Panel houses have thin walls and poor thermal insulation. For a comfortable life, you should make independent insulation on the balcony and in the loggia. It is forbidden to bring heating batteries into these rooms, so apartment owners are looking for other options for maintaining a comfortable temperature. Before starting work, you need to decide how to insulate the loggia from the inside, how to carry out the installation.

- Selection of thermal insulation materials

- Mineral wool

- Styrofoam

- Polyethylene foam

- Balcony preparation

- Waterproofing floors and walls

- Installation work on insulation from the inside

- Ceiling insulation

- Insulation of the floor using a lag

- Insulation of the floor with a dry screed

- Insulation of the walls of the loggia

- Balcony roof insulation with polyurethane foam

Selection of thermal insulation materials

The range of heaters in stores is wide enough. Before insulating the loggia from the inside with your own hands in panel houses, you need to familiarize yourself with the proposed product. Each material has its own properties, characteristics and operating conditions, so not all are suitable for installation on a balcony. The choice of an insulator for a panel house or Khrushchev is influenced by the planned heating system and the climatic conditions of the region.

Mineral wool

The traditional insulation, which has been tested by time, is mineral wool. It is actively used today in a modernized form. Available in fiberglass, slag and stone forms. It is sold in the form of mats and rolls with a thickness of 20-200 mm.

The main advantages include the plasticity of the material, the ability to cut with an ordinary construction knife and good sound damping. When working with insulation, you need to select in advance personal protective equipment for the skin of the hands, face and respiratory tract. Special care must be taken when working with glass wool. Its small particles can get on the skin and mucous membranes, resulting in irritation and itching. The most harmless type of mineral wool in work is stone basalt wool.

Styrofoam

Foam is one of the most affordable materials. It retains heat well and is easy to lay on flat surfaces. It has good sound insulation properties and is light in weight. On sale you can find polystyrene of different thicknesses and densities. The higher the density, the worse the thermal insulation. But working with high density is easier. If another denser material (plywood) will be applied as the top layer, you can take a loose foam.

If wall alignment is required, it is better to take extruded polystyrene foam. In terms of chemical composition, it is analogous to polystyrene, but it is produced using a different technology. Does not undergo deformation and mechanical stress. It is often used for floor insulation. It is more expensive than regular polystyrene, but it does not take much to lay it on the balcony floor.

Polyethylene foam

Release form - mats and rolls of different thickness. The thinnest type is used for installation under a laminate, and the thickest one acts as an independent insulation.

There is a kind of polyethylene foam with a foil surface. It is characterized by increased efficiency, since the mirror surface reflects the heat flux in the desired direction.

Balcony preparation

The first stage is the preparation of the premises for work.

- Cleaning the surface from cement, paint and other irregularities. The working wall or floor must be smooth, otherwise the insulation will be difficult to install.

- Cleaning of dust and debris from the floor. All dirt must be carefully removed with a vacuum cleaner so that it does not get into cracks.

- Sealing of internal holes, joints, cracks. Large cracks are filled with sealant or cement mortar. The gaps between the plates are removed with polyurethane foam.

- Removal of excessively set foam, sealant. Coating the surface with a primer.

Next, you can proceed to waterproofing surfaces. A properly applied protective layer will protect your home from mold.

Waterproofing floors and walls

Waterproofing is required for the floor and the bottom of the walls. The height depends on the level to which the floor covering will be raised.

The main ways to create waterproofing:

- Laying roll-up waterproofers. The most popular material is roofing felt. It is glued onto bituminous mastic.

- Impregnation with special means. Suitable for concrete and brick surfaces. Not suitable for tiles. You need to work with the compounds with gloves so as not to get burned.

- Liquid rubber. Suitable for tiles. After drying, it creates a film that protects the balcony or loggia from external moisture.

- Plaster mixes. Used for concrete surfaces. Applied with a spatula.

- Coated with thick oil paint. Used for tiled walls.

- Laying thick plastic wrap. It is attached to the floor and the lower part of the walls.

Any of the above methods allows you to protect the balcony from moisture and the formation of mold and mildew.

Installation work on insulation from the inside

After the waterproofing layer has dried, you can begin to insulate the balcony. For this, lathing is used on the walls and floor. Thanks to it, installation can be done easily, quickly and conveniently.

Traditionally, insulation starts from the ceiling. Next, the floor and walls are insulated. Which insulation is best for the balcony inside depends on the evenness of the surfaces, climatic conditions, budget, and the availability of tools.

Ceiling insulation

Thermal insulation work is carried out in different ways, which depend on the type of insulation chosen. To create an additional substrate, a layer of foil-clad polyethylene foam can be laid under the lathing. It is fixed on double-sided construction tape or glue. For additional insulation of wall and ceiling joints, it is recommended to wrap the sheets by 150-200 mm. The layer must be fastened securely so that it holds until the sheathing is installed.

The next stage is the installation of the lathing. It is made from wooden blocks or metal profiles. The distance between the elements should be equal to the width of the insulation for the loggia so that it fits snugly inside the crate. If mineral wool is used, the spacing can be shortened by 30-50 mm.

