Heat exchanger (TO) is a device that transfers heat between environments with different temperatures. Such equipment is used in industry, heating, air conditioning and ventilation systems. The simplest example is a room radiator, it heats up from a heat-transfer fluid and provides heating of the room in which it is located.

Heat exchanger structure

The equipment consists of a fixed and a movable plate, each with holes for the movement of the medium. Many other smaller minor ones are installed between the main plates, so that every second of them is rotated to the neighboring ones by 180 degrees. The secondary plates are sealed with rubber gaskets.

The second important element of maintenance is the coolant. It flows through corrugated stainless steel channels. Cold and hot media move on all plates, except for the first and the last, simultaneously, but from different sides, preventing mixing. At a high flow rate of water in the corrugated layer, turbulence arises, which increases the heat exchange process.

The device is connected to the pipeline using holes on the front and back walls. The coolant enters from one side, passes through all channels and leaves the equipment on the other. The inlet and outlet openings are sealed with a special gasket.

The channel plates are a very important maintenance element. When choosing a heat exchanger, its performance must be taken into account. The higher the requirements for the equipment, the more plates must be in it. Their number is responsible for the overall efficiency of the device and the ability to heat a particular room.

Types of maintenance

According to the principle of operation, the equipment is divided into recuperative and regenerative. In the first, moving heat carriers are separated by a wall. This is the most common type, it can be of various shapes and designs. In the second case, hot and cold coolants come into contact with the same surface in turn. The high temperature heats up the wall of the equipment during contact with the hot medium, then the temperature is transferred to the cold liquid upon contact with it.

By purpose, maintenance is divided into two types: cooling - they work with cold liquid or gas, while cooling the hot coolant; and heating ones - interact with a heated medium, giving energy to cold streams.

By design, heat exchangers are of several types.

Collapsible

They consist of a frame, two end chambers, separate plates separated by heat-resistant gaskets and fixing bolts. This equipment is easy to clean and can be more efficient by adding plates. But collapsible TOs are sensitive to water quality. To extend their service life, the installation of additional filters is required, which increases the cost of the project.

Lamellar

They differ in the method of connecting the inner plates:

- In brazed TO, corrugated stainless steel plates with a thickness of 0.5 mm are made by cold stamping. A gasket made of special heat-resistant rubber is installed between them.

- The welded plates are welded together to form cassettes, which are then assembled inside the steel plates.

- In semi-welded TO, cassettes are fastened by means of paronite joints in a structure of a small number of welded modules. These modules are sealed with rubber gaskets and laser welded together. Then they are assembled between two plates using bolts.

Plate heat exchangers are used in environments with high pressures and extreme temperatures. These devices require minimal maintenance, are economical and highly efficient. In addition, the efficiency of the equipment can be increased or decreased as needed by increasing or decreasing the number of steel plates.

The only drawback of a corrugated stainless steel heat exchanger is its sensitivity to the quality of the coolant; it is necessary to install additional filters.

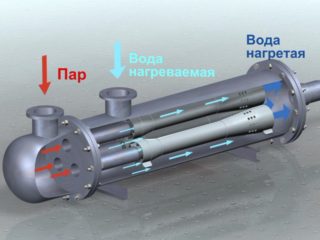

Shell and tube

They consist of a cylindrical body, where bundles of tubes are placed, assembled into lattices. The ends of the pipes are fastened by flaring, welding or brazing. The advantage of such equipment is that it is undemanding to the quality of the coolant and the possibility of using it in technical processes where aggressive media and high pressure are present (in the oil, gas, chemical industry). The disadvantages of shell-and-tube maintenance are relatively low heat transfer, large dimensions, high cost and difficulty in repair.

Spiral

They consist of two sheets of metal rolled into a spiral. The inner edges are connected by a partition and secured with pins. These heat exchangers are compact and self-cleaning. They are able to work with liquid inhomogeneous media of any quality. With an increase in the speed of fluid movement, the intensity of heat transfer increases. Disadvantages: difficulty in manufacturing and repair, limiting the pressure of the working fluid to 10 kgf / cm².

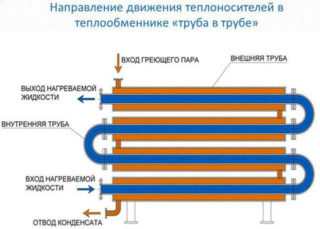

Double pipe and pipe in pipe

The first ones consist of pipes of different diameters. Liquid and gas are used as a heat carrier. The devices are used in places with high pressure, have a high level of heat transfer. They are characterized by simplicity of installation and maintenance. The only drawback is the high cost.

A pipe-in-pipe heat exchanger consists of two pipes of different diameters connected to each other. They are used at low flow rates and to equip a chimney.

The type of operation depends on the type of device. From the design of the equipment - the efficiency during operation in certain conditions. Therefore, sufficient attention should be paid to studying the features of each type of equipment.

Making a heat exchanger with your own hands

To do the maintenance yourself, you need to have certain knowledge and skills. To begin with, it is worth determining what requirements the equipment must fulfill, the version of the device depends on this. It is necessary to calculate the materials and make a drawing of the future maintenance

The bathhouse is a place where it is often necessary to make a homemade heat exchanger. Since a conventional furnace with a firebox heats a limited volume of liquid, a water submerged twisted TO may be necessary. It is designed to heat more water. A coil is lowered into the tank with a heated coolant, water passes through it.

When it is necessary to keep the water in the tank hot, the tank is connected to the heating boiler using two supply and return pipes.

Water-water

To make a water-water heat exchanger with your own hands you will need:

- A stainless steel container with a height of 50-60 cm and a diameter of 30-40 cm. Ordinary steel can also be used, but it must be protected by a durable polymer coating.

- Tank lid.

- Copper tube about 10m.The length is taken from the calculation: for each turn of the spiral with a diameter of 30 cm, approximately 1 m of the tube goes. Better to take with a small margin.

- Welding machine for stainless steel and copper brazing.

- Protective equipment: gloves, welding mask.

The work is carried out in the following order:

- A lid for the tank is made and its strong sealed fastening is ensured. It cannot be welded, because it must be removed to enable cleaning of the inside of the container. The most convenient mounting option in this case is flanged. It can be ordered immediately along with the tank, or you can make it yourself. The number of holes is calculated taking into account the location of the seal, usually 4 or 6 fasteners.

- Next, an inlet for cold water is created at the bottom of the container and an outlet for heated water in its upper part in the side wall. Threaded adapters are welded into the holes to connect the pipeline. It should be possible to remove the structure for washing or repairing it.

- The next step is to make a copper coil. If the tube is soft, it can be easily wound with a mandrel. If it is tough, you must use a burner. Fittings are welded to the free ends. They are passed through holes in the lid. It is important to monitor the tightness of the soldering, because hot water piping will be connected to the adapters.

- The final stage will be the assembly of the heat exchanger. For this, a lid with a copper pipe spiral and a rubber seal covers the tank. Flange mountings are tightened with bolts. In this case, it is necessary to ensure that the spiral is strictly in the middle of the container, without touching the walls. Otherwise, the effectiveness of maintenance will greatly decrease.

The considered option is also suitable for heating water in private houses. Such devices operate on the principle of natural circulation: a wood or gas boiler heats up water, it rises up the supply pipe, gives off heat and goes back down. Then the process is repeated.

It is not always possible to ensure constant natural circulation. Therefore, it is better to use a circulating pump.

Air

The device consists of a body and pipes with a heated medium installed in it. Through them, the fan drives a stream of air to which heat is transferred. A heat exchange process takes place. This option is called a heater.

Also, plate structures are used for ventilation and air heating systems. There, corrugated metal plays the role of a heat transfer wall. Where two streams of air, cold and warm, move perpendicular to each other. They are separated by plates so that the warm and cold streams are alternately located in the gaps. The effectiveness of these devices is high, but they are difficult to make on your own.

Air maintenance installation procedure:

- The body is made of a sheet of metal. The area of its bottom should be equal to the size of the fan. For a centrifugal design, a box with an area of 70% larger than the outlet pipe is taken.

- Holes for a copper tube are drilled in the walls of the box on opposite sides.

- Prepared pipe sections are installed in the holes made so that their edges extend beyond the box by 2 cm on both sides.

- Angle fittings are welded to the free ends of the tubes. They are connected in the form of a snake. You can make two parallel ones. So the coolant will cool less when blowing.

- Threaded adapters are soldered to the output and input ends, and the water supply is connected to them. Water is supplied, check that the connections are tight.

- The case is mounted on a base with a fan. The structure is closed with a casing so that the air flow does not go to the sides.

To make a heat exchanger for heating a private house with your own hands, it is necessary to understand the principle of its operation, to make an accurate calculation of the required power for sufficient heating of the room, especially in winter.You need to use the most heat-conducting materials, copper is the best option. It has an efficiency far superior to other metals. All actions during the manufacture of maintenance should be performed carefully, avoiding the ingress of foreign objects inside. If there is self-doubt, it is better to turn to an experienced master. He will perform the connection of all elements efficiently and tightly.