Wood walls are distinguished by their ability to retain heat for a long time. But despite this, they also need additional insulation, since the tree shrinks during operation. The outer insulating layer protects the house not only from the cold, but also from mechanical influences, fungi, rodents and insects. To create high-quality thermal insulation, you should understand in advance the types of insulation and their features. There are many types of materials, as well as manufacturers (penoplex, polystyrene and others). Each has its own positive and negative traits.

Features of the insulation of wooden houses

Wood absorbs liquid. To reduce this property, it is treated with special water-repellent agents. If the house has adequate ventilation, water will not have a negative impact. If the air exchange is disturbed, condensation will accumulate, which leads to the swelling of the tree and the appearance of fungi and mold.

During installation, several requirements must be observed:

- damp walls cannot be insulated;

- there must be vapor permeability;

- thermal insulation must be sheathed with a membrane on both sides;

- it is necessary to leave a distance between the insulation and the final finish.

If the walls of the house will be painted, you should buy paint and sealant with a good level of vapor permeability. Before work, the surface must be cleaned of dirt, moss, hooks, bugs and other pests.

Types of wood insulation

The range of insulation materials is quite wide, but not all materials are vapor-permeable. Insulation materials based on mineral wool, ecowool or cellulose are suitable for wood. The choice of the right insulation depends on many factors.

Stone wool

It is made from rocks, in particular basalt. In addition to stone fibers, the material contains binders and hydrophobized additives. The material is non-combustible and can withstand temperatures up to 600 ° C, which is especially important for wooden buildings. It has low thermal conductivity and a high level of vapor permeability. Release form - plates, mats coated with foil, kraft paper or fiberglass.

Installation of basalt slabs is not difficult, so you can do it yourself without the help of specialists. They retain their shape well during operation and do not shrink during installation according to all requirements. The weight of the slabs is low.

Among the disadvantages are the fragility of the fibers and the high cost. It is possible to work with such products only with the use of personal protective equipment and in a respirator, since small particles can enter the respiratory tract.

Slag wool

Outer insulation is made from blast-furnace slags - metallurgical waste. Thanks to this, the cost of the insulation is low, and the maximum temperature is 300 ° C. Release form - rolls and plates. Usually, a foil coating is made. The rigidity is low, so the material can be used to insulate curved surfaces. It retains heat well, absorbs sound. Prevents mold growth. Rodents and insects also dislike this stuff.The service life is about 50 years.

Slag wool does not tolerate temperature fluctuations; when wet, it releases acid, which corrodes the metal. The fibers are sharp, so when styling, be sure to use protective equipment so that the material does not get on the skin and does not cause irritation.

Glass wool

The material is distinguished by its strength, elasticity, and a high degree of noise insulation. It is produced from glass breakage melts, to which limestone, borax, dolomite and other components are added. Polymers, sometimes bitumen, act as a binder. Elasticity is achieved through long fibers.

Glass wool has a good vapor permeability and keeps heat well from the inside. It is not adversely affected by aggressive chemicals. Differs in non-combustibility and the ability to keep heating up to 450 ° C. Release form - plates, rolls, mats coated with foil and fiberglass.

The main disadvantage is fragility and stinging. It is imperative to work in protection for hands, eyes and respiratory tract. Protection must be strong and reliable, as ordinary clothing will not save you from glass wool. The respirator will allow you not to breathe dust particles that are formed during styling.

Ecowool

Cellulose insulation or ecowool is a material that is made from waste from the paper and cardboard industry. To improve performance, manufacturers add antiseptics and flame retardants to fibers. Ecowool absorbs moisture and gives it away without changing its characteristics. Prevents condensation formation. Absorbs sound and vibration. Does not emit harmful substances. Insects and rodents do not start in ecowool.

The main disadvantage is the styling technology. To work with ecowool, you need skills and abilities, so you need to call a specialist.

Thermal insulation process with mineral wool slabs

Any home craftsman can make independent insulation of the walls of a wooden cottage with mineral wool. For work, you will need a high-quality reliable tool and consumables:

- pencil for creating markings;

- level;

- ruler, tape measure;

- jigsaw;

- fasteners (screws and dowels);

- antiseptic for walls;

- membrane for hydro and vapor barrier;

- construction stapler;

- acrylic based sealant.

Next, you need to calculate the volume of materials. For this, the area of the walls is calculated, from which the area of the openings is subtracted, and divided by the area of one slab. The resulting value will be the minimum required number of plates. It is better to buy them with a margin, so that in case of damage you can replace them with a suitable one. If installed in two layers, the value should be multiplied by 2.

Preparation

Before starting work, you should prepare the wooden surface. To do this, it is eliminated from defects and treated with an antiseptic. Installation can be started only after complete drying.

Insulation can only be done in warm weather, so that the walls are not damp or frozen. It is necessary to carefully inspect the seams between the joints and, if there are voids, seal them with a sealant. Similarly, get rid of old cracks in the tree.

The primer should be applied with a brush, working out all irregularities and depressions. Can be applied in two coats if the wood absorbs the composition quickly. You need to wait until the logs are completely dry, after which you can insulate a private home.

Installation of insulation

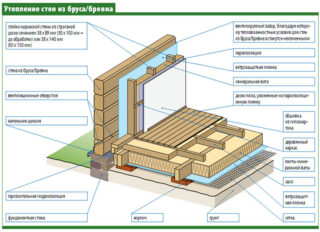

- Fastening the vapor barrier layer. The membrane is laid in horizontal stripes from the lower parts of the walls. Fixation is done on a stapler.

- Installation of extreme beams in level at a distance of 5-10 cm from the corners. Fixation with self-tapping screws. The rest of the parts are fixed in such a way that the distance between them is 10 mm less than the width of the insulation material.

- Mineral wool slabs are placed in the lathing cells without gaps. They are fixed with dowels.The second layer is laid in such a way that the joints between the slabs on the first layer are overlapped.

- Fastening the protective membrane. It is installed on staples. Care must be taken to ensure that the material fits snugly against the base.

- Stuffing counter-lattice rails. They provide clearance for ventilation.

You can also use a frameless method of insulating a log house from the outside. With this installation, the guides are attached to the walls on U-shaped metal hangers. Holes for suspensions need to be made in the slabs. Additionally, the structure is fixed with dowels. A membrane is placed on top.

After all the work, you can finish the facade. Facade siding and other finishing materials can be installed on thermal insulation.

Ecowool laying

To lay the material on the walls, you must first make the markings for the lathing. The timber guides are laid vertically at a distance of 50-60 cm from each other. After that, you need to make a sheathing of moisture-resistant slabs at a distance of 80-100 cm from ground level. The lower part is sewn up with boards. Ecowool is unpacked and placed in a container. Beat it at a low speed with a mixer so that no lumps remain.

Insulation spills out between the walls and the plaster sheathing, filling in all corners. After that, the next row of cladding is attached. Then priming and finishing is done.

The most difficult thing is the distribution of ecowool in the upper part of the crate, so the work must be done carefully and carefully, trying to better compact the material.