For the arrangement of the underfloor heating system, a suitable adhesive is required. The selected product must have high strength and elasticity, retain its properties at temperature extremes. Therefore, among a large assortment, you need a suitable mixture, having studied in detail its qualities and performance characteristics.

Types of warm floors

The installation procedure for different heated systems may differ. Therefore, you need to pay more attention to which surface the tile adhesive for underfloor heating will be applied.

Electrical

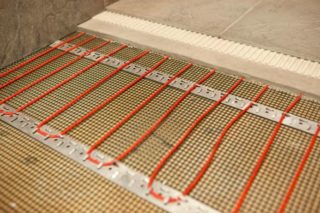

Such floors are divided into film and cable. Tiles are not used for film floors, as the structure cannot be repaired, which makes it unprofitable. If a cable underfloor heating is installed, mats are used that have the form of a cable laid on the footboard with a mesh, or a cable element laid out with a snake. It is secured with tapes.

Most manufacturers recommend laying the floor with an adhesive or in a screed. If an adhesive was chosen, you need to find out what will be the basis for the cable:

- cement or concrete;

- wood base, such as plywood or chipboard;

- synthetic base;

- bitumen or polymer.

Only on such materials can the cable be laid using tile adhesive for underfloor heating.

Aquatic

This structure consists of pipes and mats. Pipes are laid on mats that have a figured or solid appearance. When the mats are solid, a mesh of reinforcement is used, on which the heating elements are placed.

From above, this system is poured with a screed, its thickness should be 3-7 cm. A solution is selected that is suitable for the base in the form of concrete.

When the water floor is installed on a wooden layer, the pipes are mounted in special recesses, which are in the form of a plate with a heat-reflecting effect. These plates, in turn, are placed in the grooves in the floor. Plywood with increased moisture resistance should be used, its thickness should be 1 cm.

If plywood flooring is used, a mixture that is suitable for the wood is needed, it is more elastic.

Infrared

This floor is placed under laminate or linoleum. Infrared rays affect all objects that are inside the room, warming them. The air in the room is also warmed up.

There are two types of infrared flooring:

- rod;

- film.

The core floor consists of carbon elements, the length of which reaches 80 cm. During installation, they are poured with concrete screed, in a layer of 2-3 cm. After that, the tiles are laid, a mortar suitable for concrete is used.

The film floor can be carbon or carbon. Both types are 0.4 mm thick film. This allows you to mount it directly on the screed. A composition for linoleum is used.

Classification of glue by composition

The adhesives contain different components. Therefore, before choosing, you should find out about its varieties.

One-component

The mixture is convenient to use, because it is supplied ready-to-use in special buckets.The composition of such adhesives includes resins, acrylics, modifiers. The mixture hardens after 20 minutes, which makes it possible to correct the laid tiles.

Two-component

Mixed from two components before starting work. Created on the basis of epoxy resin and polyurethane parts. The adhesive is able to withstand temperature extremes, has significant elasticity and adhesion properties. It hardens quickly, adheres to any surface.

Universal

This type of glue is created on a Portland cement base with the addition of sand and plasticizers. It is the most popular of all types of adhesive solutions. Sold dry, prepared in warm water before starting installation work. The proportions are indicated on the packaging.

Specifications

Solutions have certain characteristics, thanks to which you can choose an adhesive for any surface. The characteristics are as follows:

- anti-slip - the mixture holds the material firmly on the floor;

- the retention time of the characteristics - usually from 1 to 3 hours, during which the composition does not change its properties;

- working life - for a simple glue, it is in the range from 10 to 30 minutes, a quick-drying solution - from 5 to 10 minutes;

- correction time - on average, this interval is 20 minutes, during which you can correct the position of the tile.

These properties will allow you to select the glue for a specific surface and will help to adjust the time allotted for installation.

Technology of use

Preparation of the base

Before starting, you need to prepare the base. This is done according to the instructions:

- dust, debris and other objects are removed from the floor and screed, you can vacuum;

- the surface is primed, this will improve the adhesion of the glue;

- the surface is finally dried.

After the operation has been completed, you can start creating an adhesive solution.

Features of the preparation of glue

To prepare the mixture, you need to do the following:

- the proportions will be indicated on the package, you must follow them;

- after mixing the ingredients, add water;

- the composition is applied to the screed and leveled with a spatula.

It is recommended to spread the mixture gradually in order to have time to lay the top layer of the floor.

Features of laying tiles

The tiles are prepared in the following way:

- to increase adhesion, you can prime the tiles from the inside;

- the mixture is applied to the material, the thickness of the solution is minimal - up to 0.5 cm;

- the tile is laid, equal gaps should remain between its parts, plastic crosses can be used, which are removed after 2 hours.

After the substance has completely dried, grouting is carried out.

Adhesive selection criteria

For laying a warm floor, you need to choose a composition that has the following characteristics:

- resistant to temperature extremes, capable of transferring the range from -30 to +90 degrees without loss of quality;

- the level of the coupling must be at least 0.8 MPa;

- must be compatible with many surfaces, this is indicated on the packaging;

- ease of use - ready-made components in a package;

- acceptable price;

- the composition must include components that will make it resistant to loads and influences.

If you have any doubts when choosing an adhesive for porcelain stoneware or other material for a warm floor, you should consult a specialist.

Popular manufacturers rating

Glue Ceresite for underfloor heating has a high degree of elasticity, can be used for various coatings, the service life extends for many years. It is also environmentally friendly and safe for human health. Can withstand extreme temperature changes. It is important to follow the requirements stated on the packaging.

Solution Bergauf for porcelain stoneware, it dries quickly on a warm floor, you can walk on it 4 hours after the end of work.You can change the position of the tiles within 10 minutes after application. Withstands temperature drops from -10 to 70 degrees. Recommended for people who have experience in such work.

Glue Knauf used for laying on a complex base, such as a gypsum fiber coating. The mortar has a high degree of elasticity and adhesion, increased waterproofing. It is possible to correct the laid tiles within a few minutes after application. Withstands temperature drops from -30 to 80 degrees.