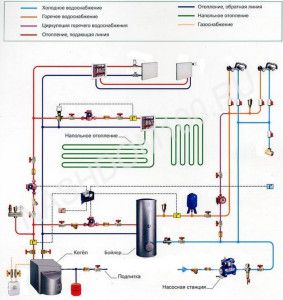

What parameters should be given special attention when choosing components for heating? These include performance specifications that must match the design data of the system. However, in addition to this, the correct piping of the heating system is needed: boilers, pipes, radiators, pumps. She should be given special attention.

Appointment of piping heating equipment

Why do you need a piping diagram for a heating boiler, radiators and pipes? Its primary task is to ensure the correct operation of a specific heat supply element. Since the parameters of the system are not stable, their timely adjustment in a specific area is necessary.

Correct piping of a heating boiler with your own hands begins with the selection of its components and their adaptation to the parameters of heat supply. They can be installed both in the immediate vicinity of the strapping object, and remotely. It is important that their work does not affect the current qualities of this element of the heating system.

Regardless of whether the piping of the heating pump, radiator or boiler is planned, a number of conditions must be met:

- Determination of the optimal circuit and its components. It depends on the purpose of the heater and its required functionality after starting the heating system;

- The degree of influence on the radiator or boiler of the piping components, the possibility of automatic or manual adjustment of their operation;

- Ensuring optimal operation of the entire heating system - limiting the flow of the coolant at a specific section of the pipeline, mixing it with chilled water to reduce the current costs of the energy carrier;

- Work safety. It is for this that the piping of a double-circuit heating boiler is intended.

In addition, you need to take into account the material of manufacture, the possibility of creating reliable attachment points and the compatibility of the strapping components with each other. As a result, the developed scheme should ensure the normal operation of the entire heat supply system.

The piping of a floor heating boiler, radiators or pumps depends on the temperature regime of the system. All components must be rated for the highest possible heating.

Boiler configuration

In almost every video of the heating boiler piping, special attention is paid to the piping layout and the general organization of heating. It is on these factors that the required functionality of the boiler depends, as well as the safety of its operation.

At the first stage, it is necessary to decide on the boiler model, the type of fuel used and the design. They will determine which piping of a diesel heating boiler will be optimal for a particular scheme. In addition, you need to take into account the following parameters of heat supply:

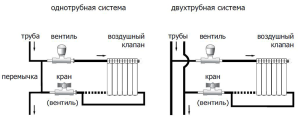

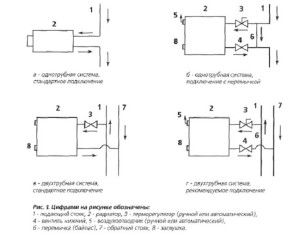

- System type - one-pipe, two-pipe or collector. The method of connecting the boiler depends on this, as well as the list of additional components for its operation;

- Equipment... The correct piping of an electric heating boiler may include a protective bypass and shut-off valves. If the device does not include a circulation pump, an expansion tank and a safety group, these elements must be installed for hot water heating;

- Pipeline material... So, the correct piping of a heating boiler with polypropylene may differ depending on its design - solid fuel, gas or diesel. In some cases, the primary pipe is necessarily made of metal.

In practice, you can simplify the solution to this problem by reading the instructions from the manufacturer of a specific boiler model. It provides a complete list of materials, shows a piping diagram for an electric heating boiler or its solid fuel analogue. But besides this, there are general recommendations for additional equipment for heating the house, depending on the type of boiler.

Before purchasing a boiler, you need to familiarize yourself not only with its functionality, but also with the complete set. She will determine the optimal piping scheme for the heater.

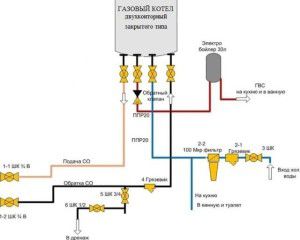

Gas boiler piping

This is the most common type of heating equipment for heating the coolant. There are many models that differ not only in appearance, but also in functional features and equipment.

