In country and private houses, stove heating equipment is still very popular. With its help, it is possible to heat buildings in areas where electricity and gas are not supplied. The foundation for the stove is the first thing that needs to be done before deciding on the arrangement of such a heating.

Types of bases

There are three types of foundation foundations that are used in the construction of brick stoves:

- solid concrete;

- rubble concrete;

- foundation foundation on piles.

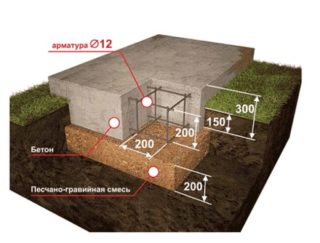

The classic foundation for a stove in a bathhouse is erected from rubble in combination with cement or entirely on the basis of concrete pouring. The base itself is made 50-100 mm larger than the dimensions of the stove, measured along the entire perimeter of the structure. In height, it should correspond to the same indicator for the house. Waterproofing (roofing felt or roofing felt) is laid on top of the finished base in two layers.

On top of the frame base, brickwork is being carried out, in which it is important to provide for special editions made on the basis of metal corners. These structural elements provide the so-called "fire separation". A feature of the pile foundation for the stove is the need to make several supports, which are equipped simultaneously with the preparation of the strapping for the whole house. A metal frame is then welded on their support sites, which serves as the basis for the future structure.

Pros and cons of each type of foundation

Stove foundations in wooden houses have a number of advantages related to each type separately. The advantages of a rubble base include:

- resistance to moisture, allowing it to be built in areas with a close location of groundwater;

- strength and reliability, which are based on the natural properties of natural stone;

- long service life (up to 50 years);

- attractive and aesthetic appearance.

Among the advantages of the bases for the stove in a natural stone bath, high environmental friendliness, frost resistance and resistance to temperature extremes are distinguished. But they also have certain disadvantages. Some of them:

- the need to select individual samples of natural stone, which significantly complicates the work and takes a lot of time;

- the admissibility of using only well-cleaned rubble, which in this case better binds to the concrete solution;

- laboriousness of laying due to the significant weight of stones and the need to work only by hand.

For the construction of the foundation, it will be necessary to prepare a trench up to 2 meters deep, which is associated with a large amount of earthwork.

The pile foundation for the sauna stove has the following advantages:

- high speed of installation;

- simplicity of arrangement, permissible even in winter;

- the presence of a ventilated base;

- quite affordable price.

The disadvantages of this option include the impossibility of deepening into rocky ground, as well as the difficulty of laying it in the vicinity of other buildings. It is customary to refer to the advantages of solid concrete foundations for a Russian stove:

- high strength indicators.

- guaranteed protection against subsidence.

- the relative ease of pouring a monolithic reinforced concrete slab.

The main disadvantage is the high level of material and labor costs.

Foundation laying calculations

In order to correctly calculate the characteristics of the future foundation, you will need to decide on its estimated dimensions. The latter depends on the weight of the sauna stove and its dimensions. When arranging a standard brick stove, a value of about 8 tons is taken for the average indicator of the mass of not dried masonry, after drying it decreases by about half. At the same time, the option is not excluded when the monolith expands over the area it occupies (for the chimney). This approach to the formation of the base avoids uneven shrinkage of the two components of the brick structure.

The depth of placement depends on the following factors:

- characteristics of the soil in a given area (its heaving, for example);

- the freezing point characteristic of these places;

- the indicator of the deepening of the foundation of the main building;

- depth of groundwater flow.

It is important to take into account the stage in which the construction of a residential building is at the time of the construction of the foundation for a brick stove. On sandy soils, it is laid at a depth of about 80 cm. When the variant of heaving unstable soils is calculated, the desired indicator is selected taking into account the freezing point of the soil.

Before starting the foundation arrangement, the approximate weight of the brickwork is calculated using the formula:P = 1350 x Vwhere V - volume of the structure in meters, 1350 - weight of 1 m2 in kg (mortar plus masonry of about 200 bricks).

Materials and tools

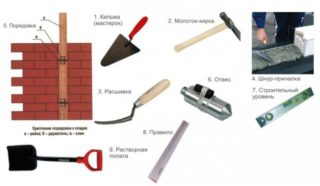

Before starting construction work, first of all, you will need to stock up on tools that are selected individually for each stage. For excavation and carpentry operations you will need:

- shovel-bayonet for preparation of the pit;

- shovel-scoop for mixing the solution;

- two sample sieve: for sifting cement and sand;

- a hammer.

It is necessary to prepare a metal trough or other container for the solution, as well as a tape measure, a pencil, a building level and a mounting stapler. From a set of building materials you need:

- boards going to the arrangement of the formwork;

- polyethylene for waterproofing;

- sand, dry cement and selected gravel.

To strengthen the foundation, you will need reinforcing mesh or iron bars.

Construction stages

The procedure for arranging a monolithic foundation for a stove in a bath does not differ from the general sequence of actions for the construction of a typical base. It includes the following steps:

- pit preparation;

- arrangement of formwork;

- pouring concrete mixture.

The construction works of various foundations differ in some details.

Under a brick oven

Step-by-step instructions for building a foundation for a brick oven:

- The trench is marked and the soil is selected to a depth of at least one meter.

- Crushed stone is poured into it, which is then carefully rammed.

- The bulk layer of the pillow is calculated for a thickness of 30 cm.

- A pre-prepared concrete mixture is poured.

The mortar is made in the classical proportion: 4 parts of sand are taken for one part of the cement, and then water is added to them in the required amount. At least a day is allotted for its setting, after which roofing material is laid on top (waterproofing). It will take about 2-3 weeks to solidify the finished base, during which the surface is periodically moistened.

Under a metal oven

A foundation for a metal stove in a bath is required only in cases where the weight of the structure exceeds 150 kg. Its use allows the oven to be installed strictly horizontally and to guarantee its constant position. The slightest deviations lead to deformation of structural elements and deterioration of its characteristics.

The order of operations for the construction of the foundation for the stove:

- Marking is made and a small trench is pulled out (no more than 0.5 meters deep).

- Crushed stone is poured in a thin layer, which is immediately compacted.

- A concrete mixture is poured in the same proportions.

Similar to the first case, waterproofing is done, the finishing layer of which is leveled.

Pile foundation

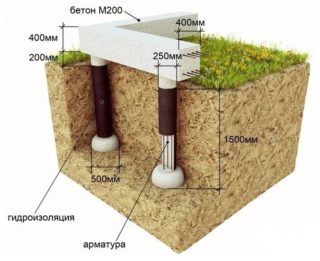

The procedure for arranging a support-pile foundation for brick ovens is somewhat different, since in this case a different technology is used. It consists in the construction of a series of pillars or pile supports, on which a frame is subsequently placed under the furnace structure.

Sequence of working steps:

- On the prepared site, markings are made corresponding to the dimensions of the furnace with an overlap of 10 cm on each side.

- With a bayonet shovel, about 20 cm of soil is removed, after which pegs are driven along the perimeter with a certain step, between which the string is pulled.

- At the intersection of individual threads, marks are made, along which holes are then drilled about 50 cm deep and 20 cm in diameter.

- Formwork is made from wooden planks in the shape of pits, and then installed in them.

- The bottom is closed with a 15 cm thick layer of sand, which is then carefully compacted.

Upon completion of these procedures, gravel is poured on top and filled with clean water, after which a reinforcing frame is knitted from a reinforcing wire with a diameter of 0.8 mm. Piles are installed in its center, the function of which is performed by asbestos pipes of appropriate length.

At the final stage of work, the entire structure placed in the pit is poured with concrete, the shrinkage and drying of which takes about 2 weeks. After that, they proceed to pouring the platform for the furnace, resting on the finished piles. It also takes about 2-3 weeks to dry.

The resulting foundation is very strong and reliable, but a lot of time and effort is spent on its arrangement. For those who wish to reduce the time of its preparation to a minimum, you can use the option of a concrete base.

Concrete foundation

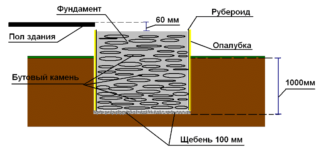

Step-by-step instructions for building a rubble foundation for a stove:

- A trench is marked for pouring the base, the size of which is chosen 10 cm larger than the dimensions of the furnace, taking into account a small margin for formwork.

- A pit is pulled out along the markings, at the bottom of which a pillow is made of selected rubble 15 cm thick.

- The formed layer is carefully rammed, after which several large rubble stones are placed on the very bottom (their diameter should not exceed 15 cm).

- Crushed stone is poured on top, filling the voids between the stones.

- A cement-sand mortar is poured into the trench to the depth of the layer, in the manufacture of which the classic ratio of 1 to 3 is used. For its preparation, cement of the M400 grade or higher is best suited.

After a day, another layer of stones is laid on top of the frozen mass, which are also filled with the same concrete composition. This procedure is repeated until the entire trench is filled with the rubble. After that, a building level is taken and with its help the resulting surface is checked for evenness. The detected irregularities are eliminated with the help of a liquid cement-sand composition. Then the base is covered with plastic wrap and left to dry completely (at least 2 weeks).

During the drying process, the surface is constantly moistened, and then covered again so that the sun's rays do not fall on it. At the end of this procedure, the formwork is removed and waterproofing is done, which is traditionally used as molten tar. The voids between the rubble base and the ground are filled with sand mixed with crushed stone.