The wall-mounted gas boiler Navien is a sample of products manufactured by the Korean company of the same name for many years. Amateurs and specialists know its products as reliable and high-quality units that can serve for many years. This is confirmed by numerous reviews of people who have bought and operated equipment for several decades. However, sometimes troubles occur, expressed in breakdowns of some aggregate units. To learn how to diagnose the detected malfunctions, you will need to carefully familiarize yourself with the technical characteristics of the Navien gas boilers offered by the company.

Manufacturer information

KD NAVIEN is one of the leading manufacturers of heating systems and all types of industrial electrical installations. It was founded in 1978 and since then has enjoyed a well-deserved reputation among consumers. The modern technological base and powerful economic potential of the Korean company make it possible to constantly expand the range of attachments. Much attention is paid to new developments and their introduction into the technological cycle. This approach to the organization of production allows you to quickly respond to all changes in market conditions.

An active policy in the field of innovations has allowed KD NAVIEN АС to hold a leading position for a long time in most segments of the heating equipment market.

The company has achieved particular success in improving the environmental friendliness and waste-free operation of heating installations. Significant achievements have also been noted in the areas associated with universal systems that allow the generation of both heat and electricity.

The advantages of the products of this company include:

- environmental safety of manufactured products;

- automation of production processes, which allows to reduce the final price of the product;

- the presence of built-in protection against sudden voltage drops in the network and the possibility of arranging a double-circuit piping;

- Convenience and ease of control of the unit

Relative disadvantages of these products include dependence on power supply and excessive noise.

Types of wall-mounted boilers

There are three types of wall heating devices of the class in question on the domestic market:

- boiler Navien atmospheric (open) type;

- turbocharged wall models;

- condensing devices.

Each of these positions needs separate consideration.

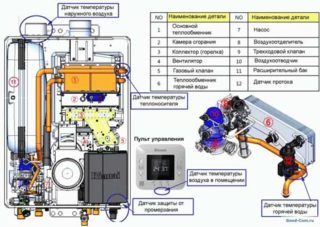

Atmospheric gas boilers

Units of this type have an open combustion chamber. Presented by the Navien Atmo model. It is intended for operation in conditions of uneven gas pressure (its drops can reach 8-17 mbar) and the coolant itself - from 0.6 to 8 bar. The power of the offered units varies from 13 to 24 kW. At an operating temperature of 80 ° C, the heating medium heats hot water up to 60 ° C with an output of 10 liters per minute. To remove combustion products, they are equipped with standard chimneys.

The heating circuit in atmospheric boilers is made of copper, and the heat exchanger body is made of stainless steel.

The markets of Russia and the countries of the former USSR are supplied only with wall-mounted and floor-mounted double-circuit units. A portable remote control is used to control the gas boiler.All samples of Navien Atmo products are protected against freezing of the coolant, their efficiency is about 86%.

Turbocharged units

The group of units of the second type (with an isolated combustion chamber) includes models of the following series:

- Prime, represented by boilers with a capacity of about 13-35 kW;

- Deluxe, the declared power of which ranges from 13 to 40 kW;

- modern Smart TOK models with an indicator of 13-35 kW.

Portions of air are forced into the isolated combustion chamber - they are forced through a special fan installed in the coaxial pipe. Thanks to this, units with a Coaxial design have a higher efficiency, sometimes reaching a record figure of 93%. Gas boilers from the Navien Deluxe series are capable of withstanding significant supply voltage fluctuations, since they are equipped with a built-in stabilizing device. In addition, they provide an option to automatically maintain the temperature of the media at a level not lower than the "cooling point" (6-9 degrees).

Condensing boilers

The third type of Navien gas boilers is represented by samples of equipment from the NCN and NCB series. Due to additional heating of the carrier by the heat of condensate, their efficiency was raised to 99%. The functionality of these units is even higher than that of turbocharged boilers - the controller built into them allows you to set the temperature parameters for a week in advance.

The Navien NCN series of products includes four varieties from 22 to 40 kW, while the NCB has the same number of products with indicators of 24-40 kW. The water in them heats up to 65 ° C, and the coolant circulating through the pipes - up to 90 ° C. These units are capable of withstanding carrier pressures up to 10 bar.

Air supply in equipment of this class is organized by means of a coaxial or conventional chimney.

Operation of gas boilers Navien

The place for the installation and permanent operation of the gas boiler is selected taking into account the following points:

- the unit hung on the wall must be at least 60 cm away from other household appliances;

- the room with the placed device is equipped with an effective ventilation system;

- the power supply socket is located at least 30 cm from the boiler drum.