Thermal insulation is placed in the formed cells. In the case of using mineral wool, additional fixation is not required, since the material is distinguished by its rigidity and fits tightly between the bars. When laying the foam, it must be borne in mind that gaps may form between the material and the batten. They can be sealed with polyurethane foam. Then the insulation is covered with sheets of drywall or clapboard along the sheathing guides.

If extruded polystyrene foam is used, it is fixed directly to the ceiling. You can fix the mats on special plastic mushrooms. To install them, holes are made in the surface, into which a fungus is then placed and where a plastic nail is hammered.

Insulation of the floor using a lag

The floor insulation algorithm also depends on the type of insulation. A dry screed is applied, raising the floor on logs or flooring of extruded polystyrene foam directly on the concrete surface. The latter method does not give the expected effect, but simply reduces heat loss.

The use of a lag is the simplest and most effective way to insulate floors. Logs can be laid on concrete or raised to the desired height using metal holders. For a loggia of standard sizes, three rows of lags are installed.

The holders are fixed on the concrete base, after which the insulation is laid on them. Usually, mineral wool is additionally used for such fastenings. A square is cut from it, in which two holes are made. Through them, the heat insulator is put on the rack.

After fixing the lag, the main insulation is laid on the entire surface. On top, you can lay another layer of mineral wool, which should be raised almost to the level of the log.

The last layer is the laying of a vapor barrier. It is attached to staples. At the end, the final floor covering is laid. Plywood 10 mm thick is screwed onto the logs. The cracks between the wall and the floor are sealed with foam. Linoleum or other decorative coating is placed on top.

You can insulate the floor using metal or plastic supports. They are height adjustable. They are used when the floor surface is uneven. Logs are attached to the adjustable stands, after which they are placed on the floor and leveled in height. The subsequent operation algorithm is similar to the installation of conventional lags.

When the installation of adjustable stands is not possible, you can make a crate installed on stands from bars. The wooden structure is more difficult to deliver when the surface is uneven. The lathing must be fixed on the walls of the loggia.

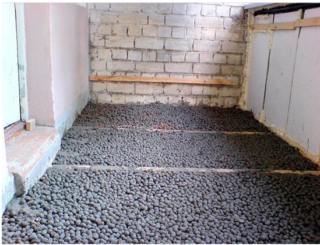

Insulation of the floor with a dry screed

For insulation, a bulk floor is often used, consisting of expanded clay crumbs and gypsum fiber boards. Laying can be done in two layers.

To carry out the installation of such a structure, temporary beacons are placed on the waterproofing to level the mixture according to their level. An elastic damper tape should be attached to the walls in order to protect the coating from the effects of temperature fluctuations. The complexity of the process lies in the need to work in a confined space. In addition, you constantly need to control all stages of backfilling using a building level.

The next stage is the laying of the slabs. They are laid from the corner of the balcony onto the grooves, which should be coated with liquid nails. The tiles should be stacked on top of each other to form a solid coating. After the panels have been laid, all gaps between them and the walls should be sealed with polyurethane foam. Any decorative coating can be applied to the resulting hard surface. This method is suitable if a warm floor is installed.

Insulation of the walls of the loggia

The main methods of insulating the surface of the walls on the balcony include:

- use of lathing;

- installation of a rigid heat insulator.

Depending on the chosen insulation for the walls for the balcony, the laying algorithm will differ.

To install a rigid insulation (for example, penoplex), it is enough to apply an adhesive to the back side. The panels must be pre-selected in size so that they can be conveniently installed. The tiles are glued to the wall and fixed with plastic mushrooms for reliability.

The most popular thermal insulation method is the wall sheathing. This method is convenient in that any thermal insulation material can be fixed on the bars or metal profiles from which the cells are made.

Before installing the crate, it is recommended to cover the walls with foil-clad polyethylene foam. The efficiency will increase and the heat will remain on the balcony or in the loggia for a long time. A crate is placed on top at a distance equal to the width of the heat insulator mats. After that, the insulation itself for the balcony is laid in the formed cells. A vapor barrier is placed on top, which must be attached to the staples.

The final stage is covering the outside with a decorative coating.It can be a lining, a base for painting, drywall and other materials for balcony walls.

Balcony roof insulation with polyurethane foam

For additional thermal insulation, the roof of the balcony on the top floor can be insulated. This method is often used in cottages, but due to the convenience and ease of installation, it can be used in the loggias of apartment buildings.

Warming is actively used by spraying polyurethane foam. The process will require special equipment, so you should call specialists from specialized companies. The surface is preliminarily prepared and the crate is made. It acts as a frame for a sprayed thermal insulator and decorative finish.

The main advantages of spraying include the sealing of holes and crevices. In the process of spraying, the material expands and closes all holes, after which the surface becomes windproof. Polyurethane foam can be used for roofs, floors, ceilings and walls. Among the shortcomings, one can single out the costs of calling a master or buying professional equipment.