For most car owners, it becomes especially important to decide how to insulate the garage from the inside with your own hands. This is due to the need to create comfortable conditions in the garage, as well as the desire to get rid of the condensate spreading dampness. High-quality insulation of the garage is impossible without first selecting suitable thermal insulation and mastering the technology for its installation.

Optimal temperature conditions in the garage

Before you insulate the garage from the inside with your own hands, you need to take into account that its metal walls are very thin; it makes no sense to heat such a room in winter. To create normal conditions, it is reasonable to insulate it using available methods and means.

The optimum temperature from the point of view of the safety of the car is +5 degrees. To maintain it in an iron garage, it will be necessary to arrange forced ventilation, providing an inflow of fresh air in a volume of at least 180 m³ per hour per vehicle. For the safety of the machine, it is not the absolute value of the temperature that is important, but the provision of conditions that guarantee low air humidity.

Excessive heating of internal spaces is more likely to harm, as condensation will appear on metal surfaces. In this case, competently organized ventilation plays an important role, excluding the possibility of the formation of harmful fumes. Therefore, motorists trying to increase the temperature inside the garage by plugging the vents are doing the wrong thing. It is they that allow you to maintain the microclimate necessary for a car. In addition, ventilation openings allow carbon monoxide to escape and reduce the likelihood of moisture build-up.

Technical parameters of materials for insulation

Before insulating the garage using available methods, you will need to choose materials suitable for these purposes. First of all, thermal conductivity is taken into account, which provides effective insulation of metal walls. The undisputed leader here is expanded polystyrene with a working indicator of 0.038 conventional units. Behind it are the following well-known insulation materials:

- mineral and glass wool (0.038 and 0.043 - respectively;

- expanded clay (0.171);

- foam concrete (0.28).

- ceramic brick (0.519);

- cinder blocks - 0.64.

A layer of expanded polystyrene with a thickness of 5 cm is equivalent to insulation from a meter-long cinder block covering.

Another important characteristic of the material chosen for insulating a garage is thermal inertia. This indicator takes into account the rate of temperature change on the surface of the protective coating. Here, the opposite is true - the wall of cinder blocks has a large inertia (it heats up and cools down longer). Thus, the correct approach to garage insulation is to choose a material due to which the thermal inertia of the protection increases and its thermal conductivity decreases.

Since such a heat insulator simply does not exist in nature, a combined approach has been invented, which allows not to let the cold into the interior spaces in winter, and to protect them from the heat in summer.For these purposes, modern technologies are used, involving the use of classic heaters in combination with reflective heat insulators. This approach is easy to implement if the garage is attached to the house, otherwise it is not as effective.

But even in an attached garage, wall insulation will be of little use if you do not worry about thermal insulation of the floor, roof and gate.

Types of heaters

Classic heaters for garages are traditionally selected from the following list:

- mineral wool materials;

- fiberglass heat insulators;

- polymeric protective coatings (polystyrene or polyurethane foam).

The main requirements for thermal insulation are a low level of water permeability, which ensures reliable protection of surfaces from excess moisture, as well as good fire resistance.

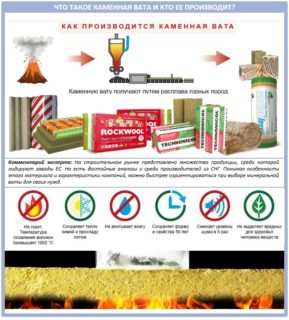

Mineral and glass wool

These inexpensive and popular materials are considered a good choice for insulating garage spaces as they provide reliable protection. However, they have an increased rate of hygroscopicity, therefore, their use is possible only on condition of preliminary waterproofing of structural elements. At the same time, the total cost of insulating it increases significantly.

Glass wool deserves special attention, which in terms of heat-shielding characteristics and price is comparable to its mineral analogue. However, to its disadvantages is added flammability and the need to protect against glass dust spread during the installation of insulation blanks. It is possible to protect the respiratory organs when working with glass wool by means of a respirator or a protective mask.

Styrofoam / expanded polystyrene

Using one of these materials is the best option for insulating a metal garage. With their undoubted advantages, they are practically devoid of disadvantages. Polyfoam and expanded polystyrene (PP) have excellent thermal insulation properties and are completely moisture-proof. They are bacteriologically stable - they do not spread fungi and do not rot. Due to the lightness of sheet blanks, they are easy to assemble and have a relatively low price.

The only drawback of insulating garages with foam is the flammability of the source material, which reduces the fire protection of the structure. However, there is a way out of this situation, which consists in the use of a special foam of the "PBS-S" brand. This type of insulation is processed with a fire retardant during production, which blocks the spread of fire.

Do-it-yourself wall insulation from the inside

The procedure for carrying out work is considered on the example of using foam (extruded polystyrene foam), which has all the qualities necessary for a heat insulator.

It is also allowed to insulate garage walls with this type of PP from the outside, this will require sheet blanks with a thickness of at least 20 mm.

The sequence of insulation operations:

- On the inner walls of the structure, a frame base (crate) is prepared from a wooden bar.

- The first layer of protective material is attached to it by means of a liquid adhesive composition.

- A second layer of insulation sheet is glued on top.

When installing the coating, it is important to observe the offset of the sheets laid in a staggered manner, which excludes the coincidence of the butt joints. Due to their reliable overlap, the insulation will be as effective as possible.

Insulation of garage doors

When insulating garage doors, the same technique is used as for protecting the walls of a structure. Work order:

- A wooden lathing is equipped, fastened on the base with self-tapping screws.

- The voids in the frame are filled with foam plates (a special adhesive is used to fix them).

- The joints between the sheets are glued with Izolon tape.

Decorating the gate with suitable finishing materials will help to give the gate an attractive look.

Roof insulation

If the garage is located separately from the residential building, in addition to the walls, the roof will also have to be insulated. Otherwise, the heated air will begin to rise and melt the snow, which will cause temperature differences and condensation. Accounting for the material from which it is assembled will help to determine the insulation. If a plank ceiling is made in the structure, foam plates are used, fixed by means of plastic dowels and covered from above with sheets of plywood.

If concrete slabs were used during the installation of the walls and floors of the capital garage, you will need to prepare a frame base from a metal profile. Its guides are attached to the base planes with self-tapping screws, after which the plates themselves are laid on the resulting frame. If all elements of the structure, including the roof, are assembled on the basis of corrugated board, they are insulated in the same way as for gates and walls of steel structures.