Uniform heat distribution is one of the defining tasks in the design of a heating system. A number of methods can be used to solve it. However, the most productive collector for heating a house with your own hands remains: schemes, varieties and correct installation will help to put this into practice.

Features of collector heating

The main difference between the collector and the traditional way of distributing the coolant is the separation of flows into several independent channels. In this case, various types of heating collectors are used, differing in configuration and size.

The design of the distribution manifold (this is what a welded manifold for heating is sometimes called) is quite simple. Several nozzles are installed in a square or round pipe, which are connected to separate heating circuits. The collector itself is connected to the central pipeline.

In the future, with the help of shut-off valves, it is possible to regulate the level of the coolant inflow into individual heating circuits. In this case, you can make a distribution heating manifold with your own hands, or purchase a ready-made structure.

The operational features of heat supply using a distribution manifold are as follows:

- Uniform hydraulic and temperature distribution... Even the simplest ring heating manifold for two or four circuits can effectively stabilize the system;

- Adjustment of heat supply operating modes... This is done using special components - flow meters, mixing units and thermostats. But before installing them, the correct calculation of the collector for heating is necessary;

- System maintainability... To carry out repair or maintenance work, you do not need to turn off all the heat supply in the house. It is enough to pre-install the heating manifold with flow meters and shut off the hot water flow to a certain circuit using the shut-off valves.

But heating with collectors has a number of disadvantages. First of all, this is an increased pipe consumption. The increase in hydraulic resistance is compensated by the installation of a circulation pump. It is mounted on every manifold in the system. Also, the steel collector for heating can only be used for closed systems.

Collector distribution of the coolant is important for houses with a large area. In this way, the gradual cooling of hot water, inherent in classic two-pipe and one-pipe schemes, is compensated for.

Types of collectors for heating

Before making a heating system manifold with your own hands, you need to decide on its functional load. This design can be installed in several heating points. Its equipment, overall dimensions and level of work automation will depend on this.

Before assembling the heating manifold, its calculation is performed, the installation location is determined. In fact, two structures are required for the system to work. The comb from the supply pipe distributes the hot coolant to the heating circuits.Return polypropylene collectors for heating are a collection point for cooled water for its further transportation to the boiler heat exchanger.

A home-made heating collector may be needed in two cases - for a water-heated floor system or when organizing traditional heat supply with radiators. They differ in size and configuration:

- Boiler room scrapers... For this, welded heating collectors are used, made of pipes of large diameter up to 100 mm. Circulating pumps and control valves are installed in the feed manifold. To complete the return ring heating manifold, cut-off ball valves are used;

- Combs for underfloor heating... In addition to the components described above, a mixing unit is used. It allows you to save the consumption of the coolant. Additionally, the use of a heating manifold with flow meters is recommended.

Each option has its own installation scheme and operating rules. Correct installation of the heating collector is carried out only after a detailed calculation of all heat supply parameters. Another difference is the number of circulating pumps installed. In the boiler room comb, each circuit is completed with them. For the local view of the heating collectors in the underfloor heating system, only one pump is provided for installation.

The material used for the manifold may differ from the piping. In this case, the correct connection of the heating manifold is done using special adapters.

Calculation of the heating manifold

Before the independent manufacture of a distributor manifold, it is necessary to perform calculations of its main parameters. These include the length, cross-section of the connected branch pipe and the number of heat supply circuits. In this case, the calculation of the heating distribution manifold can be done independently, or using specialized programs.

The main condition is the observance of the hydraulic balance in the structure. In the do-it-yourself heating distribution manifold, the throughput of the connected branch pipe must be equal to the sum of the same characteristics of the heating circuits. In practice, this can be achieved by summing the cross-sections of the nozzles. The result should be equal to the section of the main pipe that connects to the supply line. This can reduce the likelihood of imbalance in the system.

To optimize the place, they often make do-it-yourself heating system collectors in a single housing. This makes it possible to reduce the labor intensity of the work, and also contributes to the better functioning of the heat supply. However, the minimum distance between the supply and return pipes must be six diameters.

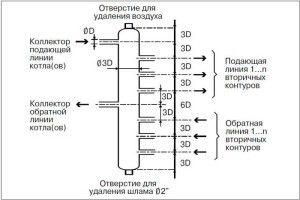

For further calculations of the collector for heating, the rules of 3 diameters can be used. It consists in the fulfillment of the following conditions:

- The distance between the inlet outlet groups of the comb should be 6 diameters;

- The cross-section of a steel or polypropylene collector for heating is equal to 3 diameters of the branch pipe connected to the system;

- The remoteness of the heating circuits is equal to 3 diameters;

It is also important to choose the right circulation pump. This primarily concerns its performance. Before installing the heating collector, the specific water consumption in the system is calculated and the pump is selected according to the results obtained. For complex circuits with several collectors, this procedure should be done for each circuit separately and for the entire system as a whole.

