A double-circuit gas boiler is used for autonomous heat supply. It is convenient in that it can serve two engineering networks at once - heating and hot water supply. When using such a device, there is no need to purchase a water heater. It is convenient to use a water heater in summer, when space heating is not needed. This is possible due to the summer mode, in which all the heat is spent on water. Before buying a boiler, you should familiarize yourself with its device, principle of operation and operating modes.

Device design

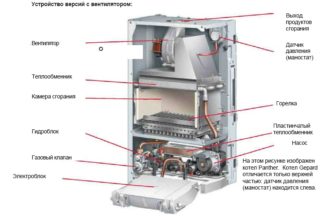

In the circuit of the device, regardless of its type, there are the following details:

- Burner. It is installed in the combustion chamber. It is the main working part of the heating structure. The main task is to heat the coolant and generate heat for the operation of the water heating circuit. To maintain the exact temperature, it is equipped with an electronic flame modulation system.

- The combustion chamber. It happens open and closed. It is a housing for the burner. The closed chamber contains a fan that accelerates the air and removes the combustion products. Gives little noise during operation.

- Circular pump. Provides circulation of the heat carrier through the heating system and the water heater circuit. Works silently.

- Three-way valve. Responsible for switching the heating circuit to water supply and vice versa. Directly depends on the water tap.

- Main heat exchanger. In this part, the heating medium is heated. Installed above the burner in the storage room.

- Secondary heat exchanger. Responsible for preparing hot water.

- Instrument automation system. The sensors installed in the heater monitor the parameters of the equipment, are responsible for safety, activate various units, detect and correct errors, and perform a number of other useful functions.

Water is supplied through a special tube at the bottom of the housing. It is also discharged through a branch pipe that connects to a tap. It is important to note that the heat exchanger does not mix with water during operation.

Some units have a twin heat exchanger. The principle of its operation remains the same, although the design is slightly different.

Operating principle

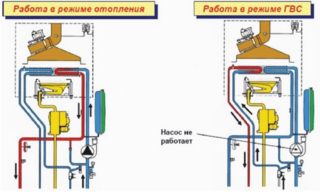

Heating operation

In this mode, the boiler acts as a heater. Simultaneous work on heating the room and water is not possible.

As a heating device, the boiler works on the same principle as a conventional instantaneous heater. First, the device turns on and warms up to the declared temperature. When the limit is reached, the gas supply stops. If the boiler is equipped with a temperature sensor, the automation will take these readings into account.

The operation of the burner is also influenced by the automation that measures the temperature of the outside air. The sensors allow using the boiler only in cold weather. This significantly saves energy.

A working gas burner generates heat. It heats the coolant, which then circulates through the heating system, heating the room. During operation, combustion products are formed, which are removed in two ways - with the help of a fan or independently. Water heating is off. A three-way valve is responsible for this.

Water heating operation

The water circuit is activated when the user turns the water tap. When the water flow is applied, a three-way switch is activated and the heating system is turned on. At the same time, the gas burner is ignited, after which warm water begins to flow from the tap. When the boiler is switched to hot water supply, the heating circuit is switched off.

After turning off the tap, the three-way valve is reset and the secondary heat exchanger is cut off. All energy is directed to the heating system.

Heating the room is required only in the cold season, as opposed to heating the water, which is needed all the time. In this case, the boiler is switched to summer operation. It is activated by pressing the corresponding button on the device body. The three-way valve cuts off the heating line and the coolant is circulated in a closed loop inside the boiler.

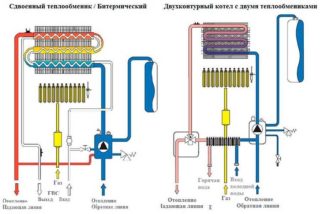

Boiler with bithermic heat exchanger

A coolant circulates along the outer part of the tube, which enters the heating system. Water appears in the inside after opening the tap. When the user turns the tap in the sink, the heating circuit is shut off and all the energy is spent on heating the water. The circulation pump is inactive during this time.

When hot water supply is interrupted, the pump is activated and the heat carrier enters the heating circuit. Bithermic heat exchanger models require fewer sensors and automation. As a result, the cost of such products is higher, and the efficiency in water heating mode is higher and reaches 93.4%.

The disadvantages include the risk of pipe clogging. It manifests itself in the event of leakage and poor sealing of the pipes. In this case, it is rather difficult to clean the heat exchanger; the help of a specialist may be required.

Heat exchanger selection

When buying a double-circuit gas boiler, it is important to decide in advance what type of heat exchanger is needed. The main criteria by which you can make the right choice:

- Is there a need for fast water heating. If yes, preference should be given to models with a bithermal heat exchanger. The liquid will be heated directly from the burner, so less gas and electricity are required. In this case, the temperature will be maintained more accurately.

- Devices with separate heat exchangers are practically not clogged. Failed pipes can be replaced. In the event of a breakdown in the bithermal device, both circuits will not work. It is more difficult to flush such a heat exchanger.

- The capacity of devices with a separate heat exchanger is higher, since the pipe is not divided into sections. The device, arranged in a double way, passes less heat carrier.

- Climatic conditions must be taken into account. When operating in summer mode, it is more profitable to buy a bithermal heat exchanger.

- The cost of a bithermic heat exchanger is higher than that of a separate one.

A bithermal heat exchanger is more difficult to operate, but it has smaller dimensions.

Advantages and disadvantages

The positive qualities of a double-circuit gas boiler include:

- Economical fuel consumption.Automation makes the use of such models even more profitable, as it disconnects and reconnects as needed. Working in the summer also saves fuel and money.

- Compactness. The loop boiler can be placed in a small utility room or in a small kitchen. Floor-standing models are slightly larger than wall-mounted ones.

- Versatility. There is no need to purchase additional parts and a boiler.

- Combining a water heater, a heating device and a circulation pump in one housing.

Of the minuses, one can single out the impossibility of simultaneous heating of water and heating and the limitation on the power of wall-mounted appliances. The heat exchanger is also sensitive to water quality. The principle of operation of a double-circuit boiler is more complicated than a single-circuit boiler, but at the cost of the first one it is more profitable to buy.

There are a number of points that you need to pay attention to in order to choose a double-circuit gas boiler: principle of operation, circuit, power, type of heat exchanger, manufacturer. Preference should be given to models from well-known companies.

Many well-known brands are engaged in the production of water heating and heating devices, including Bosch, Ariston, Visman, Navien. Leading places in the ratings are occupied by Buderus Logamax U072-24K, Lemax PRIME-V32, Navien DELUXE kotel 24K. All products are of high build quality, good performance, and a warranty.