Bimetallic radiators are gradually but surely conquering the market. Rifar Monolith batteries stand apart in the assortment. Quality and reliability are the main characteristics of the model.

The essence of bimetallic technology

A feature of bimetallic radiators is the use of two metals in the construction.

The steel from which the inner filling is made is responsible for the strength and durability of the structure. The outer layer is made of aluminum, which is slightly corrosive and gives the finished product an attractive appearance.

The meaning of the technology is as follows:

- Steel heat-conducting channels are welded with internal collectors, which are needed to connect the sections to each other.

- High pressure casting of the outer layer. The inner "frame" is made of steel and is jacketed with aluminum.

- Assembly of finished radiators from several sections.

The advantages of the technology are due to the properties of metals:

- steel gives the structure strength;

- aluminum gives off heat well, is externally attractive;

- bimetallic batteries are lighter than their cast iron counterparts, they can withstand high pressure and water hammer.

The main problem of sectional products is the presence of joints. Mechanical connections are susceptible to leaks, corrosion, and destruction by water hammer. Rifar Monolith 500 batteries do not have these disadvantages.

Features of the Monolith series

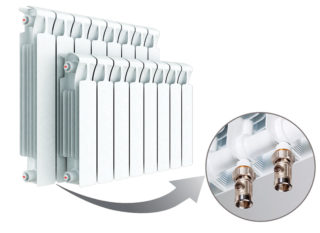

Externally, the batteries of the Russian company Rifar are similar to sectional counterparts. The design feature is hidden in the designation "monolith".

In the versions (Monolit or SUPRemo), the concept of "section" is generally absent. The inner part of the metal is made as a whole, without nipples and gaskets at the joints. Accordingly, the outer shell is also one-piece.

Heating radiators of the Monolit series cannot be disassembled into separate sections, add a section to increase heat transfer, or replace a component. Therefore, the calculation of heat transfer is carried out at the design stage.

To prevent corrosion of the inner surface, the tubes are coated with a layer of silver. The absence of protrusions, minor irregularities makes the advancement of the coolant easier.

The manufacturer does not impose restrictions on the chemical composition of the coolant. The company guarantees the absence of corrosion when used in the system of industrial water or antifreeze.

The patented welding technology makes the structure close in performance to seamless. This increases the tensile strength with increasing pressure.

The thickness of the supply pipes corresponds to the thickness and diameter of the distribution pipes, which facilitates installation.

The cost of one section from the manufacturer is 880 rubles. To obtain the final cost, the number of sections is multiplied by this amount. Rule: the more sections, the cheaper the unit cost of one - the Monolith does not work in models.

Important specifications

Technical parameters of bimetallic radiators Rifar Monolit 500 allow operation in any buildings with heating systems that meet GOST standards.

The manufacturer guarantees the technical characteristics:

- working pressure - 100 atm;

- test pressure - 150 atm;

- short-term breaking pressure and load during tests in accordance with GOST 31311-2005 - 250 Atm;

- the maximum temperature of the coolant is 135 ° C;

- connecting size 3/4 ″;

- delivery with 1/2 ″ branch pipes is available on special order;

- center distance of connecting pipes - 500 mm;

- dimensions, height, width, depth, mm - 577x80x100;

- heat transfer of one section - 196 W;

- internal volume of the section - 0.2 l;

- section weight - 2 kg;

- The number of sections in the finished product is from 4 to 14.

The manufacturer guarantees the preservation of the listed parameters within the normal range for 25 years of operation.

Battery use Monolith

The plant recommends using batteries of the specified series for heating any residential, industrial and auxiliary buildings.

The increased strength allows for installation in high-rise buildings.

For production, grades of steel and aluminum are used that allow the installation of the Monolith battery in preschool institutions and schools, hospitals and catering establishments.

The anti-corrosion coating does not deteriorate under conditions of short-term exposure to high humidity, so monolithic batteries can be used to heat basements and garages.

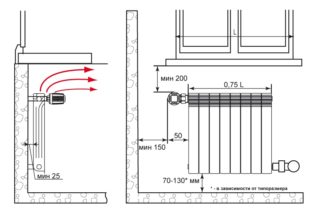

Installation requirements

All the advantages of Rifar Monolith batteries are manifested only with proper installation. Mandatory recommendations are indicated in the product passport.

Before installation, a heating project is drawn up in accordance with the guidelines GOST 31311-2005, SNiP 41-01-2003, SNiP 3.05.01-85 and SO 153-34.20.501-2003. This requirement is mandatory if the maintenance service is planned to be entrusted to a specialized organization.

In private houses, there is no such strict requirement, but it is recommended to draw up a project to equip a reliable system - this will help to restore operability in case of accidents.

Installation work is carried out in accordance with the methodology of the Ministry of Construction, the organization responsible for further operation oversees the construction progress.

During installation, the radiator is naturally heated (cooled) to the temperature of the room where the installation is carried out. It is forbidden to use heaters to speed up the process. The requirement is due to the fact that when the temperature changes, metal deformations occur and the joints with the supply pipes can lose their tightness.

Mandatory installation of taps with the ability to block the inlet and outlet of the radiator.

Do not remove the protective film before use, so as not to damage the coating.

An air removal valve is installed on the side opposite to the inlet pipe.

When tightening threaded connections to avoid breakage, the force should not exceed 55 N / m.

Transportation

Delivery of radiators can be carried out by any means of transport. Product stacks are securely secured against movement.

Store products in closed rooms or under a canopy. Exposure to the packaging and body of aggressive chemicals is not allowed.

As an exception, storage is allowed for up to 10 days in open areas sheltered from precipitation.

The distance from the floor to the lower edge of the device is chosen from 70 to 120 mm, and to the window sill at least 80 mm - this is the optimal solution for heat transfer. 30 - 50 mm recede from the wall.

Strictly horizontal position will protect against frequent airing of the internal cavities of the product.

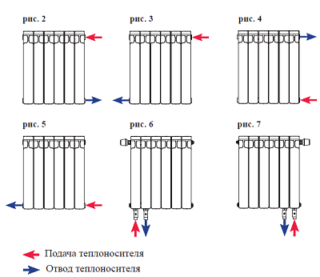

Acceptable wiring diagrams

It is permissible to use a side or bottom connection to the pipeline.

Figure 4 shows the worst of all options. In this case, the heat transfer will decrease by 20 - 30% with the number of sections up to 6 pcs. inclusive. The more sections, the more losses will be.

Important operating rules

Daily operating rules do not imply a large number of technological operations.

The plant recommends:

- remove air regularly or if necessary using a special valve;

- do not use aggressive liquids as additives to the coolant;

- open shut-off and control valves sharply to avoid water hammer, which adversely affects the connections.

The manufacturer has placed special requirements for operation in a separate section of the instructions. It is strictly forbidden to:

- strike and apply physical activity that can destroy the product;

- allow freezing of water circuits;

- connect the elements of the ground loop to the radiator;

- use untreated water or liquid from external and underground sources;

- install the radiator in rooms with constant humidity above 75%, for example, in swimming pools;

- remove water from the circuit in the summer;

The radiator must not be installed in the hot water supply system of apartment buildings, for example, as a heated towel rail.

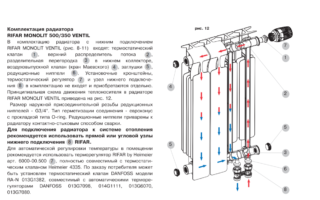

Types and equipment of radiators Refart Monolith

Models are available with nozzle spacing of 350 and 500 mm. This corresponds to the dimensions of the vast majority of radiators on the market today and previously used.

To replace old equipment, you do not have to make changes to the design of the supply pipes, which means that you can replace the battery using a minimum set of tools.

The RIFAR MONOLIT package does not provide any additional accessories. In this model, lateral connection to ½ or ¾ ”nozzles.

Plugs, air vents and brackets are also available at an additional cost.

The RIFAR MONOLIT 500/350 Ventil version allows connection according to diagrams 6 and 7 from the picture above. Products are produced only by special order of installers or retail chains.

This equipment includes, in addition to the radiator itself:

- thermostatic valve (temperature controller);

- flow distributors (top and bottom);

- reducing nipples;

- drain valve (Mayevsky);

- plugs for unused outputs.

Brackets are not included.

When ordering / buying, attention is paid to the direction of the connection (right or left). This information is essential for the correct operation of the radiator.

The innovative Rifar Monolith batteries are an excellent solution for creating heating systems operating at unstable pressure and temperature. Installation is simple and accessible to the user with minimal skills.