For piping a double-circuit heating boiler, in fact, it is required to adapt it to the operating conditions of a certain heat supply scheme. If the equipment of the device already includes a safety group, a circulation pump, an expansion tank, you will additionally need to install the following components:

- Shut-off valves - mounted on all branch pipes. It is best to use ball valves in the heating boiler piping scheme, since they can be used to quickly shut off the coolant flow;

- Thermometers and manometers... If the boiler is not equipped with these measuring devices, installation on the supply and return pipes is mandatory. If available, you can limit yourself to strapping the heating boiler with your own hands by mounting a thermometer and a pressure gauge on the return pipe;

- Mixing unit... It is necessary to optimize the flow rate of the heating agent. If, according to the readings of the temperature sensors, the degree of cooling of the return flow of the coolant is low, it can be mixed with hot water.

When tying a heating boiler with polypropylene, you should do without installing transitional corrugated hoses. This is a prerequisite for the installation of wall-mounted double-circuit models.

Some sources recommend the organization of a small auxiliary circuit for preheating the water. After that, it supposedly should be submitted to the main one. This should not be done, since a large temperature difference can lead to thermal shock, which will cause failure of pipes, radiators and even a boiler.

For better DHW operation, it is recommended to install an auxiliary storage tank. Its capacity can be from 50 to 200 liters.

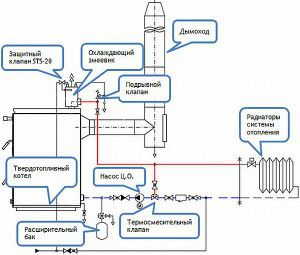

Components for solid fuel and diesel boilers

For piping a diesel heating boiler or its solid fuel analogue, one should take into account the high inertia of this type of equipment. Those. the rate of temperature change is much lower than that of gas models. This is especially true for solid fuel boilers.

Analyzing the video of the heating boiler piping, we can conclude that special attention is paid to the safety group. This is due to the above-described factor for adjusting the intensity of fuel combustion. Therefore, in addition to installing the elements necessary for piping a floor-standing gas-type heating boiler, the following components must be installed:

- Air vent... With its help, the accumulated air arising as a result of overheating of the coolant is given;

- Drain valve... Each piping of a floor heating boiler is equipped with it. It performs the same functions as the air vent, but for the coolant - water. As a result of overheating, it expands, which leads to an increase in pressure.To stabilize the system, it is necessary to forcibly remove some of the liquid, which the drain valve successfully copes with.

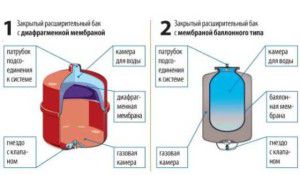

In addition to these components, an expansion tank must be present in the boiler piping diagram. Its design and installation location depends on the type of system - open or closed.

In open heating, the expansion tank is installed at the highest point of the booster riser. In a closed one - before supplying the cooled coolant to the boiler. In the latter case, it is necessary to correctly calculate the volume of the tank, and also observe the rules for its installation.

When tying a solid fuel heating boiler with polypropylene, steel pipes are first installed, and then polymer lines are attached to them. This is to prevent overheating of the polypropylene.

Tying electric heating boilers

The operation of electric boilers is built on a different principle than solid fuel or gas. The impact on water occurs due to heating the heating element or indirectly. Regardless of this, all piping circuits for an electric heating boiler must have one component - an electrical connection block.

It includes an RCD, an uninterruptible power supply device, and an automatic power regulator. All further equipment depends on the boiler model and its design. The easiest way is to do the piping of the heating boiler with your own hands, if it already has automatic operation control devices, an expansion tank and a circulation pump. But this is not always the case.

There is a special category of electrical heating equipment that do not have these components. These include electrode and induction models. In fact, they are only a heating element without additional operation control devices. In this case, the correct piping of electric heating boilers should be carried out according to the following rules:

- The size of the inlet pipes is taken into account. The diameter of the pipes must match their cross section. Otherwise, additional hydraulic resistance will arise;

- To control the temperature level, a thermometer must be installed. The same applies to measuring the pressure indicator, for which a manometer is needed;

- In the piping of a double-circuit electric heating boiler, an additional filtration system for hot water supply is provided.

In addition to these components, it is recommended to purchase a voltage regulator. Almost all types of alternative electric boilers are sensitive to voltage drops in the network.

It is necessary to include a heating pump in the piping only if the thermal expansion of the coolant cannot provide the proper level of circulation.

Features of piping of circulation pumps

A pump in the heating system is necessary for a stable circulation of the coolant, which would not depend on the degree of expansion of the water. It is installed according to the scheme at the point with the lowest water temperature - before it enters the boiler for reheating.

The piping of the heating circulation pump consists of two parallel heating circuits. This is necessary to ensure the smooth flow of hot water during a power outage. If this is not done, the resistance from the fixed impeller will worsen the already unsatisfactory indicators of natural circulation.

In practice, the following components must be included in the piping of the heating system circulation pump:

- Shut-off valves... With its help, the flow of water to a certain section of the line is shut off - main or auxiliary;

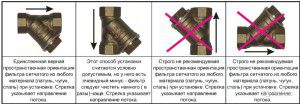

- Strainer... It is necessary to protect the impeller and pump rotor from the ingress of rust particles or sediment from the surface of the pipes.It is an obligatory component in the piping of the heating system pump, installed in front of it in the direction of movement of the coolant;

- Non-return valve on the auxiliary line... With natural circulation, the phenomenon of a change in the direction of movement of hot water is possible. To prevent this, a check valve must be installed in the piping of the heat supply pump.

These are the main components of the piping of the circulation pump in heating systems. If you need to install an additional one, you should purchase a synchronizer for stable operation of the pumps. It will synchronize the speed of rotation of the impellers, thereby minimizing the possibility of water hammer and periodic pressure changes in the heating system.

Before installing the pump in the piping of a diesel heating boiler, it is necessary to correctly calculate its power.

Radiator and battery piping

Radiators in a heating system are needed to transfer heat energy from hot water to indoor air. Therefore, special attention should be paid to their correct configuration and installation.

Possible options for piping heating batteries depend on the type of system. For an optimal configuration of a two-pipe circuit, you will need to install the following components:

- Shut-off valves... Installed on the inlet and outlet nozzles to shut off the coolant flow in the event of repair or replacement of the radiator;

- Thermostat... Installed on the supply pipe and is required to reduce (increase) the flow of hot water to the battery. The piping of heating radiators can do without it, but in this case it will be impossible to change the degree of surface heating;

- Mayevsky crane... Required to remove air locks. Installed in the upper branch pipe located on the opposite side of the inlet.

Almost all of these radiator piping components are implemented with the device. The only exception is the thermostat. It is best purchased separately based on functional requirements.

There are other options for piping heating batteries for a one-pipe system. The difference lies in the installation of a bypass - a connecting pipe between the supply and return pipes. It serves for the unimpeded passage of the coolant if it is necessary to disconnect the radiator from the general system.

The bypass design must include ball valves to shut off the coolant. During normal system operation, their state remains closed. If in a specific version of the heating radiator piping there is no thermostat, then you can use the tap to change the volume of the coolant inflow.

As an additional element, in addition to the heating radiator piping, you can install a reflective film on the wall. Thus, you can concentrate heat radiation towards the room.

General rules for piping

Correct piping of heating pipes consists in installing shut-off and control valves in certain sections of the system. But besides her, you need to install strainers in front of some devices - a circulation pump, an expansion tank.

To increase the period of maintenance-free operation of heating transport lines, additional components should also be installed. To a greater extent, this applies to polymeric materials of manufacture:

- Compensation loops... Needed in piping heating pipes to compensate for thermal expansion;

- Contours... Designed for the installation of intersecting pipes.

All other piping components belong to boilers, radiators and heating pumps.But what else do you need to know about the features of the complete set of heating components? It is important, even before the installation, to choose the right components so that during installation you do not encounter the problem of installing them together with heating devices.

In the video, you can familiarize yourself with the features of the heating boiler piping: