The main element of any of the heating systems is a special device - a heat exchanger for heating a house, in which heat is transferred from the heat generator to the coolant. A large number of different heating boilers are presented on the modern market, but all their variety does not limit the imagination of home craftsmen in terms of independent production of such devices. In our article, readers will be asked to find out what a heat exchanger is needed for in a heating system, how to make it yourself and how to connect it.

Heat exchanger function in the heating system

In home air heating systems, surface heat exchangers of the heating system are most often used, where heat energy is transferred through the surfaces of the metal walls of the device.

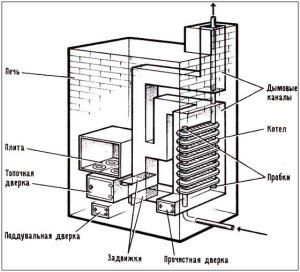

The principle of heating through a heat exchanger is most fully implemented in the design of gas, solid fuel or electric boilers. The water circulates through the pipes bent in the form of a coil, installed inside the heating unit, and is heated by the temperature of the burning fuel. The heated coolant goes into the heating system pipeline, and cooled water from the radiators enters the heat exchanger to replace it.

Until now, in many individual houses, the stove remains the traditional source of heat. It is good for heating a small hut, but in a multi-room cottage, its thermal power is insufficient. Therefore, in a private house, a heat exchanger in the heating system is needed in order to turn the stove into a full-fledged water heating boiler. The size and shape of a homemade heat exchanger for heating should fit into the dimensions of the fuel chamber of the furnace. Pipes and radiators can be connected to this device, and then the heating of the house will become more efficient.

Types of heat exchangers

Water heat exchangers for heating are more practical. This is due to the fact that water transfers heat energy much better than air. However, an air heat exchanger for heating is also used. In addition to water and air, a heat exchanger is also used for the chimney for heating, which is installed not inside, but outside.

All industrial heating devices are equipped with heat exchangers, the design of which is maximally adapted for efficient water heating.

At the factory, heat exchangers are made of copper. The pipe is a coil, across the bends of which there are many plates, which provide a large heat exchange area.

It's almost impossible to build a home-made heat exchanger for heating at home so that it is exactly like a factory one. Therefore, you will have to choose a simpler option.

System design

The principle of operation of a home-made heat exchanger is that the stove transfers energy to it from the combustion of wood or coal, and the heated water disperses through pipes to all rooms. This heating method allows the inhabitants of the house to enjoy an even distribution of heat. In addition, all rooms warm up much faster, and fuel costs are reduced.

There are two ways to improve stove heating of a private house:

- build a furnace "from scratch" for a specific size of the heat exchanger;

- install a home-made heat exchanger, made to fit the size of the firebox, into the existing furnace.

By making a heat exchanger for heating with their own hands, the homeowner can be sure that his stove with a water circuit will work no worse than a real solid fuel boiler. The only difference is that in the stove, the location of the inlet of the heat exchanger will turn out to be slightly higher above the floor than in factory boilers. This is a rather significant difference that can affect the rate of natural circulation of the coolant.

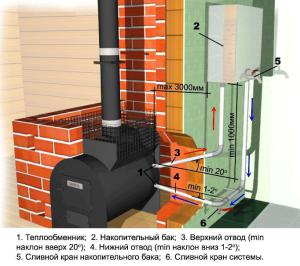

The connection of the heat exchanger to the heating system must be done in such a way that the cold water supply pipe (return) is located as low as possible.

Just like in a conventional heating system, an expansion tank must be installed at the top of the pipelines. It will compensate for the change in the volume of heated water and release air bubbles from the system. If heating through a natural circulation heat exchanger is insufficient to heat a large cottage, you will have to install a circulation pump in the system.

To connect a homemade heat exchanger for heating, 2 fittings are used: one at the bottom (cold water inlet), the other on top (hot outlet). When installing the heat exchanger, it is necessary to provide the necessary slope of the pipes, as required by the scheme.

Advantages of heating with a heat exchanger

If you understand why you need a heat exchanger in a heating system, you can see several clear advantages:

- Ease of manufacture. If a stove already exists in the house, then you will have to spend only on making a homemade heat exchanger and installing a heating system.

- Combined heating. In addition to heating the house from the surface of the stove, a water heating system will be added.

- Variety of fuels. You can heat the stove with any solid energy sources, in contrast to boilers that are focused only on a certain type of fuel.

- Nice appearance. It is useful to preserve the traditional look of the Russian stove when creating an interior in the national style.

Among the disadvantages of heating through a heat exchanger are: less high efficiency compared to factory boilers and the lack of automatic control over the intensity of heating of the coolant.

