Any heating system requires the correct choice of wiring diagram. This will help organize a more efficient coolant supply with minimal power loss. For those who want to preserve the aesthetic appearance of the room, without disturbing the harmony of its interior, and to facilitate installation, it is recommended to choose a heating radiator with a lower connection, which is almost always equipped with a built-in thermostat. Batteries of this type are panel and steel with 1-3 heating panels.

What heating systems is used

The bottom connection of heating radiators is used for the following CO:

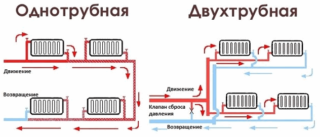

- One-pipe lines. In this case, a bypass wiring is organized, which helps to prevent uneven heating of the radiator circuit, where the nearby ones warm up to the maximum, and the subsequent ones do not receive the necessary heat supply.

- Two-pipe lines. For this option, binoculars are used with shut-off or control valves. The radiators warm up evenly, so temperature compensation is not required.

- Combined node. It is provided with an internal bypass channel and is mounted in both one- and two-pipe systems.

An air vent must be installed on each radiator. When choosing the bottom connection, it is necessary to provide for the factor that the heat loss increases by an average of 15%.

Advantages and disadvantages

Heating radiators with a bottom connection have the following advantages:

- saving materials, only two short leads are needed to dock the radiator;

- aesthetics and harmonious combination with any interior, the pipeline coming out of the wall is practically invisible, and the structure does not interfere with cleaning the floor;

- uniform distribution of the coolant throughout the battery due to the use of a vertical bypass and the ability to control the intensity of water intake due to shut-off and control valves;

- ease of implementation of any design solution;

- providing unhindered access to control elements and bushings;

- fast heating of the bottom.

In addition to the advantages, radiators with bottom connection have some disadvantages:

- not suitable for gravity heating;

- an air diverter valve is mandatory;

- for continuous circulation of liquid, a booster pump is required;

- uneven heating of parts of the registers;

- to eliminate defects on pipes, it will be necessary to dismantle the floors and violate the integrity of the finish;

- dependence on the availability of energy supply.

Before choosing the bottom connection of radiators, it is worth evaluating all the pros and cons and only after that proceed with the installation.

What radiators are used

For the bottom connection, there are some requirements that radiators must meet, since in this case the coolant is distributed over a continuous zone and the usual sectional structures will not work here.

Panel

Manufactured from aluminum alloys. Special U-shaped fins increase the heating area and heat transfer. The front side is made in the form of a solid panel. The main advantages of such a battery include: light weight, attractive external characteristics, energy saving, low price, wide range of models, durability.

For social institutions: hospitals, schools, kindergartens, special options are available with a smoother surface that facilitate regular care.

Profiled steel

Panels of rectangular shape, simple in design, can be of different sizes. The battery consists of several plates connected by welding, inside of which there are vertical elongated channels designed for the circulation of hot liquid. U-shaped steel fins are used to increase heat transfer.

Such a battery has a number of advantages: long service life, more than 25 years, compatibility with most types of boilers, there are no strict restrictions on the choice of heat carrier, aesthetics, ease of installation.

Since radiators made of profiled steel are prone to quick contamination, it is recommended to install dirt filters in parallel during installation.

When purchasing a structure, it is important to take seriously the quality of the coating, which should protect the selected specimen well from corrosion and maintain its original characteristics for many years of operation under intense thermal exposure, where the maximum temperature reaches 130 ° C.

Consumables for bottom liner

- fitting;

- set of adapters;

- packaging means;

- solder sleeves;

- thermostatic, control valves;

- threaded "American";

- shut-off valves, installed at the inlet, outlet, ball valves allow you to shut off the flow of the coolant into the radiator and regulate the rate of fluid intake;

- plug, designed for the fourth entrance in the battery, painted white and does not spoil the overall appearance of the structure;

- tow or sealing paste;

- Mayevsky's faucet is an air outlet, most often supplied complete with adapters.

The list depends on the type of radiator selected. Fastening materials are also used in the form of hooks, brackets, floor installations.

Installation features

There are three bottom connection methods:

- using conventional batteries with bottom holes;

- the use of special radiators with a characteristic design;

- by means of the accessory kit at the bottom of the selected model.

Installation can be done in different ways.

With lateral outlets

The pipes are placed underneath the flooring or above the floor. The radiator is mounted on the wall and piped to it. To facilitate the dismantling process, shut-off valves are installed on each side.

With adapter

If it is not possible to bring the pipeline to the battery from both sides, an adapter is used, which is inserted into the hole from below, and a tube with anti-corrosion properties is passed from above.

With flow extension

This type of installation is not compatible with gravity systems. The flow extension is mounted in the lower hole of the heating product. In this case, there are no bends to the top of the model.

The most optimal bottom connection is installation from the bottom, for this a specialized radiator is purchased, which is already provided with a thermostat, two nozzles with the desired direction and the possibility of inserting a flow direction adapter.

With any connection method, the battery should be located 10 cm from the floor, windowsill and 5 cm from the wall.Depending on the layout, the pipeline is laid under the floor, in the wall, between the flooring and the radiator. The chosen installation method does not affect the heating efficiency.