The main task of any operating heating system is to create the most comfortable microclimate in a suburban home. The correct organization of the heating system allows you to evenly distribute the heat fluxes over the entire heated area, as well as to protect the equipment units from possible overloads. The functional piping of a solid fuel boiler is the most important part of the procedure for connecting the unit to the heating circuit, carried out in accordance with the current technical standards.

- What is the harness for?

- Strapping options

- Features of piping single-circuit and 2-circuit boilers

- The principle of operation of a 2-circuit boiler

- The principle of operation and the device of a single-circuit strapping

- Advantages and disadvantages of a single-circuit boiler

- Strapping and circulation type

- Natural circulation of the coolant

- Forced circulation piping

- Collector system

What is the harness for?

A heating boiler belongs to a class of equipment, the use of which is justified only when a branched network of pipes with a coolant circulating in them (piping) is connected to it. From the point of view of the technical means used, the boiler piping includes the following components:

- steel, aluminum and combined radiators;

- valve valves that control them;

- coolant condition monitoring devices (pressure and temperature sensors);

- coarse filters;

- safety (buffer) valves and other auxiliary equipment.

This kit also includes an electric pump - an indispensable element of any dynamic system.

The piping of a heating boiler in a private house is necessary to ensure its functionality in accordance with its main purpose - effective heating of the surrounding residential spaces.

Strapping options

The choice of a piping scheme that is optimally suitable for a system of a given configuration directly depends on the specific version of the purchased boiler equipment sample. According to the method of placement within the premises chosen for it and the design of the liner, these units are divided into the following classes:

- typical floor standing boilers;

- lightweight (compact) wall devices.

The main requirement for the installation of units installed on the floor is to prohibit the insertion of their working nozzles into the upper section of the pipeline routing.

If this rule is violated, when piping a floor-standing boiler in systems that are not equipped with air valves, very dangerous formations (plugs) will appear. To reduce the likelihood of their appearance in the absence of valves, the pipe into which the boiler crashes should be located strictly vertically and have a special expansion tank in the upper part.

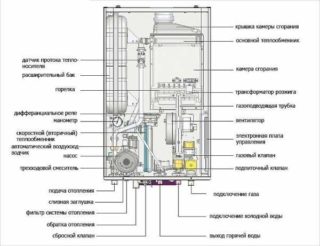

In the lower zone of units of all categories, automatic devices are provided to ensure their reliable connection to the heating main. Unlike the floor-mounted boiler, its wall-mounted counterparts already have an expansion mechanism that eliminates the formation of jams. When considering piping schemes for boiler rooms for such systems, it should be borne in mind that the advantage of wall-mounted models - low weight and not too large dimensions - are at the same time their disadvantage.This is due to the fact that compact units from DWG, for example, are limited in their energy capabilities. This means that the capacity declared by this manufacturer is sufficient for heating buildings with an area of no more than 100 square meters. Therefore, these devices are especially popular with city apartment owners.

A distinctive feature is the presence of two versions, differing in their configuration. The complete set of equipment includes most of the strapping elements, and the incomplete set lacks some units, which are purchased by the user independently.

If natural circulation heating systems are to be installed, some of the auxiliary equipment may not be required at all.

Features of piping single-circuit and 2-circuit boilers

The main difference between the existing methods of organizing the piping of heating systems is their energy capabilities. The power of single-circuit boilers, as a rule, is enough only to heat the structure - to heat the batteries. Such a unit does not allow heating water for domestic needs, which the consumer will have to take care of separately. 2-circuit boilers can not only heat the house, but also heat the water necessary for washing dishes or taking a shower.

The principle of operation of a 2-circuit boiler

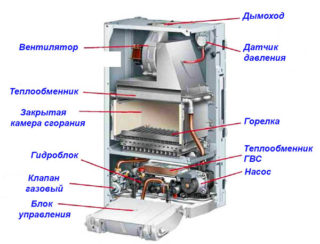

The design of these units provides for a special heat exchange unit (heat accumulator) designed for heating water and having two versions:

- flow-through products with the "domination of hot water supply" mode;

- units equipped with a built-in boiler.

If you need to take a shower or just wash the dishes, in the first case, it is enough to switch to this mode, after which the 2nd DHW circuit will be connected to the boiler. This performance is typical for units of domestic and foreign production. The piping of a double-circuit flow-type boiler is optimal for houses or city apartments of a not too large area (up to 75-86 sq. Meters), since not very powerful heat exchangers are built into these units.

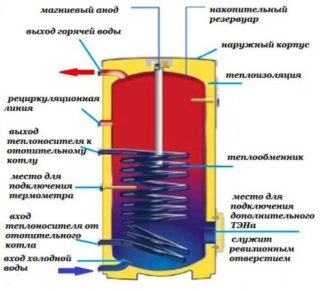

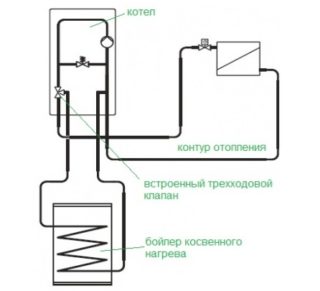

It is a completely different matter - boilers equipped with a storage boiler, whose tank capacity varies from 160 to 190 liters. They are intended for heating water both in storage and in flow mode.

Boiler models, even at the production stage, are equipped with a special heat exchanger, in which separately circulating water is heated by the energy of the heat carrier of the main heating circuit. For their normal operation, the manufacturer provides a special valve that controls the direction of movement of the energy carrier. The principle of domination of the DHW system is as follows:

- when the valve is in the closed position, the heat carrier, heated to a predetermined level, circulates through the heating system, heating the living space;

- if one of the residents opens the hot water tap, the boiler stops heating water for heating and continues to heat it in the boiler, while the second heating circuit is inactive;

- after the valve on the hot water pipeline closes, the system immediately directs the coolant to the batteries.

In two-pipe systems, both circuits never run at the same time. However, two-tube boilers are capable of providing multiple points of water intake. If a pair of drain taps is available, it is recommended to place the boiler approximately in the middle between them. If only one point is provided, it is installed as close to it as possible.

The principle of operation and the device of a single-circuit strapping

The liquid in the system circulates in a natural way, or a water pump is used for this purpose.

In most single-circuit models, it is possible to connect polypropylene pipes from the boiler to them. After that, the one-pipe system begins to operate in a 2-circuit mode, while observing the principle of priority.

Advantages and disadvantages of a single-circuit boiler

The one-pipe option of organizing the piping of TT boilers has the following advantages:

- relatively low cost;

- low costs for the purchase, installation and maintenance of the system;

- sufficient power for heating and high efficiency.

Most single-circuit models are available in floor-standing design, which allows the use of cast iron heat exchangers. Thanks to this, the efficiency of the heat carrier increases, which means that it is permissible to heat large areas (more than 100 sq.m.) with their help.

Systems with cast iron heat exchangers are often used in old type heating equipment (with gas boilers). In this case, a single-circuit piping of a gas boiler is preferable due to a decrease in the total consumption of the energy carrier. However, this statement is not always true. When arranging the piping of wall-mounted double-circuit gas boilers, supplemented by a boiler for domestic needs, fuel costs will increase.

Strapping and circulation type

The choice of the type of piping largely depends on the method of circulating warm liquid through the pipes and batteries of the loop system. There are two of them - natural movement and forced.

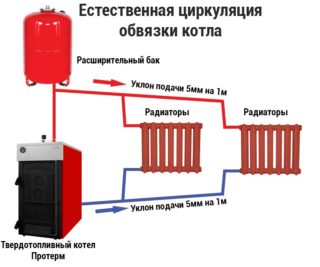

Natural circulation of the coolant

In the case of the circulation of the energy carrier, called natural, the piping of a solid fuel heating boiler in private houses provides for the mandatory use of a closed-type expansion tank. It is recommended to place it on the “return” at its lowest point and fill it with water by about 10% of the working volume. The structure of such a scheme includes the following elements:

- the heating boiler itself, operating on pellets, for example;

- inlet and outlet fittings;

- heating radiators;

- direct and return pipelines;

- a typical membrane-type expander.

The safety elements of natural circulation systems include a safety valve installed in them, which is connected to the drain hole by means of a rubber hose. Its main purpose is to relieve excess pressure when the coolant moves through the TT pipes of the boiler. In addition, it is customary to refer to them as special measuring instruments - manometers, with the help of which it is possible to visually assess the value of the pressure in the system.

Sometimes it is not necessary to install these elements separately, since they are already included in the boiler of the selected type.

The latter option is possible when purchasing wall-mounted models in the appropriate design.

Forced circulation piping

The operation of pumping equipment is accompanied by the installation in the heating circuit of a temperature sensor mounted in the return line.

The presence of an electric pump in the system allows flexible control of its operation, since it becomes possible to mount shut-off and control valves on radiators. Due to this, the coolant circulating under pressure easily overcomes the most remote and narrow sections of the polypropylene pipeline.

The use of a circulation pump turns the boiler into an electrical energy-dependent system. At the same time, the cost of heating also increases, since the costs of paying for electricity are added to the costs of maintaining an electric boiler.

Collector system

The collector piping of a solid fuel boiler includes approximately the same elements as conventional units. The only exception is the presence of a new component in it called the collector. Plumbers call it a comb, due to the similarity of this knot to a female comb. It is made in the form of an extended thick pipe, from which several thin branch pipes are diverted - one of them is inlet, and the rest are outlet. Through the first, hot water is supplied, which, when flowing through the system of pipes, is evenly distributed among the consumers. At the outlet of the copper collector, all these flows are re-collected and sent to the "return".