How to make a homemade heat exchanger

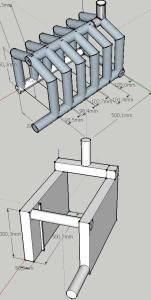

The shape of a heat exchanger for DIY heating can be different. The most common option is a register of several steel or copper pipes, but plate-type samples are also used.

The temperature in the combustion zone is very high, especially when coal is burning. Therefore, increased requirements are imposed on the metal from which the elements of the heat exchanger will be made, the rationality of its design and the quality of welds.

Materials for making

The task of water heat exchangers for heating is to provide optimal heat transfer, and in this process the degree of thermal conductivity of the metal is important. For example, a steel pipe conducts heat 7 times less than a copper pipe. Therefore, with the same pipe diameter, to transfer the same amount of heat, 25 meters of steel pipe will be needed instead of 3.5 meters of copper.

Copper heat exchangers are the most economical to operate, but also expensive. Heat exchangers made of a steel pipe with a diameter of at least 32 mm are considered more affordable for self-production.

If it is supposed to heat the stove with coal, it is better to install a cast iron heat exchanger. This metal is stronger, and the walls of the device will not burn out for a long time.

Heat exchanger power calculation

It is rather difficult to calculate in advance the capacity of a heat exchanger for a heating system. To do this, you need to take into account too many factors: pipe diameter, coil length, metal thermal conductivity, fuel combustion temperature, coolant circulation rate, etc. The real ability of a heat exchanger to cope with its functions will become clear only after the heating system starts operating.

When calculating, it can be guided that 1 meter of a pipe with a diameter of 50 mm, which serves as a heat exchanger, will give 1 kW of thermal power.

You can take, for example, any well-known boiler model and, in accordance with its parameters, make your own home-made heat exchanger.

Design features

A heat exchanger for water heating of a house, welded from smooth-walled pipes, is called a register. It looks like a kind of "grill" and is the most popular form of homemade heat exchanger. In addition to this design, simpler devices are made in the form of a rectangular or cylindrical tank. The main thing is that the surface area for heat exchange is as large as possible.

When making a heat exchanger with your own hands, several conditions must be observed:

- the width of the internal voids in the heat exchanger must be at least 5 mm, otherwise the water in it may boil;

- the wall thickness of the pipes must be at least 3 mm so that the metal does not burn out;

- a gap of 10–15 mm between the heat exchanger and the walls of the furnace must compensate for the expansion of the metal during heating.

Installation features

The easiest way is to install the heat exchanger simultaneously with the construction of the furnace. If you install it in an old oven, you will have to disassemble part of its brickwork.

Procedure:

- On the prepared foundation of the furnace, a tubular heat exchanger is installed directly into the cavity of the furnace.

- With the further laying of the rows of bricks, space is left for the inlet and outlet pipes of the device.

- After completing the laying of the furnace, the heat exchanger is connected to the heating system, the system is filled with water and a test furnace is fired.

The video material invites you to familiarize yourself with useful tips for making a heat exchanger yourself:

Until now, we have only talked about heat exchangers in a hot water heating system. Let's pay attention to other areas of their application.

Air heating

If we characterize the air heating system, we can say that it has more disadvantages than advantages. Air heat exchangers for heating are not widely used in the private residential sector, they have not yet become commonplace.

The advantage of this system is the ability to combine heating with forced ventilation. However, possible errors in its design and installation can minimize the benefits. Fan noise can be heard in the air ducts, and temperature imbalances are felt in rooms.

Heat exchangers for air heating exist for direct heating as well as indirect. In the first of them, gas or diesel fuel is burned directly in the heat exchanger itself. Other models use an intermediate heating medium.

Chimney heat exchanger

At the dachas and in the baths of the "folk craftsmen" you can see a homemade water or air heat exchanger installed on the chimney of a small stove. It turns out very profitable: the heat does not go away with the smoke, and part of it is used to heat the water.

By installing a heat exchanger on the chimney for heating, you can get a fairly large amount of hot water. Of course, this is not enough to heat the whole house, but it is enough to put one or two radiators in the dressing room. You can use a heat exchanger for the chimney both for heating and for quickly heating water in a bath.

Such a device can be very simple to manufacture. As a basis, you can take a piece of a large pipe with a diameter of 500-700 mm, or weld a stainless steel tank. In the center of the structure there will be a vertical pipe corresponding to the diameter of the chimney, and two pipes must be welded on top and bottom.

By giving its temperature to the heat exchanger, the combustion products leaving the furnace cool down quickly. Because of this, the draft in the chimney decreases and the combustion of fuel slows down somewhat.

Making a heat exchanger for heating with your own hands can be a way to arrange full-fledged water heating in a house without purchasing expensive equipment.

The idea with cast iron batteries is not bad, but what about rubber gaskets between the sections. In the firebox, they will burn, and in the chimney, if they do not burn, they will quickly dry out and crumble.