In the absence of heating the garage, it becomes uncomfortable to carry out repair work, moreover, low temperatures have a bad effect on the condition of the vehicle. Heating the garage will solve the problem. For this, you can use compact electric convectors or a high-performance boiler with increased power. The choice of equipment depends on the characteristics of a particular object, individual needs and financial capabilities of the owner.

Pros and cons of a heated garage

The advantages of a heated room include the following factors:

- Competently executed heating of a metal garage allows you to create comfortable conditions for repairs, which is important with frequent use of the premises.

- In a warm space, it is easier to start a car engine as the oil in the engine will not thicken.

- Due to the easy start of the motor, its parts are subject to reduced wear.

- Garage heating in winter allows you to wash your car without fear of freezing locks.

Heating arrangement has several disadvantages. These include a number of points:

- Obligatory costs for electricity or other fuels.

- Some types of systems are quite expensive to install and maintain; they only pay off after 4-6 years from the date of purchase.

- Increased fire hazard, the need to comply with a number of rules during installation.

An inexpensive solution is heating the garage with a solid fuel or gas boiler: the most economical way involves a minimum of costs during operation. Also, small equipment costs will be when heating with compact convectors: their price is very low.

Garage heating efficiency in winter

Before deciding what is the best way to heat the garage, it is required to take a number of measures so that heat loss is minimal, and during the operation of the equipment, the risk of fire is reduced to zero. To solve the first problem, it is important to insulate the room: expanded clay is suitable for the floor, basalt or mineral wool for walls and roofs.

It is required to close all the cracks, and also to perform a vapor barrier. To get rid of the risk of fire, it is necessary to consider the ventilation structure. It is advisable to make a forced draft, especially if the garage space will be heated by a boiler.

Heating methods

To heat the garage, you need to choose the optimal energy source and heat carrier. At the same time, the area of the room, its layout, the intensity of operation, the quality of surface insulation and other factors are taken into account.

Gas heating

Such an energy carrier is inexpensive, but the installation of the system is associated with additional costs. You will need to draw up a project, permits, pay for professional installation, arrangement of ventilation, get a regulation for the boiler. Gas heating can be fully automated, the system will always have a coolant, the operation of the equipment is characterized by efficiency and increased efficiency. The disadvantages of the system are the risk of fire, increased explosiveness, the impossibility of doing it yourself.For a garage, it is advisable to use a condensing steam-droplet apparatus that can work effectively at reduced pressure. As a source, you can use a standard gas cylinder of 20 or 50 liters.

Electric heaters

Often, floor or wall convectors are used to warm up the garage space. They are distinguished by fast heating, automated operation, safety, long service life, versatility of use: such equipment can be used regardless of the level of atmospheric humidity and pollution.

The disadvantages of the electric option are the increased cost, not too economical energy consumption. In addition, the electric heater must always be connected to a 220 volt outlet. If the garage is not electrified, you will have to use generating equipment.

Solid fuel

A solid fuel boiler is a good solution for heating technical rooms and home rooms. It heats up quickly enough, it can work on wood, pellets, coal, an air circuit can be connected to it. However, the system requires the obligatory arrangement of a chimney to eject the waste, the equipment itself is quite cumbersome, the fuel must be regularly loaded into the combustion chamber.

The most popular are pyrolysis models of boilers, which are very energy-intensive and differ in a relatively simple connection diagram.

Water

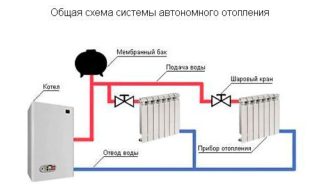

For such a system, a gas, solid-fuel unit or an electric boiler is used; diesel or antifreeze can also be used as fuel. The installation of the structure can be done independently, since its structure is simplified. For this, classic round and shaped pipes are used, the temperature of the coolant can be changed using a special regulator. If the room is located at a maximum of 20 m from a residential building, you can connect the system to heating equipment for living rooms.

Air heating

This is a good solution combining heating and ventilation functions. For such a system, you can use an autonomous heater: for a compact garage, for example, the Planar 8 DM 12 or 24 model is suitable. The main advantage of the system is a one-time drying and uniform heating of the full volume of air. As a result, there is no moisture in the room that can corrode metal parts or damage wooden elements.

Choosing the best option

To heat the garage, you should pay attention to the following subtleties:

- Room area, layout.

- Frequency of operation: for example, if the garage is planned to be used only 1-2 times a week, you can get by with a convector, and with regular visits, it is better to install a boiler.

- It is planned to heat the whole room or part of the garage.

It is important to take into account the financial capabilities of the owner, the availability of equipment, used fuel and coolant. Attention should be paid to the proximity of centralized communications: if they exist, you can connect as a source of energy.

DIY heating system organization

Before starting the installation process, you need to prepare a drawing, which will display the components of the system and fix the subtleties of the connection. If we are talking about gas heating, you will need to collect a package of documents, otherwise the design may be recognized as illegal. Then you need to pick up the equipment itself. For this, it is important to take into account the power by making a calculation by area, the heating rate, efficiency and other factors. After that, boiler equipment, pumps are installed, ventilation is arranged, pipes are laid and devices are connected to each other.Then, commissioning is carried out, which makes it possible to check the serviceability of the devices, make sure of the correct choice of power and, if necessary, eliminate the mistakes made.

If you plan to use the garage space relatively rarely, it is permissible to install floor or wall convectors by connecting to the power supply. If there is no central outlet, a petrol or diesel generator can be used.

If we are really talking about a metal garage, then you should not make a warm room out of it. Such measures will never pay for themselves. And at -40 degrees, even more so. Only spot heating of the engine area, namely its crankcase, will help here. And the safest and most economical heating means can be a ceramic heater. Firstly, it is flat, and can easily roll under the crankcase of any car on simple wheels (if you attach the handles). Moreover, it is safe, even if oil from the engine gets on it, it will not ignite.

Yes, the engine does not heat up to 40 degrees, but an easier start of the car in the winter cold will be provided. And most importantly, a warm individual garage is a direct road to corrosion of the body of your car. After all, after driving into a warm garage, the body begins to “cry and rust until the morning.