To connect it at the installation site, you will need to supply a separate power line. Since the power consumed by it (and hence the current in the circuit) reaches a significant value, it is forbidden to turn on the device through a conventional adapter or using extension cords. According to the PUE, the branch for the unit must meet the following requirements:

- supply voltage - 220 Volt 50 Hz;

- the cross-section of cable cores is selected based on the power of the equipment being installed (at least 2.5 cm square);

- the supply line is protected by a separate circuit breaker and an RCD.

In accordance with the current safety standards, the body of the gas boiler must be earthed.

Trial switching on and off

To start the boiler on its own, a number of preparatory operations will be required:

- fill the system with a water carrier;

- remove air residues from it;

- check the pressure inside the working circuit.

If it falls, turn off the boiler immediately and check all interfaces for leaks.

The first two operations are carried out in accordance with the instructions attached to the equipment, which describe in detail all stages of start-up work. When no deviations from normal modes are found, you can proceed to its daily operation.

Possible mistakes

Errors displayed during self-diagnostics of products from a Korean manufacturer are described using the example of the well-known model of boilers Navien ACE 24.

Built-in troubleshooting prevents serious equipment failures at the earliest possible stage of equipment failures.

When a malfunction is detected, the electronic protection disconnects the gas unit from the network, blocking the entire heating process. At the same time, an error code is displayed on the screen or display of the device. Despite the fact that the built-in diagnostic systems were developed for specialists, an ordinary user is quite capable of independently understanding this issue and taking the necessary measures.

Error codes

Typical malfunctions of the Aisa Navien gas boiler are reduced to several groups of malfunctions, which are represented by the following error codes:

- 01E means that the equipment is experiencing overheating detected by the temperature sensor;

- 02E indicates the appearance of leaks in the circuit monitored by the flow sensor (for a decrease in the level of the coolant);

- 03E indicates the absence of a signal confirming the presence of a flame (even if the burner is working);

- 04E - indicates the presence of a flame in its physical absence (a short circuit in the flame sensor circuit is also determined);

- 05E - a typical error that occurs when the medium temperature measurement circuit is malfunctioning in the heating circuit;

- 06E - temperature sensor breakdown code (DT), meaning the presence of a short circuit in its circuit;

- 07E - an error that appears when the diesel fuel line is faulty in the DHW circuit;

- 08E - malfunctions with the same sensor, but arising from a short circuit in its circuit.

An error under the designation 09E indicates a malfunctioning fan, which needs to be carefully inspected and replaced. Error 10E indicates that there is a problem with the extraction of smoke, and 12E indicates that the flame in the burner has gone out.

The next block of ciphers that appear in the event of a malfunction:

- 13E indicates a short circuit in the flow sensor of the heating circuit;

- 14E is a code for the absence or violation of the normal mode of gas supply from the main;

- 16E - an error that occurs due to overheating of equipment nodes;

- 18E - violations related to the operation of the smoke extraction system (sensor overheating, for example).

It can be concluded that the most unreliable node is the control board. But in reality this is not the case, since it breaks down much less often than the sensors it serves.

There are no special instructions on how to eliminate the problems that have arisen in the accompanying documentation. The manufacturer explains this by the fact that representatives of the service company are engaged in the maintenance and repair of gas equipment from Navien. When the user decides to remedy the malfunction on his own, he must understand that he voids the warranty.

Features of choice

The most popular among consumers are the white varieties of Navien boilers with a declared power of up to 16 kW. They are presented on the sales market by the following original models:

- products of the Deluxe Plus 16K brand;

- wall-mounted boilers Deluxe Coaxial 16K White;

- equipment under the brand name ATMO.

All units marked with the Kotel brand name have similar characteristics, and small differences mainly concern only individual units and parts. When buying them, special attention is paid to the warranty provided by the manufacturer and the availability of a quality certificate. The demand for samples of boilers with a declared power of more than 25 kW is not so great, since their cost is significantly higher.

Gas boiler care

To avoid malfunctions in the operation of the boiler, you should master the basic techniques of caring for it. In order not to bring the situation to the need for repair, the user needs to adhere to the following operating rules:

- keep the boiler clean, avoiding the accumulation of large amounts of dust;

- periodically check the voltage in the network;

- control the pressure of the coolant and prevent it from falling below the limit level.

The manufacturer does not recommend servicing the gas heating unit on its own and touching its electrical circuit. It is only allowed to follow the distances specified in the instructions from the walls and other objects - at least 15 cm.

Careful acquaintance with all typical errors and the ability to eliminate their consequences will help ensure reliable protection of the purchased equipment.