floor. Heating radiators are a must. To maintain the optimal temperature in the house, the floors will have to be warmed up to at least +30 degrees. Many floor coverings cannot withstand these conditions. Thanks to radiators, the air in the room heats up faster and more evenly.

Types of boilers for underfloor heating

Boilers for heating the coolant are divided into several varieties. They differ in the peculiarities of functioning, the method of installation and the fuel due to which they work.

Diesel boilers

These modifications work thanks to diesel fuel. Such models are characterized by high performance and efficiency, they are completely autonomous in their work.

The boilers are quite easy to install, they are easy to use, have high efficiency rates, and consume small amounts of fuel.

Solid fuel equipment

The fuel for such modifications is pellets and firewood. The principle of operation has a lot in common with burning wood in a conventional stove. Combustion occurs at high temperatures (more than +250 degrees), there is no air access. The heating medium heats up due to the release of hot smoke during fuel combustion.

Solid fuel types of boilers in residential premises are rarely used, they are most common in industries and in agriculture. Operation at home is complicated by the need to constantly load wood or pellets.

Gas boilers

The equipment runs on gas. Boiler bodies are predominantly made of steel or cast iron, which guarantees a long service life.

Steel models are much lighter in comparison with cast iron ones, they have compact dimensions, they are maintainable.Cast iron models have a longer service life, but the cost is slightly higher. The systems can operate on main gas and on liquefied from cylinders. The devices are economical; for floor heating, you can take low-power models.

Electric boilers

Electric boilers can be used in all spheres of human life. The advantage of such devices is that they make it possible to realize low-temperature heating of the floor covering.

Calculation of boiler power

The boiler capacity is calculated according to a special formula. It is generally accepted that for every 10 sq. M. there must be at least 1 kW of thermal energy. If homeowners plan to install a double-circuit boiler, an additional 30% must be added to the result.

In parallel, it is important to take into account the features of the operation of double-circuit boilers. When DHW is connected, heating of the heat carrier does not stop. At these moments, the wiring is subject to peak load, so the wiring must comply with all the technical parameters prescribed in the regulations.

The results obtained are always rounded up.

Criterias of choice

It can be difficult to choose an electric boiler for a warm one due to the large assortment of equipment in stores. The following points are determined:

- Manufacturer. Italian, Czech, German and Russian manufacturers specialize in the manufacture of electric boilers.

- Power, which is calculated from the heated power.

- Equipment functionality. Not all household electric boilers are designed to connect a warm floor to them.

If you cannot choose the equipment yourself, then it is better to seek advice from specialists.

Top manufacturers

There are a large number of manufacturers of electric boilers, but judging by the technical characteristics and experience of use, it is better to give preference to the following brands:

- Buderus Logamax, E series;

- ATON Electro;

- Kospel EKCO;

- GALAN, series OCHAG, GEYSER and VOLCANO;

- Ferroli LEB and Ferroli ZEWS;

- Barsky Machine-Building Plant Zh7-KEP.

It is recommended to purchase equipment from official representatives or in large chain stores that provide a guarantee and quality certificates.

Connecting an electric boiler for a warm water floor

Installation of an electric boiler, unlike diesel and gas, does not require approval from government organizations. Can be installed independently. Installation should be carried out taking into account all the requirements of the PUE.

You need to connect the equipment with your own cable and to your own machine, it is important to take care of grounding.

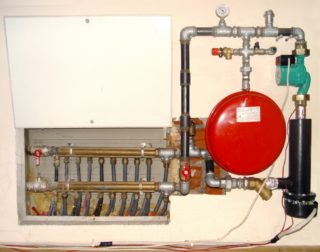

To connect an electric boiler to a water floor, an RCD is not required. It is important to equip the system with a manifold assembly, which will ensure uniform distribution of the hot coolant throughout the system.