Insulation of slopes is one of the parts of the procedure for arranging housing, which together allows you to create a comfortable and healthy microclimate in it. This activity is quite simple, it does not require professional skills and tools. You can do it yourself, keeping within a limited estimate. To achieve a high-quality result, you need to study the features of commercially available materials and the technology for their use.

Causes of condensation

Condensation formed on the walls and frames is the cause of high humidity in the apartment. Due to dampness, fungus and mold begin to develop. Shoes, clothes and furniture quickly deteriorate, there is an unpleasant smell in the air. All this is fraught with material losses and health problems.

Reasons for the appearance of condensation:

- The window frame does not fit tightly to the opening, there are technological seams, which are filled with polyurethane foam or cement mortar. Cement is an excellent conductor of cold, and foam quickly degrades under the influence of moisture, temperature changes and ultraviolet radiation.

- The double-glazed window cools down strongly in the cold, through the frame the cold is transmitted to the walls. If there is no insulation gasket, the supporting structures cool down and water droplets form due to the temperature difference.

- Over time, the building shrinks, which leads to the formation of through cracks through which cold air enters the room and to the walls.

Competently executed insulation of the slopes of plastic windows from the inside and outside will help get rid of excess dampness and have a positive effect on the design of the room.

The choice of material for thermal insulation of slopes

When choosing a material, one should focus not only on its cost.

It is necessary to use thermal insulation that has the following characteristics:

- low thermal conductivity;

- durability;

- shape stability;

- immunity to temperature extremes;

- low hygroscopicity;

- resistance to mold and mildew.

It is possible to insulate the slopes of plastic windows inside the apartment and from the side of the street with the following materials:

- Styrofoam. It is produced in the form of slabs 100x100x2 cm. Differs in an affordable price, lightness and ease of processing. The disadvantage is that the substance absorbs moisture and, under its influence, loses its properties, slowly turning into dust.

- Extruded polystyrene foam is the most effective insulation among slab counterparts. Penoplex does not deteriorate from dampness, it is immune to pressure and pathogenic microorganisms. It is great for outdoor and indoor use.

- Mineral wool. It is produced in rolls and plates, 50 mm, 100 mm and 150 mm thick. The material conducts air well. Minvata can be used to insulate a wooden and frame house, where ventilation qualities are appreciated. Since the insulator is hygroscopic, it must be insulated with a membrane cloth, followed by covering with plastic panels or plastering.

- Polyurethane foam. It is a liquid substance that, upon contact with air, increases 30-40 times, filling all cracks and cavities. Cured foam is characterized by low thermal conductivity, resistance to dampness and temperature extremes. The disadvantage of polyurethane foam is that under the influence of ultraviolet radiation, it quickly collapses.

- Sandwich panels.They are an excellent option for finishing slopes both outside and inside. The foam enclosed between PVC plates is protected from external influences and effectively retains cold. During installation, it is necessary to properly seal the ends of the panels in order to securely close the filler.

- Warm plaster. Combines the qualities of foam and putty. Due to its liquid state, it fills all voids, forming a solid frame for the window. After drying, it is a reliable temperature barrier between the street and the room. Strengthening the insulating properties of the solution is achieved by adding a variety of foam balls, ceramic and polymer additives.

Thermo-otkos can be created from several types of insulation, if it is necessary to achieve a high-quality result in all respects.

Insulation tools and materials

To make an insulated window slope, you need to prepare the following tools:

- puncher;

- level;

- roulette;

- hacksaw;

- miter box;

- stationery knife;

- marker;

- paint brush;

- putty knife;

- grater;

- assembly gloves;

- protective glasses.

You need to purchase the following materials:

- synthetic or rubber glue;

- putty;

- facade plaster;

- deep penetration primer;

- water-based paint;

- antiseptic;

- reinforcing mesh;

- thermal insulation.

Depending on the selected technology, the lists can be larger or smaller.

When calculating building materials, you need to make a margin of 10-15% for errors, losses during transportation and storage.

The process of insulating the slopes of plastic windows inside the house

Insulation of window slopes from the inside should begin with the preparation of the base.

It is recommended to carry out the following actions:

- clean the space between the frame and the opening from the old finish and filler;

- align internal openings with a punch;

- remove dirt and dust from surfaces with a brush and a spray gun, wipe off oily deposits;

- seal visible cracks and holes with cement mortar or mastic sealant;

- treat the surface first with an antiseptic, and then with a deep penetration primer;

- perform sealing.

Further actions can be carried out when the base dries well. This time can be spent on warming the space under the windowsill and ebb. It, like the slopes, must be well cleaned of dirt and dust, and then filled with one of the available thermal insulators.

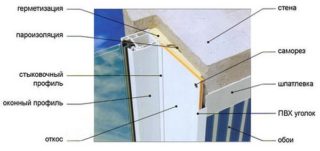

After that, you need to carry out the following manipulations:

- Align the openings so that they have the correct geometric shape. To do this, you can use polyurethane foam, gypsum mortar or facade plaster.

- Treat the openings with an antiseptic, impregnation and hydrophobic agent.

- Take insulation, cut strips of the required width and length from it. When making blanks from basalt wool, you need to take into account the elasticity factor and make them 2-3 cm larger.

- Prepare waterproof adhesive and apply generously to the strips. Immediately after that, with effort, insert them into the cavities, distributing them throughout the volume. Remove excess adhesive.

- Make a second set of warm blanks. They must be done with the expectation that they will cover the surfaces between the frames and the inner sections of the wall.

- Stick the thermal insulator over the previously sealed openings. Remove protruding excess, cut corners.

- If mineral wool is used, cover it with a membrane and cover it with a vapor-permeable solution.

The final stage is finishing. Slopes are covered with plastic, plaster or ceramic tiles.

Thermal insulation from the side of the street allows you to move the dew point away from the supporting structures. This will extend their service life and improve the insulating qualities of the slopes.For work, it is better to use expanded polystyrene, which has all the qualities necessary for operation in the external environment.

External insulation is carried out in the following sequence:

- Measures are taken to ensure safety when working at height. Insurance is required, the rope is attached to the radiator or to a special hook screwed into the wall for the period of repair.

- A double-glazed window is removed from the blind frame and taken out of the room. It is better to involve an assistant here.

- The area around the perimeter of the window is cleaned of dirt and degreased.

- At a distance of 20-25 cm from the outer edges of the slopes, a 20x20 mm plastic corner is attached.

- Strips of expanded polystyrene are cut to the size of the outer frame and slopes. The workpieces are glued at the designated places, after which all the cracks are sealed.

- The overlays are rigidly fixed with disc dowels at intervals of 40-50 cm.

- Reinforcement of the surface of the insulation is carried out using a plastic mesh.

- A layer of facade plaster up to 15 mm thick is applied.

The final stage of the repair is surface finishing. For this, paint that is resistant to moisture, frost and ultraviolet light is used.

The wider the profile, the better and more its thermal resistance. Accordingly, the window will be warmer. Usually the profile has three standard sizes: 58mm, 70mm, 82mm. The narrowest profile doesn't suit us. It is the coldest and its width is not enough to put a warm glass unit. Profile 82mm wide. the warmest, it is also the most expensive. If the budget allows, then you can safely buy this option.