When equipping a home with a heating system on a gas boiler, the homeowner is faced with the issue of removing the waste products of combustion. The construction of a full-fledged chimney involves considerable financial costs and it is not always technically possible to implement a project. The use of a turbocharged gas boiler will help to avoid difficulties. This type of device does not need a chimney and gives more freedom of action.

- How a turbocharged gas boiler works

- The principle of operation of the equipment

- Performance Indicators

- Types of chimney ducts and features of their device

- Vertical chimney

- Horizontal smoke exhaust duct

- Two-channel vertical system

- Connecting the boiler to a regular chimney

- Pros and cons of turbocharged gas boilers

- What to look for when choosing a device

How a turbocharged gas boiler works

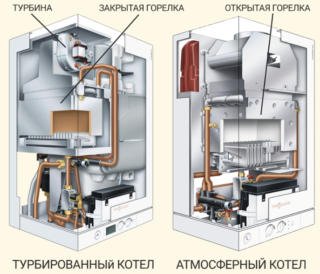

A turbocharged gas boiler is a unit that has in its design:

- channel for air intake and exhaust of combustion products;

- electric turbine;

- closed combustion chamber;

- one or more heat exchangers;

- multi-nozzle burner;

- pump for forced pumping of coolant;

- gas module;

- an electronic control system for the operation of the installation.

Depending on the capacity of the unit, heat exchangers and a burner of the corresponding size are installed on it. The larger they are, the larger the overall dimensions of the installation will be.

The body of the product itself, in which the listed elements are installed, is made of sheet metal. It has special mounting holes that allow you to fix the device on a vertical wall surface.

The principle of operation of the equipment

The turbocharged boiler works as follows:

- After energizing the unit and turning it on, the turbine fan is started.

- For a few seconds, a sensor in the pipe determines the strength of the air flow and, if everything is in order, gives a command to start the piezoelectric ignition.

- A few seconds after the appearance of a stable spark, a valve in the methane supply module opens, allowing the latter to enter the burner.

- A flame appears, which begins to heat up the heat exchangers with water.

- Upon reaching the set temperature in the system, a temperature sensor is triggered and gives a command to close the valve in the gas module.

This process continues in a circle in automatic mode, the operator can only adjust the required temperature of the coolant.

Performance Indicators

The most important performance characteristics of gas turbo boilers are:

- product reliability;

- durability;

- survivability of the unit.

The most vulnerable structural elements of any heater are heat exchangers and a burner, which are subject to constant heating. The former can burn out, while the latter periodically clog up the nozzles during operation. The faster and easier these faults are eliminated, the higher the performance of the model is.

Types of chimney ducts and features of their device

Engineers of methane-fired boiler equipment have developed several types of chimneys that can be connected to:

- vertical type;

- horizontal type;

- two-channel vertical design.

You can also always use an ordinary brick pipe as a chimney, having previously modified its design in accordance with the norms for the operation of boiler equipment.

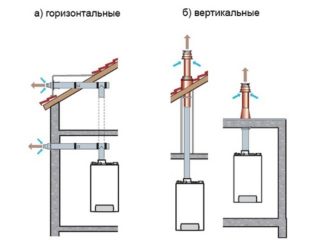

Vertical chimney

A single channel pipe is the simplest design. It can be made of stainless steel or galvanized steel. Such a chimney is assembled from separate sections of a thin-walled structure or with several walls, between which there is a layer of insulation. As a rule, this pipe system contains a settling tank for settling soot or condensate. The connection of heat-generating equipment to the channel is carried out from the side, just above the lower end.

Horizontal smoke exhaust duct

The horizontal type chimney can be single-channel or two-channel, called coaxial. The latter option is often used for boilers with a turbine, where the air is supplied from outside the building. The coaxial system can be made of stainless steel, galvanized and special plastic. The most reliable option is a stainless steel chimney, as it has increased resistance to the acidic environment resulting from the combustion process.

The inner duct of the two-channel system is outgoing, the outer one serves for air flow into the chamber.

Two-channel vertical system

A vertical pipe with two channels is most often used in multi-storey households with a centralized chimney system. Several units can be connected to such a pipe at the same time. A chimney project of this type takes place in houses where it is not desirable to weaken the supporting structure by drilling holes in the wall or in order to preserve the decorative facade of the building.

Connecting the boiler to a regular chimney

In old houses with built-in stove heating, you can use the existing brick pipe as a chimney for the heat generating unit. The disadvantage of this option is that the smoke, consisting of steam and carbon dioxide, does not have a high temperature, condensation will constantly form on the pipe, it will begin to freeze and quickly collapse. Therefore, such structures must be additionally insulated.

Pros and cons of turbocharged gas boilers

Boiler equipment with a built-in turbine has the following advantages:

- high efficiency reaching 95%;

- does not require the construction of a complex vertical chimney like atmospheric;

- has an increased level of safety, excluding the possibility of methane and carbon monoxide getting into the room;

- compact and does not require a separate boiler room for installation, like an atmospheric device;

- equipped with an automatic control system with the ability to operate from external temperature sensors.

The disadvantages of installations include:

- volatility of the unit, which cannot function in the absence of mains voltage;

- the high cost of both the equipment itself and the components if repair is necessary.

The choice of an atmospheric or turbocharged boiler depends on the technical capabilities of the building.

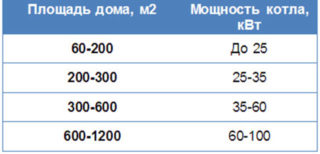

What to look for when choosing a device

When choosing methane boiler equipment, first of all, they are determined with a thermal power, which will be enough to heat a particular building. The standard ceiling height of up to 3 meters with an average insulation of the outer wall assumes a thermal energy consumption of 10 squares within 1 kW. You also need to consider:

- The single-circuit boiler is designed for heating only. To have hot water in the tap, a double-circuit is required.

- Devices with copper heat exchangers have proven themselves well - they are durable and quickly warm up.

- On the running models, there will always be an opportunity to find components and a service center for maintenance.

Modern devices allow you to control them through special applications in your smartphone.