The ideal conditions for living in a private house are considered to be normal humidity and the absence of temperature fluctuations. If one of these factors deviates from the optimal indicators, dampness appears in the premises of the first floor, walking on cold floors becomes unpleasant and hazardous to health. A comfortable microclimate is achieved through complex thermal insulation of the building. An integral part of this process is the insulation of the foundation and blind area. The correct choice of materials and adherence to the technology of their installation will allow you to achieve the desired result and extend the life of the building. This work is not particularly difficult, it can be easily done with your own hands.

The need to insulate the blind area

It is necessary to carry out insulation of the blind area for the following reasons:

- In cold winters, the soil freezes deep enough to completely cool the foundation and basement. The result of this phenomenon is increased heat losses and increased energy costs for high-quality heating of the building.

- A warm blind area retains well the heat that accumulates in the ground during the warm season. As a result, it takes much longer for the soil around the house to cool down, and the cold gets to its base.

- When freezing, heaving soil increases significantly in volume. This leads to the fact that already a few years after the construction of the walls of the basement and the strip foundation, they begin to be covered with cracks and squeezed out. As a result, emergencies arise that cannot always be eliminated even by major repairs.

- The insulated blind area in the winter keeps the heat, and in the summer cool in the underground part of the building. Thanks to this, the concrete remains stable. There is no chance of developing fungus and mold on it.

- Savings at the initial stage of construction. There is no need to make a deeply recessed foundation, since the layer of thermal insulation will reduce the level of soil freezing by 1.5-2 times.

The conclusion is obvious - it is necessary to insulate the blind area. It is advisable to do this even at the stage of building a building in order to initially exclude a negative impact on its foundation.

The choice of material for insulation

In many ways, the quality of insulation is determined by the characteristics of the facing coating. Most often it is made from asphalt, paving stones, concrete, paving slabs or artificial stone. It is advisable to choose materials that are distinguished by their tightness and insulating properties.

The following requirements are imposed on the insulation:

- lack of hydrophobicity, ability to resist moisture;

- biological inertness towards insects and microorganisms;

- resistance to alkalis and acids that are present in the soil;

- stability of volume and shape;

- long service life;

- strong enough to withstand earth pressure.

Not all materials have such characteristics.

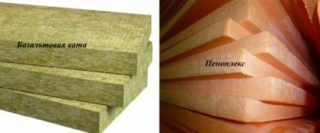

Extruded polystyrene foam

Extruded polystyrene foam (penoplex) is made on an extruder through which a foamed polymer mixture is passed under pressure. Finished products are slabs of various shapes and thicknesses. A distinctive feature of the product is the edge in the form of a step. This solution results in a seamless surface with excellent insulating properties.

In addition, the material has the following advantages:

- waterproofness;

- elasticity and slight flexibility;

- low density;

- low thermal conductivity;

- resistance to a chemically active environment;

- ease;

- simplicity and high speed of installation;

- immunity to temperature changes;

- long service life of at least 50 years;

- environmental Safety.

Insulation of the foundation and blind area of the house outside with expanded polystyrene can be performed in any type of soil, including excessively wet.

Penoizol

Penoizol is an effective product that can be applied to even and difficult surfaces. The liquid under pressure adheres tightly to all substances, after foaming, it fills all the voids. The result is a monolithic layer of dense substance with a penoplex-like consistency.

Penoizol advantages:

- biological resistance;

- the highest application speed among analogs;

- excellent adhesion to any materials;

- resistance to temperature changes;

- does not decompose;

- no need for preparatory and finishing work.

The disadvantage of the material is its price. Insulation is carried out with household aerosol cans or using industrial equipment. Both are quite expensive.

Styrofoam

Polyfoam is a proven insulation material that has found wide application in private construction. One of its advantages is the price affordable for all categories of the population, which allows the use of expanded polystyrene on a large scale. It is produced in the form of square meter slabs with a thickness of 50 mm, 100 mm, 150 mm and 200 mm.

In addition, the material has the following advantages:

- ease;

- low thermal conductivity;

- ease of installation;

- durability;

- water resistance;

- ecological cleanliness.

The disadvantage of foam is its fragility. Plates crumble and break from impact and pressure. When working with them, you need to be careful and careful.

Expanded clay

Expanded clay is the result of vulcanization of a substance based on natural clay. The finished product is round porous balls. It goes on sale in bulk or packaged in bags. The material has an affordable cost, which makes it popular with private developers.

The insulation has the following advantages:

- Ease of use;

- low thermal conductivity;

- environmental Safety;

- biological inertness.

Expanded clay also has disadvantages. Over time, the granules decrease in size, leading to the formation of voids. In addition, expanded clay is highly hygroscopic, absorbs water well, as a result of which its operational characteristics deteriorate.

Step-by-step instructions for insulating the blind area

The arrangement of the base of the house should be carried out in the warm season, when the earth has dried well and settled after the winter heaving. You should check the weather forecast for the week, as it will take several days to work. It is inconvenient to perform it through mud, and precipitation will adversely affect the quality of the masonry.

Step-by-step instructions for insulating the blind area around the house:

- If the house was built a long time ago, dig a pit around it with the design parameters of width and depth.Remove stones from it, if trees grow near the house, chop off and burn the roots to prevent their further growth.

- Insulate the basement and basement from the outside. First, concrete must be cleaned of dirt and dust, then treated with an antiseptic and strengthening impregnation. After that, you need to cover the base with a layer of waterproofing. For this, mastics or molten bitumen are used. In conclusion, insulation is applied. Foam, extruded polystyrene foam or foam plates are used. Since the material will be underground, additional processing is not required.

- Fastening a waterproofing film to the wall of the trench. It is better to use dense cellophane. The width must be taken such as to ensure a bend from the bottom and top by 30-40 cm. This technique will prevent the lateral flow of moisture into the insulation when the soil is very wet.

- Laying a soft profiled membrane. Better to use the brand Planter produced by TechnoNIKOL. The fabric is strong and durable. The membrane will provide moisture drainage and prevent plant germination.

- Manufacturing of an amortization cushion. It is made of crushed stone and sand, which are alternately poured in layers at least 30 cm thick. The sand is compacted and leveled. It must first be moistened and then processed with a manual or mechanical rammer.

- Applying a layer of insulation. It is advisable to take plates of 10 cm foam or 5 cm foam. If foam is chosen, it is applied in 3 layers, each of 3 cm. Spraying the next level is carried out only after the previous one has solidified. Expanded clay is filled up, leveled, but not pressed down.

- The cracks in the slabs are blown out with foam, membrane fabric is laid on top of the expanded clay.

- If concrete is selected for the top layer, a removable plank formwork is made. Wooden crossbars are installed every 200 cm for thermal expansion of the blind area.

- A reinforcing cage is being made. Plastic or stone supports 2-3 cm high are placed under it.

- A damper tape is glued around the perimeter of the basement level. It will ensure the tightness of the joint.

- Mixing and pouring of concrete is carried out. To achieve the required strength, a layer of at least 10 cm is made. A slope of 2-3º is attached to the blind area.

The finished structure can be used after 14 days. To give the concrete a presentable look, it is painted or polished.

How to avoid mistakes when insulating

To do the job efficiently the first time, the following rules must be followed:

- Before starting work, carefully think over the arrangement of the underground pie. Not a single trifle should be overlooked, otherwise the effectiveness of the design will be insufficient.

- When composing a scheme for insulating the blind area with penoplex, the plates should be staggered so that the coating works better.

- Choose durable materials that are resistant to moisture and pressure. You cannot save on installation.

- Make a blind area of maximum width and depth. This helps to reduce heat loss and better insulate the base of the house from the effects of cold, especially in severe winters.

Subject to the construction technology, a high-quality result will be guaranteed, the building will receive an additional service resource.

Tools and materials for work

Arrangement of the blind area should start with drawing up a project. It is necessary to correctly determine the width and depth of the structure. For clay soils, you need 1 / 0.5 meter, respectively, and for sandy soils - 1.5 / 1 meter. Then you need to select the materials that are most suitable for the specific construction conditions.

To work, you will need the following tools:

- concrete mixer;

- building level;

- roulette;

- shovel;

- saw on wood;

- a hammer;

- ax;

- marker;

- scissors;

- household stapler;

- notched trowel;

- stationery knife;

- paint brush.

Depending on the project, the list can be extended or shortened.

An indicative list of building materials:

- insulation;

- sand;

- cement;

- crushed stone;

- membrane film;

- cellophane;

- boards 200 mm;

- primer;

- nails.

To protect the skin, eyes and breathing, you need to work with gloves, goggles and a respirator. Having everything you need, you can easily make a warm blind area, spending 2-3 days on this event.