Effective thermal insulation of building structures is one of the prerequisites for maintaining a comfortable climate in residential buildings. Many technologies are known that involve the use of a wide variety of insulation materials for these purposes. It is possible to successfully cope with this task if high-tech substances with a high rate of thermal insulation are used. One of these materials is wood concrete.

Performance characteristics

Serial production of wood concrete blocks is based on the use of a special binder - Portland cement grade M400 or M500. In addition, the mixture includes wood filler (chips or sawdust), the proportion of which reaches 90 percent. For its mineralization, a little calcium or aluminum sulfate is added to the prepared solution.

These substances accelerate the hardening processes of the cement-wood mortar. Thus, shredded wood occupies almost 90 percent of the obtained insulation material. Therefore, arbolite blocks in their thermal insulation characteristics are more reminiscent of wood than concrete.

Advantages and disadvantages

The advantages of this class of insulation material include:

- low thermal conductivity, which allows you to save on the used building material;

- high strength indicators;

- good sound insulation characteristics;

- light weight and ease of installation;

- environmental friendliness.

In terms of its strength characteristics, this insulation resembles building blocks based on foam and gaseous substances. Because of the wood included in its composition, arbolite is more plastic. At significant loads, it does not crack, but only deforms, which is an indisputable advantage when compared with other materials.

Among the disadvantages of heaters of this class are noted:

- the impossibility of equipping them with a powerful reinforcing belt and floors;

- flammability - with prolonged contact with fire, it is charred and deformed;

- high level of hygroscopicity - the material absorbs up to 80 percent moisture by volume.

The water accumulating in the pores freezes in winter, after which the blocks are deformed and fall apart.

Materials and equipment for manufacturing

To make wood concrete with your own hands, you will need the following equipment and consumables:

- device for cutting raw wood (wood chip cutter);

- bins for chips and cement;

- containers for loading chemicals and water;

- forms for pouring liquid composition;

- drying chamber;

- wood blanks;

- chemicals and astringent additives;

The listed components and equipment are enough to start producing wood concrete blocks with your own hands in significant volumes.

Block making technology

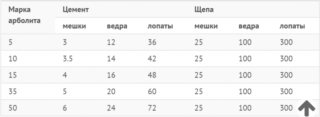

The independent production of wood concrete slabs according to the technological plan begins with the cutting of raw wood chips, after which it is allowed to lie down in a mixture with chemical reagents.Wood chips are cut exactly in their raw form, which allows them to give them the desired shape, and then provide the ability to remove tree sap. The production of wood concrete is strictly normalized, as a result of which one cubic meter of the received raw material will require:

- 8-10 kg of chemicals;

- 250 kg of cement;

- 250 kg of raw wood chips.

When kneading, the chips are moistened in such a way that moisture is not released, and the raw material itself is covered with a layer of cement that connects the fragments to each other. Subsequent tamping will clog the pores of the molded blocks, which gives the finished structure the desired density.

Compliance with chemical recipes

In correctly manufactured blocks, the ratio of components is set very precisely and cannot differ greatly from the norm. This mainly concerns cement and chemical additives that determine the quality of the resulting composition. For this purpose, sugars are washed out of wood by mixing with the following reagents:

- sulphate aluminum;

- calcium chloride;

- sodium silicate (its other name is "liquid glass");

- slaked lime.

As a result of treatment with reagents, the pores of the wood are filled with these compounds, excluding the possibility of water absorption.

Organic ingredients

The function of an organic filler, in addition to wood chips, is often performed by plant structures, the grinding of which results in needle-shaped fragments. In this capacity, the following are often used:

- pruning branches;

- wood twigs;

- branches together with leaves.

To maintain the required proportions for making wood concrete at home, straw, hay and sawdust are often used, which are added in the required quantities.

Manufacturing conditions

When making blocks, the solution is poured into pre-prepared molds by hand using a shovel and an ordinary bucket. The rammer for the poured mixture is made from a bar of a suitable size and is used only when the container is filled with a composition with a small slide. Do not tamp the mortar after the formation of each next layer. This method of laying allows you to get a homogeneous mixture of high quality.

The ramming of not yet fully completed forms for wood concrete is unacceptable, as this leads to delimitation of layers and poor adhesion. After completing the operations, the prepared mixture is allowed to settle in the mold for 2-3 days. Next, the formwork is dismantled, the finished blocks are laid out in the open air for drying. If funds are available, expensive vibration equipment can be purchased that allows the material to be compacted directly in the molds.

The purpose of wood concrete blocks

Depending on the area of use at construction sites, wood concrete insulation blocks are divided into two types - heat-insulating and structural modules. According to the accepted classification, the defining feature is the material density indicator. When constructing load-bearing walls of buildings, for example, it is not allowed to use blocks with a density below 500 kilograms per cubic meter. Samples with lower values are only suitable for thermal insulation of external walls in houses with load-bearing structures that take the load from floor and roof elements.

Structural material of this class is used in private construction for the construction of low-rise buildings. In addition, a wide range of block blanks of various shapes and sizes are made from it. In some countries, wood concrete blocks are used in the construction of industrial facilities and multi-storey residential buildings. A number of manufacturers use them to make foundations for small structures like garages or utility buildings.In addition, wood concrete mixture is often used to insulate frame buildings and fill the walls of wooden or reinforced concrete wells.