The rejection of the standard one-pipe or two-pipe wiring in favor of a manifold distributor or manifold makes it possible to save fuel and create a comfortable environment in all rooms. The heating comb is an important component of the heating system; this part is divided into several types depending on the material, the level of complexity and the number of connection points. When choosing an element, you need to take into account the basic criteria and study the installation rules in advance.

Classification of combs for heating

The heating comb is selected according to specific criteria. All devices of this type are divided into several groups. This includes selection according to the number of branches, material of manufacture and the degree of complexity, taking into account the installation in a heating home system.

By material

Elements made of polypropylene are considered inexpensive and economical. They have a high level of reliability and can be used with heat carriers of any quality. These options should not be installed in systems operating under conditions of high pressure and high temperatures.

Elements made of steel are more durable, they are divided into two categories: options from stainless alloys and ferrous metal, which is coated with a layer of chrome or nickel. They have a long service life and are designed to last a long time. Non-ferrous metal parts are rust resistant, reliable and durable. A bronze or brass comb for a warm floor or heating system is capable of operating at any pressure or temperature.

By difficulty level

By type of scheme, design features and size, parts can be simple or complex. Simple elements distribute the flows of the heat carrier to the required number of nodes, due to which heat enters each room. They consist of a branch pipe, connections on both sides, and two to four branches. Their main disadvantage is the inability to control streaming coolant jets.

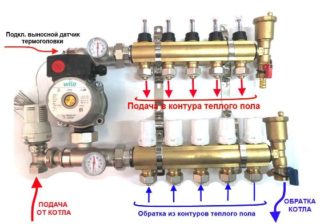

The complicated distribution manifold of the heating system has advanced functionality and many details. Their list includes pipeline fittings, an automatic system, sensors for monitoring or accounting for all variants of the heating system. In parts of this type, you can independently supply and regulate the level, consumption, supply and pressure of the heat carrier.

Collector elements are also categorized according to the number of branches. They can be double, triple or quadruple, depending on the number of connection points. It is necessary to choose the appropriate option for this parameter, taking into account the design features of a particular heating system.

The purpose of the comb

A collector or comb for plastic pipes and analogues made of other materials is a tube with a plug in the end part and a pair of branch-shaped branches that direct the heat carrier to separate points. The collector is designed to optimize the flow of the heat carrier within the heating circuit and smooth out water hammer arising from the operation of the boiler automation, which is responsible for temperature control.

The element is needed to create underfloor heating systems, and is also used in radiator-type heating systems. The collectors are connected according to the beam scheme, each has its own supply and return pipe, with its help the heat carrier is returned to the collector. Due to this heat distribution, the radiators are heated evenly, which makes it possible to regulate the temperature in all rooms or completely turn off the heating in a separate room.

Using a comb, you can connect additional devices, for example, a pool in a separate house, which requires water heating. It can also be auxiliary energy sources, for example, solar panels.

Placement rules and methods for installing the collector

The comb for the heating system and underfloor heating should be stored in a manifold cabinet or a special niche, but such equipment is not required. Often, additional elements are installed on equipment of this type, including flow meters, valves, thermal heads and much more. They are designed to regulate the flows of the heat carrier and their direction into a separate device.

The comb for standard or metal-plastic pipes is supplemented with taps, with which you can disconnect the manifold. In addition to them, automatic air vents are mounted on the collectors.

The collector must be connected to the riser and pipes drawn from it to the plumbing elements. In a standard heating manifold, two elements are placed each for the supply and return of fuel. During installation, it is important to maintain equal distances between the collector and the heating device. Otherwise, on the longest sections of the system, the pressure will begin to exceed the norm. Each next segment should be half the size of the previous one.

In the closet

For any floor or wall-mounted collector, you can equip a separate cabinet or niche, which are located in the wall at a low height above the floor. It is allowed to connect the element only in a dry corridor or storage room. Experts recommend making cabinets from sheet metal with technical holes and a door. In such boxes, they equip additional fasteners for the collectors, the cabinets themselves can be made by hand or contact the master.

On the wall

Collector elements placed in the closet of the apartment can be hung on the wall using brackets. This saves time and money on cabinet manufacturing. Mounts must be selected taking into account the size of the comb.

Installation rules

The comb is fixed on the wall using brackets, then the main pipes are attached to the end and proceed to the strapping stage.

The comb can be mounted in two ways: without a hydraulic arrow or with pressure equalization. In the first case, a home-made or purchased collector will serve several contour elements, where the temperature of the coolant will not be adjusted and will remain at the same level. Each circuit is connected directly to the element and one pump is connected to it for circulation. All parameters of the equipment must correspond to the performance of the heating system and the pressure of the heat carrier.

The pressure equalization method is needed when it is necessary to provide a different temperature at all points of consumption. For example, in batteries, it should be kept within 50-80 degrees, in systems for underfloor heating from 40 to 50 degrees.

The water gun is a piece of pipe that is sealed on both sides and supplemented with several nozzles. The first pair is needed to connect the hydraulic arrow to the boiler equipment, the second is required to connect the combs. It is a convenient barrier that creates an area for low flow resistance and fluid collection.

Criterias of choice

The element model must be selected at the design stage. The number of terminals for the collector must correspond to the number of circuits. Due to the length of the routes and the pressure within the network, pumps are not used to force the flow of liquid. In private buildings, where more than 100 meters are laid, additional traction must be created for the pipes within the system. When installing underfloor heating, pressure drops also often occur.

A properly sized comb must balance the performance. During the selection, first of all, they look at the pressure indicators, as well as the temperature. Such an element can be of a simple or complex type, the second option is suitable for those who need a comb with auxiliary options. Innovative elements help you to set and control temperatures and other indicators.

Thermal sensor options help determine which rooms heat exchanges faster, where water provides less energy. Proper adjustment will prevent fluid from flowing where it is not needed.

When choosing, always take into account the material from which the comb is made. It can be cast iron, steel, brass or plastic. The ideal option would be cast elements that exclude any leaks.