To make a homemade heating manifold, you can use pipes with a square, rectangular or round cross section. This will not affect the operation of the structure, and will not increase the hydraulic resistance. It is compensated by the work of the circulation pump.

Complete set of heating collectors

After performing the calculation, it is necessary to select the appropriate configuration for the distribution manifold. In order to properly assemble the heating manifold, you should take care of the required elements in advance.

In the minimum set for a steel heating manifold, it is enough to install shut-off valves. But in this case, there will be difficulties with adjusting the power of the hotel heating circuits.

Therefore, taps with a stem are installed in the feed comb for the boiler room, with which you can smoothly regulate the flow of the coolant. Additionally, flow meters are installed on the return manifold.

When calculating the heating manifold for a water floor, a different configuration is taken into account. It should consist of the following elements:

- Control valve... They are mounted on the branch pipes of the mains. With it, you can partially or completely leave the flow of hot water. When making a collector of a heat supply system with your own hands, it is recommended to use automatic models similar to thermostats;

- Flow meters... These components are installed on the return manifold. Their function is similar to control valves. The difference in the operation of the heat supply collector with flow meters is to limit the flow of the coolant into the return pipe;

- Mixing unit... An obligatory component for a water-heated floor. It mixes streams of hot and cooled water, thereby optimizing the temperature regime of the heat supply.

Despite the differences, all types of collectors for heating have one thing in common - they ensure the stable operation of the system. You can make such a structure yourself, or by purchasing a ready-made factory model. The latter option is acceptable if an annular heat supply collector is required for the underfloor heating system. When organizing heating with combs, it is best to make them yourself. Thus, it is possible to adapt the design to the specific parameters of the heat supply.

During the assembly of the heating manifold, you can use the servos that are connected to the electronic control unit. With their help, the system will work automatically.

Self-made collector

For the manufacture of a distribution manifold, a diagram is drawn up, which takes into account all the materials used. The rules for calculating the dimensions of the structure were mentioned above. But besides them, it should be borne in mind that the material for making the heating distribution manifold with your own hands will have to withstand all types of load - temperature and pressure.

It is best to use a square tube as a starting material. This applies to steel heat collectors. It is easier to process - the labor intensity of the process of installing the nozzles is reduced. The shape will not affect the operation of the heating system.

It is only important to correctly calculate the collector for a specific heating, taking into account all factors. For the traditional scheme, it is best to make steel structures, since they have a long service life and are less susceptible to breakage than polymer counterparts. Both polypropylene collectors for heat supply and steel ones are successfully used in a water-heated floor.

The procedure for manufacturing a distribution manifold.

- Cutting blanks... First of all, you need to make the main body and the pipes for it.

- Assembling the structure... To make a steel homemade collector for the heating system, you will need a welding machine. The connection of the branch pipes in the polypropylene analogue is carried out by means of temperature welding.

- Design check... To do this, it is necessary to fill it with water and create the maximum allowable pressure that can be in the heating.Leaks are not allowed.

Often they refuse to make a welded collector for heat supply on their own. This is due to the lack of an appropriate tool. An alternative manufacturing method is the purchase of separate components. It is best to choose items from a single manufacturer. Thus, the reliable operation of the structure can be ensured.

When manufacturing a polypropylene comb, it is desirable to use large diameter pipes. They must have a reinforcing layer. Otherwise, thermal deformation is possible.

Installation of the collector in the heating system

Before installing the heating manifold, its tightness and reliability are checked again. Installation is carried out according to a previously drawn up scheme. The conditions for connecting the structure to the heating system depend on the material of the comb.

It is important not only to make the correct design, but also to correctly connect the heating manifold. The mounting technology depends on the type of equipment used. In addition to maintaining the level during installation, the following nuances must be taken into account:

- Electric and gas boilers. They will connect to the upper or lower branch pipes;

- Circulation pump. It is installed only from the end of the structure;

- Heating circuits. Connected at the top or bottom of the manifold;

- Indirect heating tanks and solid fuel boilers are installed only in the side.

For a warm water floor system, a protective box must be provided in which the collector will be located. Without it, the likelihood of damage to individual components increases.

It should be remembered that even with minor violations in the process of manufacturing the collector, the chance of malfunctioning of the heating system increases. Therefore, after installing the comb, it is recommended to carry out a series of trial runs of heating in order to timely identify the obvious and hidden deficiencies of the system.

In the video, you can see an example of a homemade heating manifold: